Stonehaven static-gear skipper Ian Mathieson, and crewmen and Buckie brothers Neal and Derek Clarke, fished their first crabbing trips on the new 14.6m potter Dalwhinnie A 913 towards the end of last month, reports David Linkie

Built to a high level of specification and featuring a number of innovative ideas, the new boat reflects the detailed thinking and quality workmanship that the owner and boatbuilder put into the design and fitting out of the GRP hull.

Built by G Smyth Boats Ltd of Kilkeel and insured by Sunderland Marine, Dalwhinnie replaces skipper Ian Mathieson’s previous boat of the same name, a Cleopatra Fisherman 42, which is now for sale after being re-registered AA 913 (Alloa).

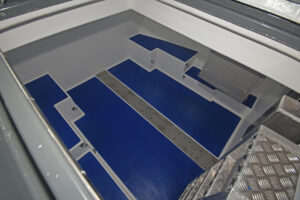

The crabber’s extensive working deck.

While waiting to receive Dalwhinnie’s fishing licence, skipper Ian Mathieson said: “There is a marked vibrancy in the creel industry at the moment, directly associated to healthy stocks and buoyant market demand, particularly for brown crab. This, in turn, has attracted significant levels of investment in modern landing and processing facilities in recent years. It has also encouraged skippers to invest in new boats, as our sector of the fishing industry looks to the future.

“From a personal perspective, it was time to move forward, and to build on the consistently successful level of performance the previous boat returned for eight years, since being built in Iceland by Trefjar Ltd in 2011.

Dalwhinnie skipper Ian Mathieson.

“Various options were considered and evaluated when the decision to go for a new boat was made. Clearly, moving to a heavy displacement hull from a semi-displacement one represents a considerable change. That the new Dalwhinnie weighs 50t, five times more than her predecessor, immediately illustrates the difference between the two boats.

“The new boat immediately showed her seakeeping qualities during some scruffy weather on the first half of the delivery passage home from Kilkeel. The weather was on the broad when crossing the Irish Sea, and later on the bow off the coast of northwest Scotland, heading towards Cape Wrath. Regardless of which direction, Dalwhinnie handled the conditions comfortably, covering 700 miles in just over three days at sea.

A spacious engineroom is a particular feature of Dalwhinnie.

“From the initial contact with Gerry Smyth, the complete design and build process has gone extremely well. The only specific remit I gave him, which he readily agreed to, was that stainless steel must be used throughout, with a complete absence of any ferrous material, to ensure minimum levels of maintenance in years to come.

“Attention to detail was a recurring theme throughout the build, when Gerry’s entire team were extremely accommodating. Whenever decisions needed to be made, they always went for the next level up. From the perspective of engineering, fabrication and internal fit-out, I’m totally delighted with the end result.

The 130-box-capacity dry hold is fitted with a refrigeration unit to keep shellfish in optimum condition.

“The quality of workmanship is self-evident, and in my opinion, the Kilkeel boatyard is one of the best in the UK. The degree of co-operation and the quality of the build are second to none.”

Dalwhinnie is based on a Buccaneer 46 displacement hull, which was moulded by Paul Ching in Roche, Cornwall, before being delivered across the Irish Sea to Kilkeel as a bare hull for full machinery installation and fit-out in G Smyth Boats’ modern boatbuilding premises.

The superbly finished and well-equipped galley…

The main dimensions of Dalwhinnie are LOA 14.65m, beam 5.2m, draught 2.26m and GT 18.65t.

The round bilge GRP hull incorporates a soft nose stem, a bulbous bow, a transom stern and a bold sweeping sheerline. Stainless steel cappings and safety rails are fitted along the entire length of the deep gunwales from stem to transom, to enhance crew safety on deck.

A short section of deck shelter is fitted abaft the wheelhouse on the port side, to give added shelter when accessing the heated protective clothing compartment on the main deck, as well as the deck crane and forward pressure washer reel.

… is arranged forward of three bunks positioned under the wheelhouse floor.

When viewed in profile, the measures taken to complement Dalwhinnie’s bold sheerline are immediately obvious. These include the sweeping roof lines of the wheelhouse and walk-in engineroom access deck compartment aft, the fore side of which is also raked to enhance the vessel’s streamlined appearance.

Rigged for self-hauling and shooting, Dalwhinnie is the biggest new vessel to be completed at the Kilkeel yard since the similar-sized vivier-crabber Álsviør K 337 was delivered to Orkney owners four years ago.

General view of hauling arrangements and the internal return pipe.

