North Sea mackerel, fished in close proximity to Shetland, was the first target species for the new Whalsay 75.4m midwater trawler Zephyr LK 394, when skipper Allister Irvine and crew started to establish the boat’s fishing credentials, reports David Linkie

A quick-fire shakedown trip east of Orkney yielded 500t of mackerel, which Zephyr landed at Lerwick. Skipper Allister Irvine reported that everything went very well on the maiden trip, and that the various new systems Zephyr features worked smoothly from the off.

Handed over to the Zephyr Fishing Company by Norwegian shipyard Larsnes Mekaniske Verksted AS at the end of September (Fishing News, 10 October), Zephyr is the fifth new vessel of the same name to be built for the Irvine family over 61 years. The family took delivery of the 66ft dual-purpose herring drifter/whitefish seine-net boat Zephyr LK 391 in 1958.

Zephyr steaming from Whalsay to Lerwick for the first time, at 15 knots.

This level of continuity underlines the extent to which fishing is of paramount socio-economic importance to the small island of Whalsay, which is home to 14 locally owned pelagic vessels and whitefish boats, together with scallopers and creel boats. This is a remarkable achievement for a community of around 1,000 residents on an island of just 7.6 square miles.

The main reasons for skipper Allister Irvine and his partners taking the decision to order a new vessel over two years ago were enhancing catch quality, fishing efficiency and crew/vessel safety.

Zephyr replaces her 23-year-old predecessor of the same name, which was sold to Namibia last year to fish horse mackerel.

Although less than 3m longer, the new Zephyr bears little resemblance to her predecessor. Major changes are significantly increased freeboard and pumping pelagic fish over the stern – a first for the owners.

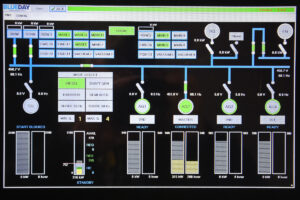

Screen displays on the video wall are selected from touchscreens.

With state-of-the-art catch-handling, refrigeration and landing systems, propulsion technology that produced a top speed of 17.5 knots on acceptance trials from Larsnes, and the latest wheelhouse electronics, supplied by H Williamson & Sons of Scalloway, Zephyr showcases the constant advancement in the design and specification of midwater vessels.

The long forecastle and a continuous boat deck, in the form of wide walkways either side of the inset dewatering system, together with more beam, will be particularly beneficial when Zephyr is fishing blue whiting on the Porcupine Bank, some 350 miles from Barra Head, in March.

The presence of six Caterpillar generators is another key feature of Zephyr. Supplied and installed by Lerwick-based DH Marine – Finning UK’s sole authorised Cat marine dealer for the Shetland and Orkney islands – the generators form a customised and fully integrated electrical power supply system specifically developed to provide optimum levels of running and fuel efficiency in years to come, in line with the owners’ requirements.

Pulling two SNG midwater trawls onto the net drums, which are arranged side by side on the shelterdeck.

At a time when a continual succession of similar vessels are entering service in the Norwegian fleet and landing pelagic fish to a highly discerning global marketplace, it is of paramount importance that multi-generation UK partnerships continue to show similar levels of long-term commitment, in order to compete on an equal footing with vessels they regularly fish alongside.

While Zephyr was rigging out, stern-on to the new Holmsgarth North deepwater pier at Lerwick, skipper Allister Irvine said: “Gradual evolution, both in terms of fishing areas and vessel design, meant that the time was right to move forward with a new boat, particularly for the benefit of the next generation.

“We are delighted with the end result, as there is no doubt that the yard, together with all the other companies involved, pulled out all the stops to deliver a splendid boat, both in terms of working efficiency and finish.

“While the boat represents a considerable learning curve for us initially in respect of the new technologies, as well as pumping aft, it is one that we are looking forward to. Changes and challenges are an ever-present factor in fishing, so we should be well-versed in meeting them head-on.”

