As the 2020 North Sea seasonal herring fishing gathers momentum, David Linkie looks back 13 years to a trip on the new Fraserburgh midwater trawler Chris Andra FR 228

With the 2007 summer herring season drawing to a close, Chris Andra sailed from Peterhead late on the second Saturday in August, in the knowledge that apart from Taits, which was scheduled to leave Fraserburgh a couple of hours later, most of the Scottish pelagic fleet were tied up, having already taken their allocation of North Sea and west coast herring.

Chris Andra approaching Peterhead to land 430t of herring.

Steaming north past the St Fergus gas terminal, skippers Peter and Willie Tait observed that a key feature of the recent herring fishery had been the small number of boats at sea at any one time. The main reason for this was the voluntary agreement by skippers to stagger their fishing times. This well-balanced fishing effort gave the mutually beneficial advantage to catchers and buyers of ensuring that supply levels were always in line with the requirements of processing factories at Peterhead, Fraserburgh and Lerwick.

A second equally important benefit was that staggered fishing allowed processors to handle catches over the longest possible timescale, thereby extending the length of their processing season.

Some Scottish boats were tied up by mid-July before their counterparts started fishing, while as usual, the Shetland pelagic fleet did not make a move until the middle of August.

Shooting away the Jackson 1,050m herring trawl off the lower forward net drum.

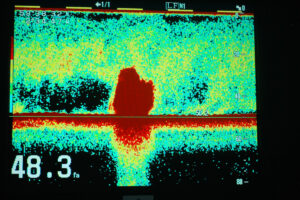

A good mark of herring displayed on the Furuno FCV1200L sounder, operating on 50kHz.

Drying up the bag after a successful first haul…

… that yielded 280t of herring.

Preparing to pump herring onboard Chris Andra as darkness comes in.

Chis Andra’s crew stand by at the transom to release the pocket and bag.

Starting to run the bag.

Shooting the net off the lower drum.

Clipping on the lower starboard sweep.

Willie Tait oversees shooting away the gear from Chris Andra’s trawl console.

While steaming the 140 miles north from Peterhead, 800t of seawater, pumped into Chris Andra’s 10 RSW tanks midway across the Moray Firth, were chilled from an ambient temperature of 13oC to the optimum catch storage level of -2oC in six hours. This rapid rate of large-scale cooling showcased the level of specification to which Chris Andra was designed and built, and in particular the capability of the two MMC Kulde refrigeration plants, which delivered 1,000,000kcal of cooling capacity per hour. The specification of this system was key to achieving the owners’ requirement of delivering the highest possible standard of pelagic fish to Scottish processors, working in an extremely competitive global marketplace in which customers were stipulating an ever-higher standard of end product.

Dawn the following morning saw Willie and Peter Tait concentrating intently on the sonar displays as searching began west of Noup Head, on grounds where Chris Andra had landed a large class of herring when last at sea two weeks earlier.

The latest array of acoustic equipment, to track herring from the point of initial detection until they passed down the tunnel of the trawl, was to hand in Chris Andra’s wheelhouse.

The advanced Furuno FSV24 24kHz sonar had the capability to detect fish up to distances of 2,000m, depending on the bottom. On peaky ground, the range was usually reduced to 1,000m or less, to help differentiate between echoes from fish and rock pinnacles. On this trip, it was mainly used on the 1,000-1,500m range to give early indication of suitable marks, before the range was decreased to track marks back to the boat, where fish were shown on the Furuno FCV1200 and Simrad EQ60 MK2 dual-frequency vertical sounders. These covered the 24kHz, 50kHz, 110kHz and 200kHz frequencies, with the second-lowest being the most successful for marking herring.

Using information relayed back by cable to Chris Andra from the headline sensor, the Wesmar TCS380 trawl sonar/sounder gave a clear indication of fish entering the mouth of the trawl, in addition to a constant readout of the headline height.

Chris Andra’s second net-monitoring system, a cableless ScanBas pelagic system, displayed the quantity and flow of fish entering the tunnel of the trawl, ensuring that the skippers had a continuous knowledge of what was happening to some £100,000 of fishing gear and sensors behind the trawl doors.