Skipper Ian Mathieson and his crew mainly fish a combination of 36in and 30in double hard-eyed D-section parlour pots manufactured by Caithness Creels of Wick, when fishing down to 40 fathoms. Spaced at 10-fathom intervals on 16mm-diameter Eurosteel, sourced exclusively from Euronete UK, the parlour creels are worked in leaders of 50. Dalwhinnie also fishes a number of Gael Force creels.

Effectively starting with a clean sheet of paper, the owner and builders used their extensive experience of crabbing to develop a customised design in which particular emphasis has been placed on promoting optimum levels of crew safety, working efficiency and catch quality, in line with skipper Ian Mathieson’s favoured working patterns.

Backropes are flaked into a dedicated storage compartment set into the main deck under the hauler and receiving table.

Backropes are flaked down into a deck well from the hauler.

One hundred and thirty boxes of brown crab can be stored in Dalwhinnie’s chilled dry hold amidships.

On return to Stonehaven harbour, a telescopic deck crane, supplied by Penny Hydraulics and fitted forward on the port side of the main deck, is used to lift stacks of boxes out of the hold onto the deck, before they are lifted ashore by a flat-bed truck-mounted crane for delivery to The Crab Company (Scotland) Ltd at Peterhead.

A walk-in engineroom coaming is positioned aft on the starboard side of the main deck, while a full-width stainless steel-framed storage cradle is fitted across the transom stern.

Below main deck level, the hull is arranged from forward into a spacious galley, a three-berth accommodation cabin, the dry hold, the engineroom and the steering gear compartment.

The hydraulic tank and control valves are positioned either side of the return pipe on the forward bulkhead of the engineroom.

The well-equipped forward galley and the other internal accommodation areas on Dalwhinnie have been fitted out to an extremely high standard by Gerry Smyth’s experienced team, with light-coloured laminate panels and hardwood facings being used to give a simple yet stylish modern look.

Dalwhinnie uses a 1.5t Hydroslave slave unit for hauling her gear. Supplied by Irish agent KK Hydraulics of Tralee, Co Kerry, the 17in-diameter hauler is mounted on the starboard side of the forward wheelhouse, which is angled forward to ensure that the backrope leads as far forward as possible. Integral stainless steel rollers positioned just outboard of the hauler and at the foreside of the large-diameter gunwale roller – all of which were manufactured in-house by the yard – retain the backrope and guide the creels aboard.

The Doosan V158TI main engine…

Well-protected duplicate Kobelt engine and Furuno remote steering controls are mounted in a stainless steel box on the gunwale rail aft of the hauling position, enabling Dalwhinnie to be easily steamed up through the tide to the gear.

Pots are hauled onto an integral table for clearing and rebaiting, before being stacked three high down the port side, ready to be self-shot through the port side opening in the transom.

… is coupled to a Twin Disc 4.17:1 reduction gearbox.

On emptying the creels, undersized and white crab are returned to the seabed from the clearing table via an adjacent vertical pipe that leads down through the engineroom and out of the vessel’s hull.

Selected brown crab are placed into standard fish boxes, before being transferred to the dry hold when Dalwhinnie is heading to the next leader.

In order to keep the shellfish catches in optimum condition, the well-insulated and lined dry hold is fitted with a chilling system, in which a fan unit mounted on the deckhead can deliver the preferred ambient storage temperature of 6°C.

The refrigeration machinery for the chilling system, which was supplied and installed by Cool Temp of Kilkeel, is mounted on the forward bulkhead in the engineroom.

Pots stacked along the port side are self-shot through the offset transom gate.

The amount of thought that the skipper and builder put into the design and machinery layout of Dalwhinnie is probably best illustrated by the crabber’s impressive engineroom, in which the space available will give maximum ease of access for all levels of maintenance in years to come.

In addition to opting for an aft engineroom, accessed from a walk-in coaming on the main deck – which also houses a toilet compartment – skipper Ian Mathieson requested that the for’ard bulkhead be moved a frame further forward to maximise the already considerable space available.

Dalwhinnie is powered by a Doosan V158TI main engine derated to deliver 265kW @ 1,500rpm via a Twin Disc gearbox with a reduction ratio of 4.17:1 to a 1,370mm-diameter and 600mm-pitch propeller. Clements Engineering supplied the four-bladed propeller and sterngear. This combination of centreline machinery gave Dalwhinnie a top speed of 10 knots on sea trials from Kilkeel.

Dalwhinnie is based on a Buccaneer 46 hull moulded by Paul Ching of Roche.

Skipper Ian Mathieson is delighted with the low level of fuel consumption Dalwhinne is returning. This began with only around 1,700 litres of fuel being used when steaming the 700 miles from Co Down to Stonehaven, despite encountering some fairly poor weather during the first half up to Cape Wrath, after which conditions improved.