Designed by Skipsteknisk AS, Zephyr is based on the Ålesund company’s well-proven ST-125 round bilge hull, the main dimensions of which are 75.4m LOA, breadth moulded 15m and a depth to shelterdeck of 9m. Zephyr’s underwater hull design mirrors that of Antares LK 419, which joined the Shetland fleet nearly three years ago and is skippered by Allister Irvine’s brother Lowrie Irvine.

Previous successful working relationships spanning two large-scale vessel modernisation projects led to the owners placing the order for their new boat with Larsnes Mekaniske Verksted AS. The hull was built to DNV-GL +1A1 Fishing Vessel TMON classifiation by Marine Projects Ltd at Gdansk, Poland, before being towed by tug to Larsnes for completion.

General layout

Zephyr’s crew, ready for the challenges ahead. Left to right: Willie Jamieson, Shaun Simpson, Richard Arthur, Callum Irvine, Brian Irvine, Allister Irvine, Johnny Simpson, John Lowrie Irvine, Allister Pearson and Maurice Arthur.

Below the main deck, the hull is subdivided into forepeak, bow thruster/sonar room, RSW pump and manifold room, insulated RSW tank section, engineroom, and aft peak with fuel and lube oil tanks.

At main deck level, the arrangements from forward are forepeak, RSW machinery room, forward RSW trunk section, central vacuum landing room, and the two aftmost tiers of RSW tanks. Internal passageways are arranged on either side of the RSW tanks to give ease of access between the various control, engine and machinery rooms.

The engine control room adjoins the main electrical switchboard room on the port side of the vessel’s centreline, forward of the main hydraulic pump room.

Two single-berth engineer’s cabins, together with a twin-berth cabin and a laundry room, are positioned along the starboard side of the hull.

The customary well-equipped engineer’s workshop is positioned towards the vessel’s centreline, adjoining an electrical store/workshop to port forward of the main hydraulic room. This, in turn, gives direct access to a large fishing gear store aft on the starboard side.

Two of Zephyr’s six Caterpillar gensets, supplied by DH Marine (Lerwick) Ltd…

One deck up, access from the trawl deck aft leads through a large gear store – where the customary array of spare trawl chandlery, and charging boards for the trawl sensors, are located – forward to an expansive crew changing room, where their protective deck clothing is stored in heated lockers.

The hospital cabin, which provides direct access to the shelterdeck, lies to starboard, aft of a trim room and a further three single-berth cabins.

On the next level (the boat deck), separate day and TV lounges lie to starboard of the mess room, where two large seven-sided tables surrounded by swivel chairs and heated food self-serve arrangements are prominent features.

Cook Shaun Simpson’s well-equipped stainless steel galley is positioned to port, together with a large walk-in dry-provision room, in which three chest freezers are fitted.

Six ensuite cabins, together with a walk-in room housing the array of computers for the vessel’s electronic equipment, are located on the next deck up under the wheelhouse.

A key visual characteristic of Zephyr is the eclectic array of photographs displayed along the internal passageways and in the main accommodation areas. These complement the superb level of internal finish found throughout the vessel.

Engineroom

… output from which is one of the functions performed by Zephyr’s Blueday vessel management system.

From the very beginning of the design process for the new boat, particular emphasis was placed on the choice of engineroom machinery and systems across all modes of operation.

This process was assisted by the longstanding working association, spanning 18 years, between Zephyr’s owners and DH Marine Ltd of Lerwick. Initial discussions that Zephyr’s engineers Brian Irvine and Richard Arthur had with David Henry on possible options quickly widened to include leading companies with which DH Marine regularly works. Once the main concept had been agreed, ongoing review and reflection led to small but significant changes being made as the design and installation of the system and software evolved.

Including six auxiliary generators, the end result is a significant first for a pelagic vessel. Each Caterpillar engine was specifically selected to run a predetermined range of machinery, thereby eliminating the need to have large generators running when power requirements are low.

