Karstensens Shipyard delivers second pelagic vessel to Peterhead.

Skipper Georgie Buchan, and the crew of the new pelagic vessel Pathway PD 165, started fishing maatjes herring in the North Sea within a week of berthing the dual-purpose 78.75m midwater trawler/purse seiner in Peterhead for the first time, reports David Linkie.

Above: The 78.75m purse-seiner/midwater trawler Pathway leaving Peterhead for the first time.

Designed and built by Karstensens Shipyard for Lunar Fishing Ltd of Peterhead, Pathway completes a notable Peterhead double for the prominent Danish yard, as the vessel is a sistership to Kings Cross PD 365, which started fishing towards the end of October 2016.

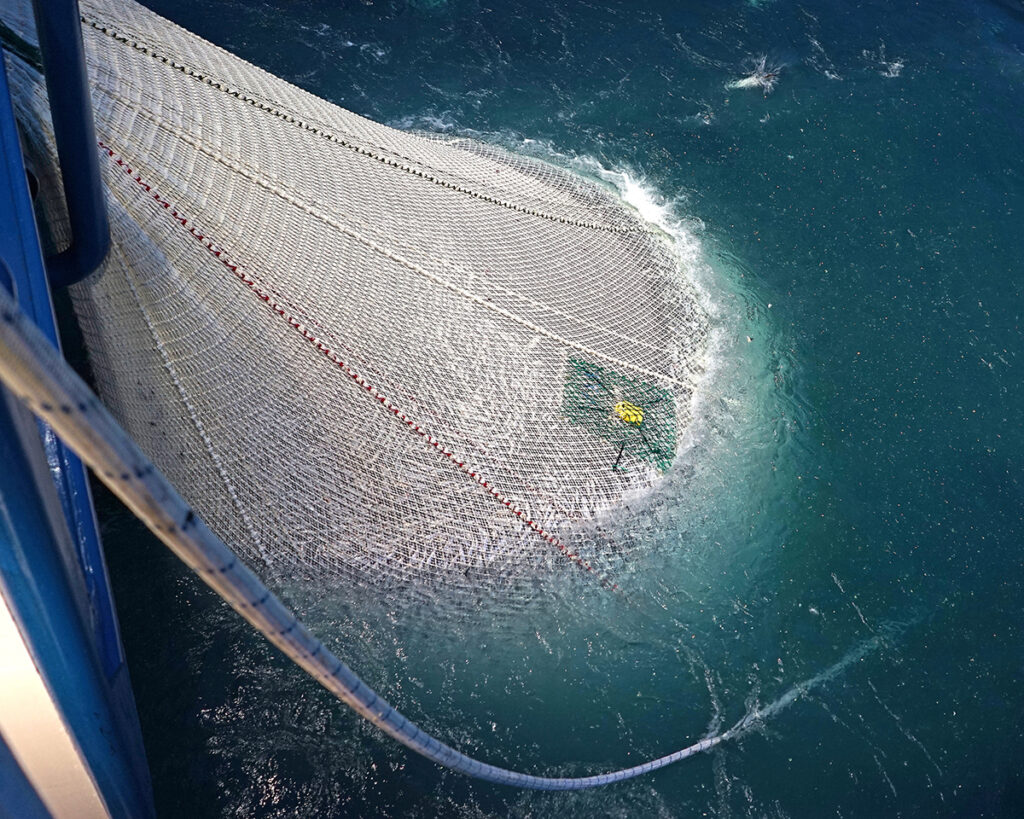

Drying up Pathway’s first bag of maatjes herring taken in a Jackson Trawls 1,300m midwater net in preparation for pumping over the stern. (Photo: Andrew Ritchie)

Built to replace the 66.6m Pathway, which was sold to Russian owners 15 months ago, the new Pathway is representative of the next generation of midwater vessels, of which a number are at various stages of design and build for well-established partnerships in northeast Scotland, N Ireland and Shetland.

The high level of specification of these new pelagic vessels, which incorporate full-length boat decks giving optimum levels of safety for the crew, in addition to advanced fish pumping and storage systems design to deliver optimum quality catches, is also shown by the fact that Pathway has a top speed of over 18 knots, and can steam at 12 knots when running in dedicated electric propulsion mode.

Pathway is equipped for both midwater trawling and purse-seining, with the capability to alternate between these contrasting fishing methods quickly and efficiently during a trip. This characteristic gives access to the often considerably higher prices offered for pursed mackerel in a highly discerning and competitive global market, usually taken at the beginning of the autumn North Sea fishery, when a high proportional of Norwegian and Danish pelagic vessels continue to use purse seines in preference to midwater trawls.

