The skippers and crew of Guiding Light H 90 quickly started to establish the fishing credentials of the new whitefish vessel by landing a 1,290-box maiden trip at Peterhead last week, after pair-seining with Guiding Star H 360 on the Fair Isle grounds, reports David Linkie

In keeping with the longstanding tradition, the first box of fish landed by the new boat, a box of cod, raised £700 for charity when bought by Caley Fisheries. Guiding Light’s crew immediated donated this generous total to three local charities, the Fishermen’s Mission, RNLI and Peterhead Fishermen’s Benevolent Fund, of which skipper Gavin Thain is vice-chairman.

The 26m Guiding Light represents another significant achievement for two Yorkshire companies. The vessel was built by Parkol Marine Engineering for the Hull fishing company Andrew Marr International Ltd, and is a sistership to Guiding Star H 360, which the Whitby boatyard completed in 2014.

Apart from a few very minor differences to working arrangements and internal layout, as is inevitable between new boats, Guiding Light – the starboard boat in the new pair team – is a virtual mirror image of Guiding Star. This underlines the consistently successful level of performance, in terms of fishing efficiency, seakeeping qualities and fuel economy, that Guiding Star has delivered since entering service four years ago, which clearly gave the owners the confidence to place an order for the second half of an identical pair team.

Each boat features the latest hi-tech combined Scantrol and Scanmar systems. Supplied and installed by Scanmar UK of Peterhead, these integrated arrangements use information from the Scanmar ScanMate 6 net-monitoring and symmetry sensors to enable the Scantrol iSYM autotrawl system to adjust wire lengths to maintain optimum net shape.

The wheelhouse electronics were supplied by Furuno UK, Scanmar UK and Woodsons.

Scantrol PairLink systems ensure that the pair teams gain maximum operational benefit from these hi-tech systems. The automated functions allow the nominated master vessel to control the second slave boat when towing, including course heading, navigation, separation distance, engine speed and adjusting warp length to maintain net symmetry.

Having sailed as relief skipper to Bobby Smith on Guiding Star, Gavin Thain was able to put this experience, and a lifetime’s knowledge, to good use when liaising closely with the Parkol team during the build and fit-out of Guiding Light.

Gavin Thain spent considerable time at Whitby when Guiding Light was being fitted out, and views this as an important factor in the end result. “Being onboard and working alongside the boatbuilders meant that decisions, often on small points, which all contribute to the bigger picture, could be taken there and then. The Parkol team were always fully receptive to suggestions and ensured that they were incorporated in the end result, which to me, speaks for itself.”

Gavin Thain and Barry Fenty will skipper Guiding Light, the crew of which consists of Ronald Beagrie, James Butters (cook), Barry Fenty and Joe Weyness. Wheelhouse duties on Guiding Star will be shared by Bobby Smith, who has been skipper since the boat was new, and Richard Watson. The pair team is expected to work six- or seven-day trips, before landing into Peterhead, where the boats will work through P&J Johnstone Ltd.

Designed by Ian Paton of SC McAllister & Co Ltd, Guiding Light has main dimensions of LOA 26m, registered length 23.98m, beam 7.8m and depth 4.3m. Although sharing the same main dimensions as Guiding Star, the new boat’s round bilge hull incorporates a number of ‘little tweaks’ designed to give optimum levels of performance.

These include slightly fuller hull sections aft, and raising the shelterdeck slightly.

Particular consideration was given to the bow and underwater stern sections, from the differing perspectives of combining maximum deck space forward, load-carrying, and vessel trim throughout a trip, with propulsion efficiency and seakeeping qualities. The result is a full bulbous bow and fine waterline entry, above which there is a considerably concave raked stem and strongly flared bow section, to ensure that the vessel’s not-inconsiderable 7.8m beam is carried well forward, while the aft lines sweep up to the transom.

Forward, the flared bow shell plating blends stylishly into the traditional tumblehome shelter sides at the sweeping sheerline rail that is a key visual signature of this design of vessel.

Once the hull design was finalised, Deri Jones Associates generated the cutting information, which was then transferred to Holland for cutting and forming of the double-curvature shell plating, before this was delivered in stages to Whitby.

Guiding Light features a fairly conventional arrangement, with a watertight full-width deckhouse separating the forward catch-handling area from the net-handling area on the quarter. The non-watertight deckshelter is constructed with steel from the deckhouse aft to the transom, and with aluminium alloy forward. Below main deck level, the layout from forward follows the norm of forepeak and chain locker, fishroom, engineroom and accommodation cabin.

The hard bottom and semi-clean pair-seines came from Jackson Trawls.

The fore and aft connecting passageway in the deckcasing, which also provides heated oilskin storage, is offset to the starboard rail.