Information on tide runs at varying depths – which have to be allowed for when lining up a mark – came from a Furuno CI60G Doppler current indicator.

Two hours after starting to search, some promising small but strong marks appeared on the sonar screen, and after tracking the fish, Chris Andra’s 10-man crew were called on deck to shoot away the midwater trawl.

Chris Andra was using a new design of 1,050m midwater herring net supplied by Jackson Trawls – further strengthening the Peterhead netmaker’s long association with the Klondyke Fishing Company.

The net was a longer wing version of the herring trawl that the Klondyke Fishing Company’s vessels had been using for some time. The 12.8m meshes in the top and sides of the trawl were made from Van Beelen Stealth twine, the pleated nylon construction of which can be spliced to enable the gear to retain its shape better. In the lower section of the net, 6.4m meshes were used, made from standard braided nylon, which skippers Peter and Willie Tait favoured for taking fish off the bottom. Increased use had been made of smaller mesh in the tunnel of the net, and the skippers felt that this feature contributed to its excellent overall performance.

The success of this midwater herring trawl can be gauged from the fact that Chris Andra took her quota using only one net without breaking a mesh – a fact much appreciated by the crew.

Chris Andra used 60-fathom 36mm-diameter Dyneema SK75 polyester-covered sweeps to attach the trawl to the NET Systems Extra-Lite 12.85m2 midwater trawl doors. Generally using single 1.35t toe-end weights, Chris Andra typically achieved a horizontal opening of 55 fathoms and a vertical opening of 18 fathoms when towing the 1,050m herring trawl at 4.5 knots.

With 350m of 38mm-diameter Oliveira wire shot in 40 fathoms, Chris Andra was towing at 4.5 knots with 80% pitch on the 3,800mm-diameter propeller. Fishing in relatively shallow water, the Bergen B32:40 L9P propulsion engine was running in the lower power-step mode to deliver 4,400kW @ 675rpm to the Kamewa Ulstein 4.1:1 reduction gearbox, to give a propeller speed of 165 rpm. The Rolls-Royce AS autotrawl system was indicating a wire tension of 18t.

After towing for 20 minutes back to the location of the main mark that led to the trawl being shot, only small bits of marks appeared on the sonar display. With the Doppler log indicating 0.2 knots of tide running on the bottom, it was thought that the slack water might have helped the fish to move. Forty minutes into the tow this thinking proved correct, as the sonar started to show a good mark, nearly a mile away from where the original mark was plotted.

With total concentration and continual adjustments to the sonar range, Willie Tait tracked the mark back to the boat when it appeared on the sounder displays. Chris Andra was 0.45 miles ahead of the fish before the Wesmar net sonar started to show them entering the trawl. Further indication of initial success came when the first catch transducer, positioned to activate at 50t, was triggered. By now, the Scanmar ScanBas system was showing herring passing successfully down the tunnel of the trawl, as a series of viable but smaller marks were lined up on the sonar.

Thirty minutes after the activation of the second egg indicated that 200t of herring were in the brailer, Peter Tait changed from auto-trawl mode to heave on the Brattvaag syncro autotrawl system. The Rauma Brattvaag 72t split trawl winches quickly had the NET Systems trawl doors hanging at the gantry, enabling the crew to clip on the G-links of the helper pennants, before the forward and lower 71t net drum started to wind on the sweeps and wings, once the single 1.35t toe-end weights were stored in their deck racks.

As the 67t lifeline winch shortened the dogrope in and the bag was dried up by the net drum before the midline choker was attached, the net appeared heavy, with little indication from the surface of the quantity of fish it contained. Hauling showed the benefits of Chris Andra being fitted with a low-pressure (64 bar) hydraulic system using large-diameter pipes, as there was no discernable noise from the powerful array of deck machinery.

The 45t tail-end winch took the bag forward to the midships gallows, enabling the lifter to be clamped in position over the 18in inlet of the 24in Karm fish pump, which was capable of delivering 12t of fish per minute (720t per hour) to the MMC Tendos fish/water separator.

