Skipper Martin MacInnes and crewmen Angus MacFarlane and Ronan MacInnes are now fishing scallops off northwest Scotland on Silver Fern CY 197, reports David Linkie

The former Fraserburgh 18m trawler is the latest in a succession of vessels to benefit from long-term major conversion and modernisation projects carried out by Macduff Shipyards Ltd, dovetailed into its extensive build and general refit schedules.

Silver Fern is now working eight-a-side scallop gear, after being extensively rebuilt by Macduff Shipyards for Kallin Shellfish.

The large-scale nature of the work carried out on Silver Fern is immediately highlighted by a quick comparison of the vessel’s before and after side profiles. The original three-quarter-length shelterdeck has been replaced by a central walkway and considerably higher open bulwarks amidships. Further contrasts are provided by the fact that the new deck house is extended to the transom, replacing the previously open quarter, with a modern-look wheelhouse and the gantries associated with scallop dredging.

An equally large amount of work has been carried out internally. In the deck casing, this includes a new galley/messdeck area leading to the modern wheelhouse, for which McMinn Marine supplied and installed a comprehensive selection of new electronics equipment.

At the heart of Silver Fern, all the machinery, pipework and electrical systems in the engineroom have been totally renewed, after it was first stripped back to bare hull sides.

A similar approach prevailed in the fishroom, which was fully reinsulated and relined before Premier Refrigeration installed a new deckhead chilling system.

The well-proven towing and seakeeping characteristics of this class of vessel were among the reasons for Macduff Shipyards, together with Kallin Shellfish, taking the decision to implement such large-scale changes on Silver Fern.

Having taken delivery of the sub-15m automated scalloper Guiding Star CY 191 from Macduff Shipyards in 2015, brothers Donald and Hector Stewart were immediately interested when the potential of converting Silver Fern arose, as they had been looking to invest in a second scalloper of this class for some time.

Silver Fern in her previous role as a trawler, built by Herd & Mackenzie of Buckie in 1982 for Fraserburgh skipper Alex Wiseman.

Of 17.99m LOA and 6.3m of beam, the wooden-hulled Silver Fern FR 416 was built as a single-rig whitefish trawler by Herd & Mackenzie of Buckie in 1982 for Fraserburgh skipper Alex Wiseman. Featuring a Kelvin TBSC8 (370kW) engine, Silver Fern was the second of a new design of sub-16.45m registered-length hull, developed in line with new ticket requirements, to be built by Herd & Mackenzie, being launched a few months after the first, Providence BF 422, built for Gardenstown skipper David Watt.

For some years now, the similar-sized scalloper Kelly BCK 625, initially built as a gill-netter by Herd & Mackenzie before being converted first to side-trawling and later to scalloping, after being bought by brothers Konrad and Kamil Kosieradzki, has worked successfully out of Kallin, providing Silver Fern’s new owners with further insight into the suitability of this class of hull for scalloping.

Donald and Hector Stewart have a well-established association with scallopers that originated from Herd & Mackenzie’s Buckie yard. This began with the 40ft wooden-hulled Guiding Light CY 127, built in 1988, and continued in 1998 when this boat was replaced with the 15.5m steel-hulled scalloper Aquaria K 232, until they took delivery of Guiding Star in 2015 from Macduff Shipyards.

The links between Kallin Shellfish and Herd & Mackenzie are further strengthened by the fact that Duncan and DJ Macrae, who as equal partners with Donald and Hector Stewart established Kallin Shellfish in 2000, built the 40ft Stelimar CY 163 at the Buckie yard at the same time as the wooden-hulled Guiding Light. Today they fish the 13.4m steel-hulled scalloper Valaura BA 256, built by Alexander Noble & Sons at Girvan in 1987.

The sets of eight-a-side gear now performing well on Silver Fern were manufactured by Oban Scallop Gear Ltd, and mirror the similar gear onboard Guiding Star.

Loyalty to longstanding equipment and service providers by owner Kallin Shellfish Ltd, based on mutual benefit and ongoing customer satisfaction, is a recurring theme throughout Silver Fern, as shown by the fact that the scalloper, like Guiding Star and her predecessors, is insured by Sunderland Marine.

Work in progress at Macduff in June 2018 to virtually strip Silver Fern back to a bare hull.

Silver Fern is expected to work mainly two- to three-day trips, landing in line with the processing requirements of Kallin Shellfish Ltd. After putting a couple of shots ashore in the north of Scotland, Silver Fern made her first appearance and landing in the Western Isles on the first day of August at Lochmaddy, when family and friends took the opportunity to view Silver Fern for the first time, and all were highly impressed.

Hector Stewart said: “We are delighted at how Silver Fern has turned out. Macduff Shipyards knew what we wanted, so from favourable past experiences, we left them to do what they do best.

“Once again, they have delivered in style. We wanted an eight-a-side scalloper that will be safe and efficient to work. Early indications are that that is exactly what we have got.”

When Silver Fern arrived at Macduff from Fraserburgh in February of last year, boatyard workers started to remove all the vessel’s superstructure, deck machinery and trawl gantries. This resulted in only a short section of whaleback and a small part of the deck casing being left on the otherwise bare main deck.

Lifting off the original wheelhouse and forward section of deck casing also facilitated access to the engineroom, enabling the main engine, gearbox and auxiliary machinery to be removed relatively easily.

Before internal work commenced, Silver Fern was slipped at Macduff, where various jobs, including some replanking and recaulking, were carried out on the hull – which, as expected, was in excellent condition. While Silver Fern was out of the water, work began to replace the original single rudder with a new triple-blade unit manufactured by the yard, similar to the one fitted on Guiding Star, which has subsequently performed exceptionally well. A new 1,700mm-diameter nozzle and stern gear were also fitted.