Zephyr’s Wärtsilä 12V33 propulsion unit (6,960kW at 750rpm) drives a Wärtsilä 4,000mm-diameter four-bladed CP propeller system, housed in a high-performance fixed nozzle, through a matching Wärtsilä SCV 95 5.22:1 reduction gearbox. The efficiency of the centreline package, combined with the underwater hull form, is highlighted by the fact that Zephyr returned a top speed of 17.5 knots on trials.

Zephyr being conveyed downriver, after being built by Marine Projects Ltd, in preparation for being floated in a large dry-dock at Gdansk, before being towed to Larsnes by tug.

A PTO on the gearbox drives a Wärtsilä 3,100kWe shaft generator. When Zephyr is hauling and shooting the midwater gear, the gearbox PTO will be clutched in, enabling electric power for the electro-hydraulic motors to be supplied from the shaft alternator. This arrangement reflects the fact that when full power is required for the deck machinery, there will normally not be the same demand for power on the main engine, allowing it to meet the requirements of both the propulsion and hydraulic systems.

The electrical power (3.1mW) produced by the shaft generator can be replicated by the combined output of four Caterpillar gensets – two of which are located in the engineroom and two forward in the forecastle – which together can generate 2.7mW of power.

The two biggest generators, C32 models developing 940kW, are primarily intended to run the vessel’s power consumption when laying in with fish tanks loaded and running both the RSW refrigeration systems and ship’s load – which is estimated to be around 640ekW.

When all four auxiliary sets are synchronised and on the board, they can then drive the electrically powered Brunvoll tunnel thrusters, in which skewed bladed propellers combine optimal thrust with low noise. As well as optimising vessel handling in confined areas and when keeping station to fishing gear, the 1,300kW bow and stern thrusters have the capability to keep Zephyr off the shore in the highly unlikely situation of an emergency arising.

Zephyr landing her first shot of mackerel at Lerwick. (Photo: Sydney Sinclair)

A C18 genset of 565kW located forward runs all the machinery used when Zephyr is landing.

A C9 genset delivers 300kW to run the cranes or mooring winches when Zephyr is in harbour.

When Zephyr is berthed for extended periods between seasonal pelagic fisheries in Symbister harbour on Whalsay, where shore power is unavailable, a C7.1 genset of 175kW will run continuously to heat the vessel, together with the main engine.

A second C7.1 unit of 140kW is available as an emergency genset in a black ship situation. When Zephyr is lying at the pier, this engine can also be used as a second harbour set, and can back-feed the emergency switchboard to the main switchboard and run the vessel while berthed for extended periods.

Synchronisation of electrical supplies on Zephyr is one of many functions performed by a custom-designed Blueday vessel power management system. This highly advanced system identifies the output required and brings in predetermined generators as required. In addition to the main control screen, duplicated in the wheelhouse, engine control and main switchboard, individual screens are provided on the front of each cabinet so that the engineers can see at a glance the prevailing level of performance.

Walkways are arranged on either side of the hull at main deck level.

In another measure designed to maximise efficiency, heat generated by the C7.1 auxiliary engine is recovered by two separate systems. One, on the HT (high temperature) side, heats the main engine and keeps the engine to a steady 62°C. The separate LT (low temperature) system is fully integrated into the vessel’s domestic hot water arrangements, and supplies warm water to the Aeron air conditioning units, which then blow warm air through the vessel to keep the temperature at a steady 18°C.

DH Marine also supplied and installed the Nilfisk SC Delta high-pressure washing system, which is served by a series of jet lances and hose storage reels positioned throughout the vessel.

Zephyr’s double bottom tanks allow 583,000 litres of fuel to be carried, while the vessel’s freshwater capacity is 63,000 litres. A bulbous bow trim tank holds 105t of technical water, in addition to 77t held in a passive anti-roll tank positioned forward on the boat deck.

