Advantages of modern design of pelagic vessel clearly illustrated while engaging in traditional fishery

As Pathway thrust away from the Albert Quay into a rich sunset at the end of a hot summer’s day, the antiglare blinds in the wheelhouse immediately proved their worth, before skipper Georgie Buchan applied port helm to round the green pole, before crossing the bay to pass through the breakwaters, reports David Linkie

On passing the distinctive profile of Rattray Head lighthouse some two miles to port, the two-man watch was set as Pathway followed a plotter track towards a waypoint 15 miles east of Sumburgh Head, Shetland.

In the first week of July, Pathway’s skipper and crew were looking for their first shot of bigger herring for the fillet market.

For the previous five weeks, Pathway had fished maatjes herring, landing two small shots a week for a highly discerning market in the Netherlands, in conjunction with the well-known Dutch company Koelewijn Seafood BV. The lightly-brined raw fish is an eagerly-awaited local delicacy in Holland, where the sole specification for a fish known as a maatjesharing (maiden herring) is that it is required to have a fat content in excess of 18%, allied to the more subjective guidelines of a plump and deep-bellied body profile and rich stomach contents.

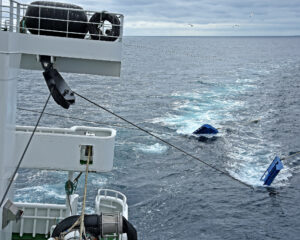

Starting to haul the wings of the Jackson Trawls 1,300m midwater net.

With the maatjes season and market drawing to a close at the end of the previous week, the focus was now on slightly larger fish, suitable for filleting.

Reports from boats fishing in a wide area stretching from the east side of Fair Isle and Shetland to the Norwegian sector over the weekend had not been particularly encouraging, with any marks that had been located generally being isolated and small.

This is thought to be attributable to the easterly wind set and low temperatures that prevailed in the opening months of the year and has subsequently meant a slow start to a number of fisheries in the North Sea, including prawns, brown crab and inshore mackerel.

Although better signs of herring coming together had been seen on Pathway’s previous trip east of Orkney, these were generally smaller, which, while making good maatjes, would not be so suitable for filleting requirements.

Two hours after starting to search east of Sumburgh, two or three small marks coming out of the bottom started to appear on the sonar before being tracked back to the boat. Although not considered worth calling the crew for, they at least provided an initial indication that it might be worth continuing to search in the area.

Apart from Cornelis Vrolijk some 10 miles to the north, the radar and AIS showed that most of the other freezer trawlers, including Maarte Theodora, Prins Bernhard, Annie Hillina, Sandettie, Carolien, Frank Bonefas and Jan Maria, were fishing around 60 miles into the northeast. A smallish fleet of Norwegian boats, some of which had already been on the grounds for 48 hours, were searching east of the line.

Antiglare screens show their value as Pathway leaves Peterhead.

Prospects weren’t too bright, but as skipper Georgie Buchan said: “If you stay on the park long enough, you will get a kick of the ball.”

With a slightly bigger mark occasionally appearing at 15 to 20-minute intervals, it was hoped that this might be the case, as the location of several marks were pinpointed on the fishing plotter.

The presence of gannets constantly circling low over the sea before swooping beneath the surface to feed gave further encouragement. This was confirmed by the Cornelis Vrolijk skipper, who reported steady fishing the previous night, when fishing marks high in the water with a custom-designed net and headline floats.

Although Pathway had detected a succession of similar high-standing marks, these were of little or no interest for the slightly misnamed midwater trawl, the chains of which are intended to lightly skim the bottom.

Searching some 12 miles east of Shetland, with the distinctive profile of Noss clearly visible to the north, Pathway was in an area that was a regular haunt for generations of drift-net crews, and subsequently those of the early purse-seiners from Shetland and NorthEast Scotland when fishing herring at a similar time of year.

On a morning when the cabinet secretary Michael Gove visited the new Peterhead fishmarket just 36 hours before the government published the fisheries white paper, it was a little strange to see that Pathway was the only Scottish boat engaged in a very traditional fishery. Having been in Portsoy 24 hours earlier for the Scottish Traditional Boat Festival, where two ex-sailing drifters were present, it also provided a reminder of how time and tide stand still for no man, and the continuing rapid rate of change the fishing industry continues to navigate.