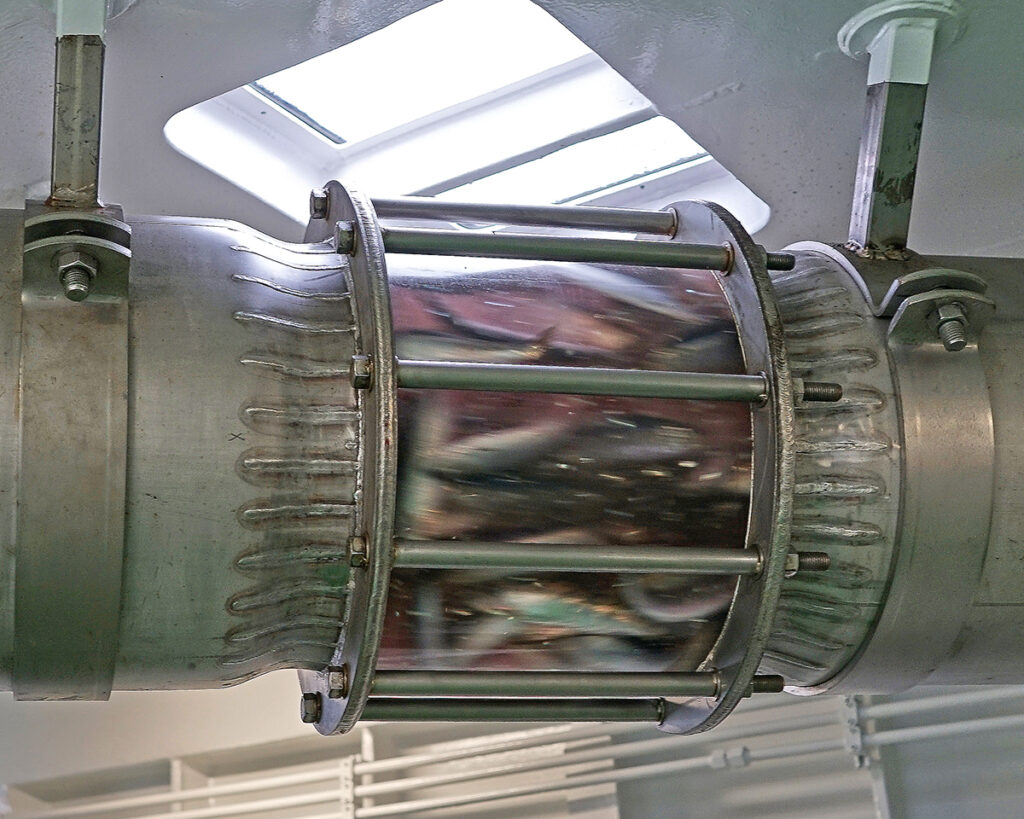

Large-diameter stainless steel pipes deliver pelagic fish from the CFlow separator unit into the selected RSW tanks.

Achieving the desired degree of flexibility between pursing and trawling should not be underestimated, but the owners used their experience of combining these methods in recent years to good effect, to ensure maximum levels of efficiency and safety on Pathway, which, like Kings Cross, is equipped with a Karm Tristar Giant net hauler – the most powerful of its type in the world.

With the owners moving to pumping trawled fish aboard at the stern, Pathway is equipped with two separate fish pumping systems, highlighting the fact that pursed fish is taken aboard amidships on the starboard side after the bunt is dried up.

Given the large qualities of sustainably-accredited pelagic fish caught in UK waters each year, that Pathway will be followed by another eight state-of-the-art midwater boats scheduled to replace older vessels in the next two years, is highly significant, particularly at a time when the long-term impact of Brexit continues to be discussed.

Pathway United FC team lineup.

Back row left-right – Skipper Georgie Buchan, Sandy Florence, George Jack, John George Buchan, Andrew Lemon, Andrew Ritchie and Frank Cordiner.

Front row – John Leonard, Andrew Richie, Benny Noble, Simon Stephen and Aaron Anderson.

After Karstensens Shipyard handed Pathway over to the owners in Skagen towards the end of May, the vessel was quickly off the blocks to prove its initial capabilities fishing maatjes herring in the vicinity of the Frigg Field, some 120 miles northeast of Peterhead. In the first three weeks, Pathway completed five short trips when landing small shots in line with processing capacity and market opportunities in the Netherlands.