Midwater trawling arrangements

Karmøy Winch AS of Kopervik supplied the bespoke package of trawl deck equipment installed on Zephyr, based on the partners’ previous successful first-hand experience of its products.

The 91t core pull split trawl winches, positioned abaft the accommodation casing to port and starboard on the boat deck, are operated through a Karm Datatrawl system.

Spooled with 2,000m lengths of 38mm-diameter Oliveira trawl wire supplied by Selstad AS of Måløy, the winches give parallel elevated leads to the inboard hanging blocks suspended within the underside of the stern gantry, to which companionways give ready access. This arrangement ensures that the crew have clear and immediate access to the midwater gear from two levels when clipping on/off helper pennants/backstrops, etc.

Zephyr chief engineer Brian Irvine and David Henry of DH Marine, with one of the six Caterpillar gensets supplied and installed by DH Marine as part of a bespoke electrical power management system.

Midwater trawling is just one of the functions performed by the Karm Datatrawl system, which also delivers a full hydraulic management programme controlling the array of four 148kW and five 87kW electro/hydraulic power packs, along with two 6.4kW pilot motors, situated in a dedicated room aft on the port side of the main deck, in close proximity to where the majority of the trawl machinery is located. Another three 87kW units in the forepeak operate the deck crane anchor and mooring winches forward.

Selected operating modes matched to the working practices now being established on Zephyr are programmed into the Karm Datatrawl system. This ensures that the optimum combinations of hydraulic pumps are always available, allowing the operator to concentrate fully on activities on deck – of which the commanding trawl console in the wheelhouse provides an excellent view, assisted by a good clearance between the trawl doors.

Midwater trawls are worked from two 110t net drums positioned side by side on the shelterdeck. Three toe-end weight tracks, including a double middle one which is profiled to lead the respective weight to either the port or starboard shooting/hauling opening, are arranged across the transom.

When fishing in poor heavy weather, the two openings through which midwater trawls are worked can be sealed off by raising hydraulically operated gates, positioned aft of the four customary guiding-on pins.

A 71t life-line winch for handling the bag is located on the starboard side of the upper boat deck, directly above the trawl winch.

Two of the three generators housed in the forepeak.

A 57t tailend winch, used for pulling the bag to the midships gallows before the sock is taken up and attached to the fish pump, is positioned on the same level to port, in alignment with the 24in SeaQuest fish pump and hydraulic hose reel one deck down.

Three remote-controlled Karm deck cranes are also fitted. Two are positioned atop the trawl gantry; one is a net-stacker crane for general gear-handling duties, while the second crane is dedicated to the handling of the fish pump. A 4t/18m knuckle-boom crane covers the foredeck.

The usual selection of auxiliary winches are positioned around the trawl deck to assist with hauling the bag and other gear-handling activities on the trawl deck.

Two cable-sounder winches, rather than the more usual single unit, are mounted either side of the central net-stacker crane on top of the upper section of the trawl gantry. This arrangement ensures that should one of the cable winches fail for any reason when Zephyr is on the grounds, and possibly several hundred miles from harbour, fishing can continue as intended, rather than the vessel having to return to harbour as a result of the all-important trawl sounder not being available.

Fish pumping

Analogue and digital display panels are fitted on the distribution cabinets serving each genset.

At the end of a productive tow, hauls of blue whiting, herring and mackerel are pumped aboard aft on the port side of Zephyr using one of SeaQuest Systems’ well-proven and popular 24in fish pumps.

Aft pumping represents a new learning experience for Zephyr’s crew, and one that they are looking forward to getting to grips with in the coming weeks.

The SeaQuest pump is raised and lowered by a dedicated 4t/10.5m crane mounted directly overhead on the trawl gantry. When the pump is lowered into the sea, the hydraulic pipes from the drum on the foreside lead over a roller at the base of a secure deep slot, at the same time as 80m of Hydroscand DeltaFlex fish hose, supplied by DH Marine, is run off a pump-through reel situated directly below on the shelterdeck.