The spacious and well-equipped galley and messdeck, in which two mess tables are accommodated, extends the full length of the deckcasing on the port side. An ensuite skipper’s cabin is centrally located in the deckhouse, along with a shower/toilet compartment on the aft side of the passageway leading to the wheelhouse and main accommodation cabin. Down the aft stair, eight bunks are provided in four similar-sized cabins, arranged forward and aft of each other along either side of the hull.

The internal accommodation areas on Guiding Light are finished to the customary high standard that in recent years has almost become taken for granted. Natural-coloured oak laminates and timber facings are used in the wheelhouse and cabins, while a combination of cream and white contribute to the spacious appearance of the galley and messdeck.

Rapp Ecosse Ltd of Peterhead supplied Guiding Light’s full deck machinery package and designed the vessel’s load-sensing hydraulic system, the installation of which was completed in-house by Parkol, with stainless steel being used throughout.

A single pair-seine winch, custom-designed to give maximum shooting and hauling speeds, is centrally positioned on the foredeck. The large-capacity two-speed winch has a first layer pull-rating of 21.6t and, depending on which drive step is being used and the amount of wire/rope on the drum, delivers hauling speeds of between 41 and 416m/min. When shooting away the gear, warps can be run off the drum at 98-497m/min.

Rapp Marine also manufactured and installed an identical new winch on Guiding Star, to ensure that the pair team replicate the same level of performance when shooting and hauling some 700 fathoms of warp.

From the winch, the warp is guided through a wide funnel, fitted with rollers, mounted on the underside of the shelterdeck, to lead along the vessel’s centreline under the wheelhouse to a sheave on the shelterdeck, from where it is inclined upwards to a central hanging block. Manufactured by Flemings Fairleads, the block is mounted on a triangular outrigger extending from the full-width stern gantry to overhang the transom rail.

Two 2 x 12.2t split net drums are arranged side by side on the hardwood-planked quarter, which is left open across the transom. Two free-turning rollers are fitted atop the transom rail either side of central strong backs, to assist in handling the heavy ground gear. The higher-than-usual transom rail is designed to give maximum protection when hauling the gear in heavy weather.

A third net drum, manufactured by Rapp Ecosse to the same performance specification, is mounted on the starboard side of the shelterdeck. This upper net drum is primarily intended for use in the event of single enders, when the net and the warps will be hauled onto the usually spare drum.

A 9.2t messenger winch, mounted atop the shelterdeck to port abaft the wheelhouse, in line with a captive roller forward of the trawl gantry, is used to haul across the end after it is released when the boats come together to click out.

A Rapp Ecosse 13mt short-post kinked-boom power-block crane, with a reach of 7.1m to a Rapp 24RA wide power block, is mounted on the centreline of the trawl gantry, to assist with outhauling the trawls and drying up the bags.

The codends are taken aboard forward on the starboard side by a dedicated 9.3t Gilson winch, serving a square-framed lifting gantry arranged over a hydraulically-operated hatch and a large reception hopper, capable of holding over 200 boxes of whitefish.

A separate 2t anchor windlass, with chain lifter and warping head, is also fitted for anchoring duties.

The QuikSling apparatus is housed in an easy-access cabinet on top of the shelterdeck.

A QuikSling MOB recovery system is housed in a cabinet strategically positioned aft of the wheelhouse on the shelterdeck. Its presence, together with that of two 10-man liferafts and 10 survival suits, highlights the careful consideration skipper Gavin Thain and the owners have given to crew safety.

Seagate Fabrication of Peterhead supplied the fully-integrated and basketless aluminum and stainless steel fish-handling system, which has been designed to enhance catch quality while reducing the crew’s workload. A transverse conveyor lifts fish from the base of the hopper and across the full beam of the vessel. After being gutted, fish are placed in one of the 11 elevated section hoppers available. A second conveyor, positioned to the portside of the main fishroom hatch, is used to take fish from three separate washers forward for delivery via chute to a selection table in the fishroom, for weighing and boxing.

A KM gutting machine is situated to port to accelerate the handling of smaller fish. Fish selected for machine gutting are placed into a large stainless steel hopper, the false bottom of which can be raised hydraulically to minimise the amount of bending required by the crewman feeding fish in. After gutting, fish drop into a dedicated washer, from which they are directed back onto the conveyor for delivery to a stainless steel section hopper in the fishroom. All selections of fish are weighed, using a set of Marel electronic scales located in a stainless steel-sheathed section of the fishroom to starboard, before labels are printed off by a VCU catch management system, from which all data is sent automatically to a computer in the wheelhouse.

With 169 stackers supplied by Box Pool Solutions in each of the first four tiers, the fishroom on Guiding Light has a working capacity of some 1,200 boxes.

In addition, 12t of flake ice, supplied by three Geneglace 2.5t ice machines housed in dedicated compartments situated on either side of the main deck forward of the fishroom hatch, can be stored in full-height stainless steel-lined lockers arranged across the fore end of the fishroom.

Nordkøl ApS of Hanstholm supplied the ice machines, in addition to fitting the stainless steel refrigeration pipes mounted on the fishroom deckhead.