After the third landing, during which the vessel’s trawling, fish pumping and RSW storage systems worked smoothly from the word, skipper Georgie Buchan said: “We are extremely happy with how Pathway is performing, as well as the level of build quality and finish throughout the boat.

Karstensens, together with the other suppliers, have delivered in full and done us proud. We are looking forward to the challenge of proving the vessel’s capabilities in years to come.”

General arrangement

Designed in-house by Karstensens Shipyard in close liaison with the owners, the vessel’s round bilge hull, which has a beam of 15.5m and a depth to shelter deck of 9.2m, was built to Det Norske Veritas, +1A1 Fishing Vessel, hull: Ice-C class by Nauta Shipyard in Gdansk, before being towed to Skagen in July for machinery installation and fitting-out.

The long forecastle and aft wrap-round boat decks are joined by wide side decks amidships, to effectively create a full-length boatdeck that gives the vessel a streamlined profile.

General view of Pathway’s wheelhouse.

Having previously been fully satisfied with the benefits associated with internal corridors at main deck level either side of the RSW tanks, together with separate vacuum discharge and RSW machinery rooms, the owners opted for similar arrangements on Pathway.

As a result, the hull below the main deck is subdivided into forepeak, bow thruster/sonar room, RSW pump and manifold room, insulated RSW-tank section, engine room and aftpeak with fuel and lube oil tanks.

At main deck level, the arrangements from forward are forepeak, RSW machinery room, forward RSW trunk section, central vacuum landing room and the two aft-most tiers of RSW tanks. Aft of these working arrangements, a combination of eight single and twin-berth ensuite cabins lie to starboard of the vessel’s centreline. The engine control room is positioned on the portside, forward of a well-equipped workshop and the hydraulic pump room. A fitness gym is also arranged aft on the starboard side, equipped with exercise bike and running machine.

A Karm Tristar Giant purse net hauler is mounted on the full-length boatdeck between the purse gallows and the net chute.

A further four single-berth cabins and the hospital cabin, which includes a bath, are located in the full width superstructure at shelterdeck level, together with protective clothing storage, changing room, coffee bar, large trawl workshop and a fishing sensor charging room.

Cook Frank Cordiner’s well-equipped stainless steel galley is positioned to starboard in the accommodation structure at boat deck level, together with separate walk in dry-provision, fridge/freezer rooms, aft of the messdeck where a large oval table and heated food self-serve arrangements are key features.

An open-plan spacious day lounge is arranged to port, forward of a second smaller glass-enclosed TV room.

Four further ensuite skipper cabins, together with a walk-in room housing the array of computers for the vessel’s electronic equipment, are located on the next deck up under the wheelhouse.

Pathway features an exceptionally high level of internal finish throughout the accommodation areas, which really have to be seen to be fully appreciated. Light coloured, natural wood, planked flooring underpins an understated modern look, which is further enhanced by a combination of prints illustrating the rich heritage of herring fishing, together with atmospheric photographs taken on the previous Pathway by mate Andrew Ritchie.

The extensive use of solid walnut, beautifully crafted and finished in-house by Karstensens, is a key feature of the internal finish.

Purse-seining

The purse-net bin is situated aft on the starboard side and extends down to the shelterdeck. In keeping with modern practice, the net is shot away through a rectangular opening between the main boat deck and the raised second boat deck that extends aft from the front of the accommodation casing. The large-radiused outer top edge of the net bin is constructed from stainless steel to minimise rubbing.

Happy at their work – John George Buchan Jr and George Jack, splicing sweeps in preparation for Pathway’s first trip.

Two 40t purse winches are mounted forward of the RSW tank tops on the shelterdeck. The starboard winch is aligned to lead the 34mm-diameter Dyform wire aft to a hanging block and the pursing needle, while the port winch has a direct lead across the beam to a second block on the forward gallows. A 20t end wire winch is located on the boatdeck forward of the deck casing.

Supplied by Mørenot AS, Norway, Pathway’s 430 fathom x 117-fathom purse net will be hauled by a Karm Tristar Giant net hauler. When the purse has passed through the triple rollers, the net is pulled through a large-diameter stainless steel shoot by an intermediate roller, from where it is hauled further aft by a Karmoy net stacker and a Triplex float stacker, before being stowed in the bin ready for the next purse.