As there was clearly a considerable weight of herring in the net, Chris Andra’s crew used their experience to lower the pump slowly to a suitable position relative to the brailer, ensuring that not too many herring were allowed to move suddenly en masse towards the pump – which could result in choking the pump.

As the fish/seawater ratio increased, prime herring were soon flowing down the chutes into the selected RSW tanks. Forty minutes later, when the pump was raised and released from the lifter, there was an estimated 280t of herring onboard Chris Andra – which would be confirmed a few hours later when the tanks could be dipped accurately after the fish had settled.

Peter and Willie Tait were particularly impressed with the performance of Chris Andra’s new design of fish/water separator, which they said delivered an improved quality of pelagic fish in addition to being faster.

On commencement of pumping, several baskets were filled with herring and taken forward for sampling, with each fish being electronically weighed. The computerised results, which gave a catch average of 285g, were subsequently printed off in the wheelhouse and transmitted ashore so that processors had full information on the herring they would be buying, including the time and location of catching.

Following the first tow, Chris Andra steamed 20 miles further west before searching began again. After an hour of little activity, a number of interesting marks, alternating between spreads along the ground and some more solid marks, started to show in deeper water. The gear was shot away at 2.30pm, by which time 0.6 knots of tide was running into the WSW. Fifty minutes elapsed before the first signs of fish started to show.

With the fairly high-standing marks tending to flatten and spread out on detecting the turbulence created by the trawl wires and doors, the skippers used all their experience to play out a delicate balancing act to keep the footrope of the midwater trawl skimming as close as possible to the bottom without making contact. Having initially shot 550m of wire in 73 fathoms of water, the warps were shortened to 420m as the bottom shoaled up to 65m.

Two hours into the tow, the first catch sensor triggered. With no more marks appearing ahead, Peter Tait brought Chris Andra around to head up to the main run of fish for a second time, when again the net-monitoring systems marked fish entering the mouth of the net and moving into the tunnel. This included one good mark that showed for several sweeps on the Wesmar trawl sonar. After a three-and-a-half-hour tow, the decision was taken to haul at the same time as the second egg came on. Although slightly smaller than the first, the second haul took the total for the day to over 400t.

With darkness in less than three hours, the skippers were keen to shoot away again for a third tow as quickly as possible, in order to complete Chris Andra’s west coast quota. Rather than tracking marks first, the gear was shot away before Chris Andra towed into the northeast towards the area where the fish were taken on the previous haul. However, marks proved evasive, so a short tow for nothing was concluded as darkness closed in.

With one vessel, the Barra midwater trawler Prowess, scheduled to land herring to Denholms at Peterhead on Monday morning, and with Taits having found fish scarce further west, the decision was taken to stay out for another night before taking a look closer towards Cape Wrath the following morning.

Although herring are often taken in the vicinity of Solan Bank and Whiten Head from mid-August onwards, the marks seen were isolated and considered too small to shoot for, given that Chris Andra had sufficient fish aboard to meet the requirements of Denholms and Pelagic Freezing (Scotland) Ltd at Peterhead – the usual outlets for the Klondyke Fishing Company.

After searching for five hours while slowly heading east, Taits reported taking a shot of fish west of the Cape that was sufficient for both boats to complete their west coast herring quota.

As a result, the sonars were switched off and the speed was increased to enable Chris Andra to round Duncansby Head in a six-knot tide at 4pm as cook Lewis Duthie prepared beef curry for supper – the last in a succession of fine meals.

Later that night, Chris Andra’s crew shot the midwater herring trawl off the net drum in the Hole of the Broch off Fraserburgh, before taking it back onboard and tying up the wings in preparation for putting them into the net store and replacing them with larger midwater trawls for the start of the western mackerel fishery on 1 October.

By 6.30am, Chris Andra was alongside at Peterhead to start discharging 430t of herring which, after filleting and freezing into a variety of products, would be loaded onto reefer ships at Peterhead for export to international markets in the coming months.