Just over four hours after starting to look for marks, ‘make ready to shoot’ saw Pathway’s crew quickly don their oilskins, PFDs and hardhats before going onto the quarter.

Securing the tailend rope to the neck of the brailler.

At 10.30am, the bag was out-hauled and released as the 70m brailler ran out, before the 1,300m Jackson midwater herring trawl was shot off Pathway’s upper net drum along the single trawl deck. The dual-purpose herring and mackerel trawl is built with Jacinto twine in the mouth of the net and features eight-panel back ends. Consisting of polyethylene-covered nylon, Jacinto twine is reported to work well, shooting cleanly and quickly off the net drums.

A smooth shooting-away procedure carried out by a highly-experienced crew was suspended for a couple of minutes while the Simrad FS-70 trawl sonar transducer was secured in the headline pocket.

Within 15 minutes the double toe-end weights (2 x 1.1t) were clipped onto the footrope before being pulled aft along the dedicated tracks to fall clear of the stern. After crewmen working from the wrap-round boat deck across the stern connected the 100m sweeps to the Thyborøn Type 15 VF 14m² trawl doors, the surface area of which had been reduced to 12m² by opening some of the flaps, engineer Andrew Lemon started to release trawl wire from the split winches via the remote controls housed on the fishing console in Pathway’s wheelhouse.

After the trawl doors were initially held for a few seconds when some 30m from the stern, to check that the doors were swimming clear, they quickly submerged followed by 350m of Bridon 38mm-diameter Dyform Starfish wire, as Pathway started to tow the gear at 4.5 knots with 68% load on the Wärtsilä 9L32E2 main engine (5,220kW @ 750rpm) and 59% pitch on the 4,200mm-diameter CP propeller, which was turning at 130 revolutions per minute.

Towing in 57 fathoms of water, Pathway’s Karm 3010 autotrawl system was indicating a wire tension of 18t.

Twenty minutes later, Pathway’s Kaijo Ultra KCS-5221Z low-frequency (22kHz) sonar started to display the first echo 1,000m ahead, before being picked up by the KCH-3180 high-frequency (164kHz) sonar.

With total concentration and continual adjustments to the sonar range/tilt, propeller pitch and Simrad AP-80 autopilot, to ensure that the footrope chains were lightly skimming the bottom while maintaining an appropriate heading, skipper Georgie Buchan tracked the mark back to the boat when it appeared on the Simrad EK-80 split-beam dual-frequency (38kHz/200kHz) sounder displays.

Clipping on the toe-end weights.

With the mouth of the midwater trawl over 500m astern of Pathway and different current flows at varying water depths (displayed by a Kaijo KDG-300 tide machine), there is always a possibility of the fish slipping to one side of the gear in the 4-5 minutes that elapse between the boat passing over a mark and the fish coming to the doors.

After what, as usual, seemed an inexplicably long wait, the mark appeared on the Simrad FS-70 trawl sounder display. Though showing for only one sweep of the net sonar, the mark yielded sufficient fish (approx. 30t) to activate the first of five Scanmar catch sensors on the bag, after the fish were displayed entering the tunnel by a Scanmar Trawl Eye system.

A few minutes later another smaller mark of herring entered the net, after which the sonar display remained blank for the next 20 minutes. At this point, the decision was taken to heave the trawl doors back to the quarter, when Pathway came round to port before starting a reciprocal second leg of the tow back towards the area that had yielded fish and where a number of other smaller marks had been plotted earlier in the morning.

This decision was proved to be a correct one, when just over an hour later, during which time cook Frank Cordiner’s very tasty fish pie had been enjoyed by all, a succession of small but viable marks were shown in a successful sequence by Pathway’s sonars, hull and net sounder, resulting in a further two catch sensors being activated.

With no more marks coming to the boat, and eager to verify the size of fish in the net, Georgie Buchan made the decision to bring the near four-hour tow to a close, after which he could reassess his options if necessary.

Pathway comes round on the gear before starting the second leg of the first tow.