When landing, 12 boxes are swung ashore together, using a Rapp Ecosse RLC8 short-post 8mt stiff-boom landing crane, mounted forward on the portside of the shelterdeck and fitted with a 2t landing winch. A Pullmaster winch is used to pull stacks of boxes forward to the hatch when landing.

The engineroom on Guiding Light is particularly spacious, with a well-thought-out arrangement giving driver Joe Weyness ease of access for all levels of service in the future.

Guiding Light’s Mitsubishi main engine, together with the two auxiliaries, were supplied and commissioned by Padmos of Stellendam. This further consolidates the working relationship that Parkol has developed with the Netherlands company in recent years.

The Mitsubishi S6R2-T2MPTK main engine develops 480kW @ 1350rpm, and is coupled to a Reintjes WAF 474 7.476:1 reduction gearbox. This combination results in the 2,500mm-diameter four-bladed fixed-pitch propeller turning in a customised nozzle, fabricated by Parkol, at a maximum speed of 180rpm, and one of around 140rpm when typically towing with the main engine running at 1050rpm.

The Mitsubishi S6R2 main engine develops 480kW @ 1350rpm, and can drive a duplicate load-sensing hydraulic system through a Twin Disc clutch mounted at the fore end.

Together with the hull design, this combination of centreline machinery gave Guiding Light an average top speed of 10 knots on engine trials off Whitby.

A Mitsubishi S6B3 auxiliary engine (335kW @ 1500rpm) mounted on the port tank top powers the main deck machinery hydraulics through a Twin Disc clutch driving two variable displacement Kawasaki load-sensing pumps when hauling and shooting.

A similar system, mounted at the fore end of the main engine, provides a duplicate load-sensing hydraulic drive arrangement with the capability to replicate the performance of the main system, in the unlikely event of auxiliary engine failure mid-trip.

When the hydraulic engine is switched off during fishing, the autotrawl system for pair-seining is operated by a 30kW electrically-driven load-sensing pump.

Electrical supplies onboard Guiding Light are delivered by 240kVA Newage Stamford 415/3/50 generators, driven by both the hydraulic auxiliary engine and a Mitsubishi 6D24 auxiliary engine (175kW @ 1500rpm).

A 100-amp output Victron 24-volt charger is also fitted in the engineroom, ensuring that all engine batteries have two methods of charging: either from the engine alternator, or from the Victron unit.

Pearson Electrical of Hull was subcontracted by Parkol Marine Engineering to undertake the electrical installation work on Guiding Light alongside the boatyard’s own electricians.

Touch-screen units provide comprehensive coverage of all the bilge, fuel and freshwater tanks throughout the vessel.

Strategically located close to the main navigation position, the advanced system enables the crewman on watch to easily monitor vessel safety at all times.

In the unlikely event of a bilge pump failure, the system is automatically activated via the relevant high-level bilge alarm, even if all is normal in the associated compartment.

Provision has also been made for the vessel management system to be accessed from a nominated iPad via WiFi, and for warning texts to be sent to a selected mobile.

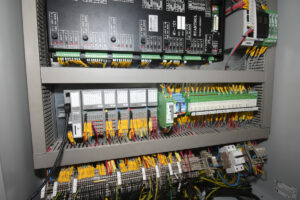

The nerve centre of the Scantrol iSYM automated pair-seine system.

NRF box coolers, arranged across the forward end of the engineroom, provide cooling for the main and two auxiliary engines, together with the hydraulics.

In order to prevent the spiral tubing found inside box coolers from becoming encrusted with barnacles and mussels, which impair the transfer of heat, Guiding Light is fitted with a Cathelco Marine Growth Prevention System (MGPS).

Supplied by Cathelco Grampian of Aberdeen, the MGPS incorporates a copper anode directly beneath the cooling tubes in the seachest. A steel cathode plate, running parallel to the anode, ensures an even distribution of copper ions, which prevent marine organisms from settling and growing. As the concentration of copper is less than two parts per billion, there is no risk to the wider marine environment in which the vessel is operating.

Cathelco MGPSs are widely used to protect the seawater pipework systems of fishing craft against blockages caused by bio-fouling. A range of anodes has been developed which can be installed in box coolers, seachests or strainers, and wired to a compact control panel.

A hydraulically-powered Kort KT 250 bow thruster of 186kW is fitted, to give maximum vessel manoeuvrability in restricted areas.

Fuel capacity is 24,000 litres, housed in a combination of engineroom wing tanks and two double bottom tanks under the concrete floor of the fishroom, and 26,000 litres of freshwater is carried in bulbous bow and double bottom tanks.

One of the key characteristics of Guiding Light is the vessel’s ability to return to harbour with the white line still sitting above the water forward, when carrying some 55t of fish. Retaining the optimum fore and aft design trim throughout a trip further enhances propulsion efficiency, fuel economy and vessel safety.