“In 1985, my family and I left Scotland for sunnier climes,” Alan Henderson, operations manager at the Blue Sea Food Company, told Fishing News. “We upped and moved everything – sold the house, put all our goods in a van on a one-way hire, and drove down to Devon. One of the first guys I met down here was Trevor Bartlett.”

That meeting with Trevor Bartlett – who sadly passed away earlier this year – proved instrumental in shaping the course of Alan’s career, much of which was spent working with Trevor, both on land and at sea.

“Within six months of moving down, Trevor looked me up and down and asked: ‘Have you ever been to sea?’ I said I hadn’t, and that I was from farming stock in central Scotland. Trevor said: ‘We’re the same – fishermen are farmers of the sea.’

“Janet, my wife at the time, and I chatted at length about going to sea, and on the assurance from Trevor that we would be multi-millionaires within five years, we jumped at the chance.”

Alan’s first trip proved a success, and with Trevor’s new crabber, the Euroclydon, just months from launch, it seemed a career at sea beckoned.

“We were all really excited about taking on the new boat and becoming multi-millionaires. We never did achieve that – but I’ve been with Trevor through thick and thin. We’ve had our differences, and I’ve gone off and done other things, but I’ve stuck with him right until when he passed away.”

Following spells transporting crab, building a langoustine supply business with Trevor, and helping his son Shaun set up his own successful seafood company, Henderson Seafood, Alan ultimately returned to where it all started – crab.

“In 2004, Trevor set up the Blue Sea Food Company for the processing of crab. The company had state-of-the-art cooking facilities, but no supply of crab. My remit was to go out and buy crab.”

Since then, the Paignton- based company, which was acquired by American firm New England Seafood International earlier this year, has gone from cooking 600kg of brown crab a week to 15t a day. For Alan, ensuring the steady supply of crab is still a crucial part of his role – along with the smooth running of the factory.

Alan finishes his day at the factory with a three-mile cycle home – but that doesn’t signal the end of his working day. “I try to get home around 6pm to 7pm. However, I can be on call during the night. I could get a phone call from a driver in the middle of the night if, for example, they have a problem with customs coming in through Dover.”

“The factory opens and starts cooking at 6am. All the machinery has to be up and running by then, with the boiler on and the water hot. So I’m in at 5am, to make sure there aren’t going to be any hiccups.

“I’ve got alarms on everything. The boiler is started automatically during the night – but I get notifications, and can tell immediately if there’s a problem.

“I also need to make sure that the factory is fed crab in a specific order, as we’re dealing with such a large amount, which can come from quite a few different sources – and because we want to keep traceability, the factory needs to know which boat or merchant is which. It’s all logged and documented.”

As well as ensuring the day’s processing goes to plan, Alan has to plan ahead. “We buy from Holland, the North East of England, Ireland… so it can be a challenge logistically. You have to level it out – the factory wants 15t of crab every day, and that first piece of crab has to be there at 6am. You’re taking a lot of variables and trying to plan it out for a level supply – which can be trying and testing at times – but I love doing it.”

Having been with the company since its incorporation, Alan’s knowledge and experience can see him called upon to help out with a wide range of tasks.

“The factory has really intricate pieces of kit. We have a machine called the spin-sheller – where you put the carapace of the crab into what is a bit like a washing machine sitting up on its end. The machine extracts the meat using centrifugal force. It’s a highly engineered piece of equipment – and I love that machine.

“Our engineers still come to me now and ask me to take a look at the machine if it isn’t working properly. So I can be called into the factory for something like that. We also have a bespoke cooker, and sometimes the engineers will ask me to look at that.”

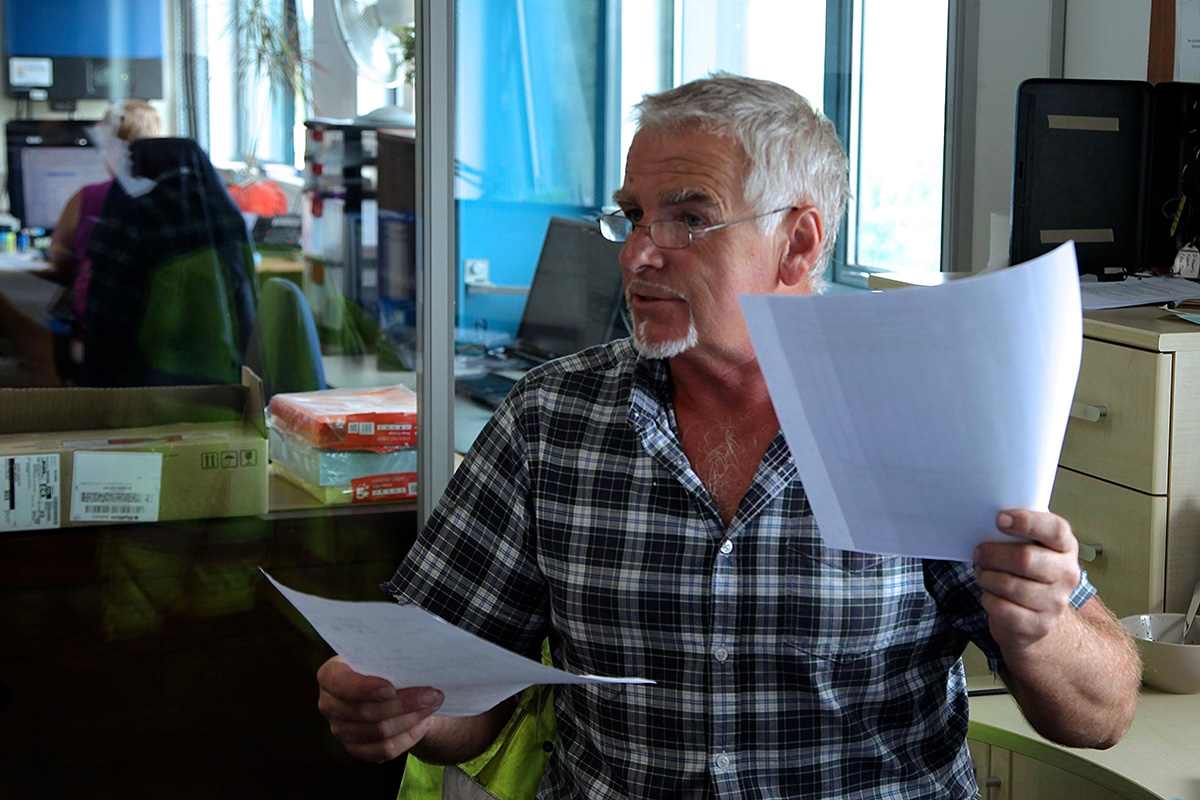

Alan’s day also sees him deal with a wide range of administrative duties and paperwork – from supplier allocation returns to working on innovations to ensure a future brown crab fishery.

“I have a desire to do something about sustainability. Three of my immediate family are in the industry, and I want to make sure they’re still going to have a fishery in 20 years’ time.

“I’m busy trying to set up a crab hatchery down here. I’m very keen to do something to reverse the downward trend of the crab catches. If we don’t do something, especially in the Channel here, we will lose the fishery completely. I’m hoping I can get the hatchery off the ground.

“Whether it will make a difference, we don’t know – but you’ve got to try.”

This story was taken from the latest issue of Fishing News. For more up-to-date and in-depth reports on the UK and Irish commercial fishing sector, subscribe to Fishing News here or buy the latest single issue for just £3.50 here.

Sign up to Fishing News’ FREE e-newsletter here.