On engaging heave mode on the Karm autotrawl system, the Karmøy 90t split trawl winches quickly had the midwater trawl doors hanging at the gantry. This enabled the crew to clip on the G-links of the helper pennants, before the elevated aft 110t net drum started to wind on the sweeps and wings, after the toe-end weights were unclipped and stored in their deck racks. The brailler was dried up by the net drum before the tailend rope was attached and used to bring the lifter section to the port quarter, where it was taken aboard and clamped in position over the 18in inlet of the 24in SeaQuest fishpump, which is capable of delivering 10t per minute of fish to the CFlow fish/seawater separator.

As the Dyneema choker line tied just forward of the tailend splitter rings was pulled clear, the lifting hook of the Karm crane mounted atop the trawl gantry was clipped into a short becket before the fishpump was lowered into the water.

With the crane pulling the fishpump away to port, clear of the hull side, the splitter rope was slacked back as the tailend was lowered back into the sea. At the same time, the 20in-diameter fish hose and the hydraulic pipes that operate the fishpump were wound off the storage reels situated on the portside of the shelterdeck, directly below the fishpump on the boat deck.

Permanently connected to the pump, the fish hose lies in a deep vertical slot in the portside of the transom, allowing the hose to run clear of the stern as the pump is lowered into the water by the dedicated overhead crane. At the same time, the hydraulic pipes lead up from the reel and over a roller in an overhead opening in the boat deck, before following the pump through the slot now vacated by the fish hose.

After 60m of 5.5mm-walled fish hose were smoothly paid out from the reel, hydraulic oil started to be delivered to the pump motor, as the previously flat fish hose filled out as seawater started to be pumped aboard.

While adjusting the pressure of oil flowing to the pump at the same time as communicating by radio with the crewmen controlling the tailend winch and crane, Johnny Strachan quickly gave the thumbs up when herring started to flow past the transparent inspection window (the looking glass) incorporated into the first 1m section of the fixed delivery pipe directly above the pump controls.

By providing full vision of the rate at which fish are being pumped, the viewing section ensures that the relative positions of the pump, tailend and brailler, together with the optimum pump speed, rate of flow and mix of fish/seawater being pumped aboard can be adjusted continually during pumping to maintain maximum efficiency and delivery rates.

Heaving up the Thyborøn trawl doors.

A few seconds later, the first herring started to cascade down the forward section of the CFlow separator unit, having been delivered forward through a 35m run of 20in (600mm)-diameter stainless steel pipe.

Hydraulically-operated gate valves controlled the flow of fish towards the second tier of three RSW tanks that contained 250t of seawater, taken aboard 16 hours earlier shortly after Pathway left Peterhead and chilled from an ambient temperature of 10°C to -1.5°C during the night to be kept in optimum condition in a 1:1 fish/seawater ratio. This rate of cooling shows the capability of the two Johnson Controls ammonia-based refrigeration plants that each deliver 1,345kW of cooling per hour.

On entering the RSW tanks after being separated from the seawater, the fish immediately gain full benefit from the pre-chilled seawater. As soon as the fish are in the tank, the freezing is switched to full power to remove the latent heat from upwards of 100t of herring, in order to achieve optimum catch quality and, eventually, maximum fillet yield.

At the same time as the first herring were entering the storage tanks, some fish were delivered by a separate smaller pipe to the deckhouse amidships on the shelterdeck, where each fish was weighed on a set of Marel M2200 electronic scales. The initial computerised results printed off in the wheelhouse showed an average fish size of 165g. Although this was slightly less than anticipated, on a day when boats generally struggled for fish, skipper Georgie Buchan was fairly satisfied with the return from a tow in which the numbers for the average fish size would match the amount of 165t.

Starting to dry up the bag using the net drum.

Within 15 minutes of beginning to pump, the last herring slid down the delivery chutes. When the SeaQuest fishpump was lifted back aboard aft and the sock released, the remaining section of brailler was taken onto the net drum as the crew readied the trawl for the next shot.

Knowing that Lunar’s processing factories at Peterhead and Fraserburgh were hoping for fish the following morning, the decision was taken to look for further marks in the same area rather than steaming further off; a move which, if implemented, would effectively rule out the possibility of Pathway landing at Peterhead the next morning. Later in the week, this decision was shown to be the correct one, as after landing at Peterhead the following morning, Pathway returned to sea 12 hours later, before fishing 20 miles further into the northeast on Wednesday, for 500t of 225g herring.