The fish hose permanently connected to the pump sits in a captive vertical slot in the port side of the transom, allowing the hose to run clear of the stern as the pump is deployed.

In an interesting development, the last section of the stainless steel delivery pipe through which fish are transported forward is fitted with a hydraulically operated telescopic section that aligns mechanically with the outlet on the hose reel.

Zephyr’s fish distribution arrangements amidships, viewed from above…

The usual short clear Perspex section incorporated into the first run of the main pipe enables the crewman controlling pumping operations to constantly monitor the flow of fish. When pumping, the flow of pelagic fish from the separator into the 12 RSW tanks is remotely controlled from a dedicated pump room located within the centre deckhouse, which also contains a dedicated sampling room. The customary succession of fish samples taken during pumping are delivered by pipe to the sampling room, where the weights of individual fish are recorded using a set of Marel M2200 electronic scales, from which the cumulative average fish size is transferred to a PC in the wheelhouse office, before being sent to prospective buyers ashore.

On entering the dewatering box, fish are directed upwards before sliding either forward or aft into transverse troughs, from where they are directed to the allocated RSW tank through stainless steel pipes, the use of which is controlled by remotely operated knife valves.

Two ammonia-based refrigeration plants, supplied by Johnson Controls (York/Sabroe) and situated forward on the main deck, deliver 2.5mKcal/h of cooling capacity, enabling pelagic catches to be brought down to the desired storage temperature of between 0°C and 1°C in often less than two hours, depending on the quantity of fish pumped aboard and the number of RSW tanks brought into use. The RSW system is served by four 500m³/hr circulation pumps and two 300m³/hr condenser pumps.

… and on the shelterdeck.

Fish quality is further enhanced by circulating purified seawater, supplied from a Normex ozone plant, through the 12 RSW tanks when the vessel is steaming, before the next shot of pelagic fish is pumped aboard.

The distribution of pelagic fish into the RSW tanks through tank sounding, and pump and valve control when pumping, are further functions performed by Zephyr’s Blueday vessel management system.

Pelagic catches from Zephyr are discharged to processing factories ashore by twin MMC 4,200-litre vacuum pumping systems, positioned at main deck level between the trunking of the fore and aft double tiers of RSW tanks. Operated by four 87kW compressor units, the system has a discharging capacity of up to 2 x 200t per hour.

When landing, a Perspex section in the vertical delivery pipe that passes through the control room allows the operator to constantly monitor the flow of fish.

Shetland specialist delivers advanced wheelhouse electronics

The wheelhouse interior from the starboard wing.

H Williamson & Sons Ltd of Scalloway, Shetland designed, supplied, installed and commissioned the state-of-the-art electronic equipment that is now performing well on Zephyr.

In addition to the main steaming and trawling consoles, the superbly finished wheelhouse includes an enclosed office area to port – in which images of the family’s previous six boats are engraved into the glass panels – and two relaxation areas for off-watch crewmen.

The main forward console comprises a Furuno/Böning video wall, in which five 55in 4K Hatteland pedestal-mounted screens are arranged in a shallow arc across the front of the wheelhouse, to give an integrated fishing bridge system. The layout of screen displays on the video wall is controlled by various presets. By using one of three 24in touchscreen controllers, skipper Allister Irvine can select his preference from these when Zephyr is searching for marks, towing, steaming or entering/leaving port.

H Williamson & Sons Ltd supplied and installed the wheelhouse electronics, including a five-screen-display video wall.

The touchscreen panels also have radar and sonar control functionality. So, for example, common functions of sonar operation, e.g. gain/range/tilt for each sonar, can be operated from one panel. The sonar and radar control units are hidden in the console, and can be pulled out if required.

The video wall is located in front of two NorSap skipper’s seats positioned between wing and island consoles, which together form the main navigation position.

Slim wing consoles, which come into play when Zephyr is manoeuvring in confined areas, are located at the forward corners of the wheelhouse.