Karmøy also supplied four remote-controlled deck cranes that provide invaluable assistance when handling the midwater nets and pumping fish. In addition to the folding netstacker unit that includes a 4t roller and 5t winch on a 13m reach positioned between the purse bin and the trawl deck, a 5t/10m knuckle arm pump for handling the aft fish pump is mounted on the trawl gantry directly over the port support leg for maximum strength.

A 4t/18m gooseneck style crane covers general handling duties amidships, where a fourth Karmøy crane is also located to handle the purse net fish pump.

Fish pumping

Trawled catches of blue whiting, herring and mackerel will be taken aboard aft on the portside of Pathway, using one of two 24in fishpumps manufactured in Killybegs by SeaQuest Systems. A similar pump, delivering high levels of catch quality and pumping capacity, that SeaQuest supplied to the previous Pathway at extremely short notice led to two identical units being delivered to Kings Cross last year and now to the new Pathway.

Two Caterpillar C18 gensets, delivering 550kWe each, are located in a sound-proofed room within the engineroom.

Pumping pelagic fish at the stern is a first for the skipper and crew of Pathway (apart from their trips on Kings Cross during the mackerel and blue whiting seasons earlier this year), and one that they are looking forward to, due to the increased efficiency and crew safety provided by this arrangement, which is now becoming a common feature of new pelagic vessels.

One of the main advantages of pumping at the stern is that by eliminating the need to take the bag forward when the vessel lies broadside on to the weather, hauling the bag becomes a continual process, with the added bonus of the vessel not having to change course. While using the net drum to dry up the brailler, the 57t tailend winch mounted to port on the upper boat deck is used to haul the back to the quarter, before the sock is attached to the pump located on the main boat deck just forward on the trawl gantry.

The large-diameter reels, on which the fish hose and hydraulic pipes are stored, are situated on the portside of the shelterdeck, directly under the fish pump. The fish hose – permanently connected to the pump – lies in a deep vertical slot in the portside of the transom, allowing the hose to run clear of the stern as the pump is lowered into the water by the dedicated overhead crane.

Fish pumping and vacuum discharge operations are controlled from touch-screens in the deckhouse.

At the same time, the hydraulic pipes lead up from the reel and over a roller in an overhead opening in the boatdeck, before following the pump through the slot now vacated by the fish hose.

A short, clear Perspex section of pipe (the looking glass) enables the crewman controlling pumping operations to constantly monitor the flow of fish. The large-diameter stainless steel pipe extends some 35m forward on the portside of Pathway on the underside of the boat deck, before turning inboard towards the CFlow fish/seawater separator system mounted within the forecastle deck forward amidships.

Further evidence of the high level of build quality found throughout Pathway is provided by the fact that the pipe is fully enclosed along the sidedeck. This attention to detail is further highlighted by the extensive double skin plating on the sides of the hull and the underside of the decks, which, by providing a flush surface rather than numerous frames, will make the boat considerably easier to keep clean in years to come.

Two MMC 4,200-litre vacuum discharge tanks are served by 4 x 66kW compressors located amidships on the main deck between the middle two tiers of RSW tanks.

When purse-seining, usually at the start of the autumn fishery in the North Sea, mackerel will be pumped aboard slightly forward of amidships on the starboard side, with the associated equipment located on the boat deck. The fish hose reel is mounted on a hydraulically-operated slide, so that it can be moved out to the side of the vessel before pumping starts, to ensure maximum operational efficiency.

Catch storage

When pumping, the flow of pelagic fish from the separator into the 12 RSW tanks is remotely controlled from a dedicated pump room located within the centre deckhouse, which also contains a dedicated sampling room.

On entering the water separator, fish are directed upwards before sliding either forward or aft into transverse troughs, from where they are directed to the allocated RSW tank by remotely-operated vertical gate valves.

Maatjes herring flowing through the clear section of delivery pipe. (Photo: Andrew Ritchie)

Twelve stainless steel pipes, rather than the traditional arrangement of chutes, are used to deliver fish directly into the selected RSW tank. One advantage of this modern system is that it leaves the tank hatches clear for the engineer to easily check the level of fish visually, without the need to move the delivery chute aside.

Arranged in four banks of three, the 12 RSW tanks on Pathway have an internal volume of 2,500m³. This ensures that optimum levels of catch quality will be delivered on each trip, with the vessel’s skippers and engineers having maximum flexibility in selecting the ratio of fish to seawater at all times.