Two GRP wing tanks in the engineroom have a combined capacity of 5,500 litres. An additional 1,700 litres is housed in a third tank dedicated to the genset.

The vessel’s hydraulic system is directly driven from the fore end of the main engine through a Fenner coupling. SeaQuest Systems of Killybegs supplied the load-sensing pump and associated hydraulic equipment mounted on the forward bulkhead of the engineroom.

Cooling for the main engine is provided by two 3in-diameter stainless steel seawater systems, the intakes for which are placed on either side of the hull to minimise the risk of both being blocked simultaneously by an underwater plastic bag or other submerged flotsam.

Electrically operated pumps with changeover valves rather than hand-operated units are fitted for changing the main engine and gearbox oils – another measure designed to improve general operating efficiency.

Sea chests, valves and associated pipework on Dalwhinnie are protected from mussel growth by two Sonihull ultrasonic generators supplied by NRG Marine, to prevent the accumulations of mussels that can otherwise gradually reduce the supply of seawater going to a vessel’s cooling systems.

The Sonihull system works by producing bursts of ultrasonic energy in multiple frequencies, to create a pattern of alternating positive and negative pressure. Microscopic bubbles are created from the negative pressure, while the positive pressure implodes them, forming vapour cavities known as cavitation. The result of the implosion is a micro-jet action that creates a cleaning effect on the hull’s surface below the waterline. It also resonates and destroys single-cell organisms such as algae. Disrupting this first link in the food chain keeps the surface clean and makes it a much less inviting habitat for larger organisms that feed on algae.

A Sole Diesel 28kVA three-phase 415/3/50 genset housed in a soundproofed cabinet is mounted on top of the port wing tank.

Both the main engine and the genset will be serviced by Macduff Diesel, agent for both Doosan and Sole Diesel engines. In addition to supplying the main engine, Watermota also supplied the Doosan steering gear. This is fitted in the separate transom compartment, along with two Nilfisk pump units serving the duplicate power-wash systems supplied by Powerwasher Services of Laurencekirk.

The crew and vessel safety equipment came from Blue Anchor Fire and Safety Ltd of Fraserburgh.

A hydraulically driven Hardy bow thruster is fitted to give enhanced steering when Dalwhinnie is manoeuvring in restricted areas, such as the inner harbour at Stonehaven, where the crabber lies during poor weather, and when keeping station to the gear when the need arises due to unfavourable operating conditions.

Extensive Furuno integrated electronics package

Furuno UK supplied and installed an advanced package of integrated electronic equipment on Dalwhinnie, including a full software-based video switching system.

A second key feature is a dual 2D/3D TimeZero system giving a fully loaded professional fishing plotter integrated into the WASSP, radar and high-definition CHIRP sounder.

This arrangement enables each unit to be displayed using the TimeZero features along with their stand-alone capabilities i.e. using radar with chart overlay on TimeZero, using WASSP with the TimeZero chart/navigational system and using TimeZero to display information from the DFF1-UHD BB sounder.

Skipper Ian Mathieson had no hesitation in placing the order for Dalwhinnie’s wheelhouse electronics with Furuno UK, based on the high level of service support received since 2011 when the Fraserburgh company supplied the previous Dalwhinnie.

Having found a WASSP multibeam sounder invaluable in helping to locate and map suitable potting ground, the latest F3 model is again installed on the new Dalwhinnie. With wideband CHIRP technology, the WASSP scans a 120° swathe port to starboard using 224 beams and advanced signal processing to give a complete picture of seafloor bathymetry.

The wheelhouse electronics were supplied and installed by Furuno UK of Fraserburgh.

Output from the WASSP unit, together with that from the Furuno DFF1-UHD BB high-definition CHIRP BB sounder, is fully integrated into the dual 2D/3D TimeZero plotting system to provide optimum information on the profile and hardness of the seabed.

Other electronic equipment fitted on Dalwhinnie includes the overarching dual TimeZero Pro Fishing 2D/3D plotting system, Furuno DRS6A NXT digital radar, Furuno GP-33 GPS receiver, Furuno SC-70 satellite compass, Furuno Navpilot 711C autopilot system and Furuno FA-170 Class A AIS.

A Furuno FS-1575 MF/HF type-approved GMDSS radio telephone, Furuno FM-4800 GPS VHF C and Turbo Sailor Furuno Ka-band 2MB satellite system comprise the crabber’s communications system.

Furuno UK also supplied an eight-camera CCTV system which also incorporates an underwater hull-mounted camera focused on the propeller. This will provide skipper Ian Mathieson with invaluable visual information when stray ropes are near or in the fan, enabling him to make fully informed judgements.