The central fishing console aft provides a commanding view of midwater trawling activities across the stern. A further 16 26in Hatteland screens are fitted on the various consoles.

The main controls are positioned on island consoles between three NorSap chairs.

Zephyr is equipped with a comprehensive array of Furuno underwater acoustic equipment units. Initial location of pelagic fish is performed by Furuno FSV85 and FSV25 BB omni-sonars, of which the operational frequencies are centred on 80kHz and 20kHz.

Vertical echo detection is performed by Furuno FCV 1900B and Furuno FSS1-BB fish species discrimination sounders. A Furuno CI-68 BB current indicator provides tidal data at five different depths.

The aft-facing fishing station…

The performance of Zephyr’s midwater trawls when towing is monitored by a Marport net-monitoring system, from which information is received via a combination of three trawl eye units, six hybrid catch, two door and two catch eye sensors. The Marport trawl-monitoring system is integrated into the MaxSea TimeZero plotting system, to enable the position of the doors to be shown relative to the vessel.

A Simrad FS70 trawl sonar operates through either of the cable winches mounted atop the gantry.

Navigation requirements are handled by a Furuno FMD 3200 BB electronic chart display and information system (ECDIS), supported by two type-approved Furuno BB radars, together with a Furuno solid-state Doppler DRS6-NXT unit. This radar is also interfaced to a MaxSea TimeZero ProFish plotter, one of three chart plotting systems installed on Zephyr – the others being Sodena TurboWin and Telechart.

… and the forward starboard wing manoeuvering console.

GPS and heading data is provided by two Furuno GP170 type-approved GPS receivers, a Furuno SC70 satellite compass, a dual Simrad GC80 gyrocompass, and a Navitron NT999 dual-head autopilot system.

AIS information is handled by the latest-model Furuno FA170.

A Furuno BR500 watch alarm system gives peace of mind to the skipper and crew when Zephyr is steaming to and from the fishing grounds.

A full Sailor GMDSS package was also installed by Williamson’s, including 6310 MH/HF radiotelephone, 6222 Class A VHFs, Entel HT649 handheld VHFs, Furuno Felcom 18 Sat C and Furuno NX700B Navtex. Jotron EPIRBs and SARTs are also fitted.

Man-to-man communication onboard Zephyr is handled by Icom F1000 PMR VHF units built into the Geko protective helmets worn by the crew during fishing operations.

The Marport net-sensor system receives net data through six hydrophones simultaneously, giving excellent reception of all sensor data from the net and doors. The supplied catch sensors can transmit to both the trawl sonar and hull hydrophones, ensuring that catch sensor data is always available to the skipper.

Satellite TV is provided by a Sea Tel 120 1.2m TVRO package.

Swan Net-Gundry midwater trawl gear

Two new 80m braillers on the quay, ready to go aboard Zephyr as the vessel was rigged out at Lerwick.

Swan Net-Gundry supplied an extensive package of midwater trawls to Zephyr from its Lerwick and Killybegs depots.

This maintains the longstanding association of skipper Allister Irvine and his fellow shareholders with Swan Net-Gundry, which dates back over 30 years to when Zephyr and Antares steamed to Killybegs from Whalsay to collect custom-made midwater trawls from Swan Net MD Albert Swan, when the Shetland skippers took the decision to switch from purse-seining to midwater trawling.

SNG supplied two 870m Helix self-spreading herring trawls to Zephyr. These trawls are built with 25.6m meshes in the top and side panels, which are also colour-coded (red, blue, green, yellow) for easy identification of the panels. The bottom panel is made with 6.4m meshes. This trawl will shoot and haul easily, and will keep its shape and continue to fish while turning. The large forward meshes are also linked with DynIce locks.

The trawl tunnel consists of eight panels. This option has become the new standard with a lot of SNG trawls, giving the added benefits, compared to the traditional four-panel version, of better water flow, more stability, added strength and increased mesh opening.