An hour later, a series of small marks led to the call to stand by, at the same time as Brazil was on the point of eliminating Mexico from the World Cup.

After some initial activity when towing into the west, further marks proved elusive, so for the second time in six hours, the doors were hauled to the surface before Pathway again came round on the gear, this time to starboard.

With the gear all square again and a door spread of 160m, 40 minutes of inactivity were ended when a small mark passed under the boat before an angle swipe of the net sonar showed fish entering the net.

As is frequently the case, the limited signs of life that had been shown on the underwater acoustic displays earlier in the day, had all but disappeared, as the screens in the wheelhouse remained blank.

Not long after Belgium had recovered from being two goals down to Japan to win 3-2 in the last minute, two marks were picked up by the low-frequency sonar before some more fish entered the net, as the second catch sensor turned green.

By now with one eye on the time for returning to Peterhead shortly after breakfast time the following morning, the doors were quickly brought back to the gantry before the sweeps were hauled onto the drum.

The last flush of herring cascade down the separator after the restrictor is removed in the bag.

What proved to be a 75t haul was soon disappearing into the RSW tanks, but not before it gave the opportunity to take the photographs missed the first time round, in order to complete a full sequence.

Shortly after 10pm, when the crew were washing down the decks and the e-log was being sent, Pathway got underway for Peterhead 130 miles to the south.

Going alongside at 8.30am, when fishery officers were waiting to dip the tanks, the first of 240t of prime-quality North Sea herring started to be discharged directly into the quayside factory and waiting road tankers for delivery to Lunar’s processing facility at Fraserburgh.

While the new Pathway (and her sistership Kings Cross) clearly represent significant levels of reinvestment, as well as commitment and confidence in the long-term future of the pelagic sector from a catching perspective, this is only one part of a complex chain.

Modern processing facilities capable of delivering premium products in line with customers’ increasingly high-end requirements in a highly competitive global market, are of equal importance to modern vessels. After putting on the requisite protective clothing before entering Lunar’s Peterhead factory, the level of investment in the state-of-the-art gleaming stainless steel processing lines, was immediately apparent.

Herring fishing today, both in terms of vessels and processing, has come an extremely long way since the days of drifters and gutting/salting stations on the quays. However, these totally different eras share one vital factor, the natural resource. The present-day North Sea herring stock, like mackerel, holds MSC certification for being a sustainable and well-managed fishery.

Healthy and reliable stocks are an incredibly valuable resource that gives all stakeholders, including buyers around the world, the confidence required to invest in the long-term future for the mutual benefit of all. At a time of potentially far-reaching changes, it is vitally important that an extremely advantageous starting position, and what the industry has achieved and continues to deliver, is fully recognised at all times.

Thanks to the skipper and crew of Pathway for making this feature possible at short notice.

Pumping over the stern brings major advantages

The skipper and crew spoke highly of the level of performance Pathway PD 165 has returned since being delivered by Karstensens Shipyard in May 2017, seven months after her sistership Kings Cross PD 365 was completed at Skagen.

As anticipated at the time Pathway was ordered, one of the main benefits the vessel is now delivering is the enhanced levels of fishing efficiency and safety associated with pumping trawl-caught pelagic fish at the stern, which in recent years has become an increasingly common feature of new pelagic vessels.

Starting to lift out the fishpump with the sock attached.

One of the main advantages of pumping at the stern is that by eliminating the need to take the bag forward when the vessel lies broadside on to the weather, hauling the bag becomes a continual process, with the added bonus of the vessel not having to change course.

While using the net drum to dry up the brailler, the 57t tailend winch mounted to port on the upper boat deck is used to haul the back to the quarter, before the sock is attached to the pump located on the main boat deck just forward of the trawl gantry.

The time saved by eliminating the need to take the bag forward, when the crew are working in considerably more challenging conditions in heavy seas, is appreciable. The savings in time are particularly noticeable when handling relatively smaller shots of fish, as was the case on this trip.

With pumping lasting less than 15 minutes, the brailler was back on the net drum and outhauled ready to shoot again, in around the same time it would have taken to start pumping amidships on the previous Pathway.

The new arrangement was also reported to perform well when dealing with bigger hauls of mackerel and blue whiting in poor weather, when running before the swell.