With buyers worldwide requiring ever-higher standards of catch quality, the owners have put a strong emphasis on landing a top-quality product by being able to reduce the temperature of pelagic fish entering the RSW tanks down to an optimum storage temperature of between 0°C and 1°C as quickly as possible. Two ammonia-based refrigeration plants supplied by Johnson Controls deliver 2.3mKcal/h of cooling capacity, enabling pelagic catches to be brought down to the desired level in often less than two hours, depending on the quantity of fish pumped aboard and the number of RSW tanks brought into use.

Pelagic catches from Kings Cross are discharged to processing factories ashore by a twin MMC 4,200-litre vacuum pumping system. Using 4 x 66kW vacuum power packs, the system has a discharging capacity of up to 2 x 150t per hour.

The distribution of pelagic fish into the RSW tanks through tank sounding, pump and valve control when pumping is just one of the functions performed by a Johnson Controls-developed and delivered monitoring system installed on Pathway. In addition, a similar system was supplied by Norwegian company MCS. This system which is extremely and easy to use, monitors all aspects of onboard management, including the performance of the main and auxiliary engines, electrical supply and distribution, alarms, fuel/oil capacities and transfer, ballasting and electrical loading.

Engineroom

Pathway is the third new Scottish midwater vessel delivered in the past eight months to feature a diesel/electric propulsion system.

The Wärtsilä 9L32E2 propulsion unit (5,220kW at 750rpm) drives a Wärtsilä 4,200mm-diameter four-bladed CP propeller system housed in a high performance fixed nozzle through a matching Wärtsilä SCV 112/2 PDC70 two-speed 6.043:1 reduction gearbox. This gives two fixed propeller speed steps of 125rpm and 90rpm.

A PTO on the gearbox drives a Marelli 2,500kWe shaft generator.

Auxiliary electrical power on Pathway is provided by three Caterpillar C18 gensets delivering 550kWe each. Two of the C18 gensets, together with a Caterpillar C6.6 harbour genset of 150kWe, are housed in a sound-proofed compartment on the port side in the engineroom. The third C18 genset is located at shelterdeck level in the forecastle.

When Pathway is hauling and shooting the fishing gear, the gearbox PTO will be clutched in, enabling electric power for the electro-hydraulic motors to be supplied from the shaft alternator. This arrangement reflects the fact that when full power is required for the deck machinery, there will normally not be the same demand for power on the main engine, allowing it to meet requirements for both the propulsion and hydraulic systems.

Pathway PD 165

During normal towing, the shaft alternator can be disengaged from the switchboard, when electrical power is supplied by either of the gensets, through the main switchboard and controlled by the vessel’s DEIF Power-Management-System. A bus-bar breaker is also fitted in the main switchboard, allowing the aft thruster to be fed off the shaft alternator, while the forward thruster and domestic load is supplied by the gensets.

The vessel’s electrical power system is fitted for sliding frequency (60-50 Hz), by means of frequency converters for 400/440V and rotating frequency converter for 230V. This arrangement allows the main engine and propeller rpm to be reduced by 17%.

In the unlikely event of a main engine failure, the vessel’s full electrical propulsion facility enables Pathway to steam at up to 11 knots. A dedicated clutch fitted between the main engine and gearbox enables the shaft generator to function as an electric motor to drive a separate Marelli pony motor, being fed off the auxiliary engines. Up to 1,500 kW can be used for this diesel-electrical propulsion drive, which on engine trials gave Pathway a highly creditable speed of 11 knots.

The full electrical installation on Pathway was carried out by Karstensens Shipyard’s recently established subsidiary company KS Elektro A/S.

Two Brunvoll electrically-driven tunnel thrusters (bow 900kW/stern950kW) in which skewed-bladed propellers combine optimal thrust with low noise, assist vessel handling in confined areas and when keeping station to fishing gear.

599,000 litres of fuel can be carried in double bottom tanks, while the vessel’s freshwater capacity is 187,000 litres. 60t of seawater ballast can be carried in deep forepeak tanks, in addition to 55t held in a passive anti-roll tank positioned forward on the boat deck. This structure is a seamless continuation of the dedicated compartment housing the anchor windlasses and forward mooring winches.

Engineers John Leonard, Sandy Florence and Andrew Lemon, monitor the performance of all the vessel’s propulsion and generating machinery, catch storage and the comprehensive alarm systems from a separate sound-proofed control room and office, when sharing 24-hour watch duties. Situated on the port side of the main deck, the control room also houses the main electrical switchboards and the computer monitors for the MCS vessel management system.