One of the two 900m herring nets that Swan Net-Gundry made for Zephyr as part of a wide selection of midwater trawls.

When fishing mackerel, skipper Allister Irvine has a choice of three SNG nets: a 1,280m Helix self-spreading mackerel trawl with an eight-panel tunnel, a 1,434m left- and right-hand lay mackerel trawl with a Hex jet panel and a conventional four-panel tunnel, and a 1,638m left- and right-lay mackerel trawl with a Hex jet panel and a conventional four-panel tunnel.

Each of these trawls consists of 25.6m meshes on the top, side and bottom wing panels, and each panel has 12.8m meshes inserted at the mouth areas. All three trawls have been tried and tested, and have proven to be very successful trawl designs for SNG and its customers.

The switch to pumping pelagic fish over the stern, rather than amidships as on Zephyr’s predecessor, resulted in SNG making two of its newly designed 65m wide-body fast-flow braillers for the new vessel. Fitted with DynIce handle systems for splitters, the braillers also feature Dynet pumping sections for easy handling. This new design concept is also proving to be very successful for Swan Net-Gundry’s customers.

When fishing blue whiting west of Ireland in the early spring, Zephyr will carry an SNG 2,100m blue whiting trawl.

Five Zephyrs in 60 years

The 1980-built Zephyr at Ullapool, after being lengthened by 55ft in 1985.

Zephyr is the fifth vessel of the same name to be owned by the Irvine family.

The first, a 66ft dual-purpose herring drifter/seine-net boat, arrived at Whalsay in 1959 for Allister Irvine’s father Lawrence Irvine, after being built by J&G Forbes of Sandhaven. This boat, Zephyr LK 391, replaced skipper Lawrence Irvine’s first command, the 48ft Mary Jean LK 11, which he bought from Fraserburgh in 1948 before successfully fishing a seasonal combination of longlines, herring drifting and fly-shooting.

Allister Irvine joined his father and brothers Bobby, John Arthur and Lowrie on the family boat in 1964.

J&G Forbes & Co delivered the next-generation Zephyr LK 319, a 86ft purse-net and whitefish trawler, to skipper John Arthur Irvine and partners in 1976. The last wooden-hulled purse-net boat to be built, the 850hp Caterpillar-engined Zephyr had three CSW tanks of 60t capacity fitted in 1978, while retaining a 40t fishroom for boxed catches.

Zephyr Fishing Company’s previous 72.8m Zephyr is now fishing horse mackerel from Namibia.

Two years later, the partners took delivery of the 128ft steel purse-seiner Zephyr LK 394. Built at Fiskarstrand, Norway, the third Zephyr featured six RSW tanks and a Mirrlees Blackstone 2,140hp main engine. After being lengthened by 55ft in 1985, Zephyr rigged out the following year for midwater pair-trawling in partnership with Antares LK 419, skippered by John Irvine’s brother Lowrie. This proved the start of a successful 10-year pair-trawling partnership, which ended in 1996 when Zephyr was bought by Fraserburgh skipper George Tait and renamed Challenge FR 77, before becoming Alert FR 777 in 2002.

The fourth Zephyr, a 211ft midwater trawler, arrived at Whalsay from Flekkefjord Slipp & Maskinfabrikk in November 1996, one month after her sistership Antares LK 419 was completed at the same yard.

Featuring Wärtsilä 12V32E main engines, Antares and Zephyr generally pair-trawled together until 2009, when the 64.4m vessels were lengthened to 72.8m in extensive modernisation projects overseen by Skipsteknisk AS of Ålesund and carried out by main contractors Larsnes Mek Verkstad AS. Work included inserting a 6m hull section midships and extending the stern by 2.4m, fitting three additional RSW tanks to increase the vessels’ storage capacity to 2,200m³, installing a new fish-handling system, raising the wheelhouse and extending the whaleback.

Zephyr was sold to Namibia last year, and is now fishing horse mackerel from Walvis Bay.