Skipper Martin MacInnes (centre) with crewmen Aaron Edwards (standing in for Ronan MacInnes) and Angus MacFarlane (right).

The bulwarks were also heightened significantly amidships, to accommodate the planned fitting of catch conveyors on the side decks. On completion of this work, the outer sides of the hull, from the top rail to below the waterline, were sheathed with stainless steel sheeting, to give maximum protection against the daily abrasion associated with scalloping.

Working arrangements on Silver Fern are fairly standard for this class of vessel. The working deck is protected by a partial shelterdeck and runs along the centreline of the vessel from the wheelhouse to the aft gantry.

One key feature of the working arrangements onboard Silver Fern is the amount of space available on the clean main deck, and the ease of access to all key areas.

A second is the direct access to the quarters aft of the towing arms. In addition to enabling one crewman to monitor the gear as it comes up on a warp length differential of 10 fathoms, it also gives direct easy access to the dredges, thereby allowing anything attached to them to be cleared with optimum efficiency.

Manufactured by the yard, a two-drum trawl winch is positioned forward on the main deck. Fitted with a Hagglunds C100 motor, the winch is rated 15t core pull and is spooled with two 150-fathom lengths of 26mm wire, supplied by Tyson’s Rigging of Grimsby. The choice of wires was a direct consequence of the owners being consistently impressed by the performance of similar products in use on Guiding Star.

The under-spooled wires lead from the winch along the main deck either side of the fishroom hatch to sheaves positioned near the forward corners of the deck casing, from where they lead outboard over the catch conveyors to hanging blocks on the towing arms.

Of box section construction, the towing arms are pivoted at main deck level, midway between the aft end of the catch conveyors and the transom, close to the base of the stern gantry. Raised and lowered by ropes worked from the pulling-down Gilsons leading aft to a central point on the roof of the deck casing, the towing arms slot into secure holding brackets welded on top of the gunwale rail.

Two 5t Gilsons are mounted on the main deck close to the base of the conventional goalpost-style lifting gantry, where two 2t pulling-down Gilsons are also located.

The Caterpillar C18 ACERT engine delivers 357kW @ 1,800rpm.

When the eight-a-side scallop gear is lifted to the rail, individual dredges are tipped using a 1t winch and pivoting derrick mounted midway up the main gantry.

The contents of the dredges descend onto hydraulically operated slow-moving conveyors that lead forward along the bottom of each stainless steel reception hopper, to which raised gratings give ease of access. The conveyors lead king scallops and stones towards the fore end of the hopper, where a crewman picks selected clams and drops them into baskets held adjacent to the conveyor. Stones are returned to the sea through a chute leading out through the side of the vessel at main deck level, when the crewman advances the conveyor.

After washing, baskets of selected scallops are transferred through a vertical chute down into the fishroom for bagging, prior to being stacked.

Fully lined and insulated by the yard to minimise heat transfer from outside the vessel, Silver Fern’s fishroom, which has an estimated working capacity for some 300 bags of scallops, features an engineroom bulkhead and deckhead-mounted chilling system installed by Premier Refrigeration Ltd of Fraserburgh.

Silver Fern is powered by a Caterpillar C18 ACERT main engine delivering 357kW @ 1,800rpm, coupled to a Masson Marine gearbox with a reduction ratio of 7:1.

The choice of main engine was because of the favourable reports, both in terms of towing performance and fuel efficiency, that these units have consistently attracted since they were developed.

A PTO on the back of the gearbox provides a back-up hydraulic system to the main one, driven through a Fenner coupling from a John Deere 6068TFM50 auxiliary engine delivering 115kW @ 2,300rpm. The standby system can be used to drive the conveyor belts along the bottom of the catch hoppers when the main hydraulics are not running, in addition to serving as a retrieve pump for the winch should the auxiliary engine fail to start. This arrangement is identical to the one that has performed well on Guiding Star for the past four years.

A Beta Marine 19.8kVa single-phase 240V genset is also installed in the engineroom. The genset provides power for equipment used on deck to maintain the dredges.

RD Downie Ltd of Fraserburgh carried out a full rewire of Silver Fern and manufactured the vessel’s distribution boards.

On completion of all external and internal work, Silver Fern was fully prepared and repainted by David Paterson and his team from Alexander Paterson Ship Chandler & Ship Painters of Macduff, in association with Macduff Shipyards, during which time the scalloper was reregistered CY 197.

McMinn Marine wheelhouse package

Silver Fern’s electronic wheelhouse equipment was supplied, installed and commissioned by McMinn Marine.

McMinn Marine supplied and installed a comprehensive selection of electronic equipment in the new wheelhouse…

Six 19in AG Neovo TFT screens, flush-mounted in two tiers in the shallow forward console, provide skipper Martin MacInnes with a constant display of information on the seabed configuration relative to the scalloper’s location.

The main Tenfjord steering and Kobelt engine controls are arranged on a small island console positioned on the starboard side of the skipper’s chair. Duplicate steering/engine controls are located on either side of the wheelhouse.

The importance of accurate vessel positioning relative to the selected – and usually small-scale – scallop grounds being fished is shown by the presence of an Olex plotting system incorporating a ground discrimination module and a Trax V7 unit incorporating AIS, ARPA, tide modules and a UK chart pack.

A JRC 130 BB single-frequency (50kHz) colour sounder with bottom hardness output is interfaced to the Olex plotting system.

Details of Silver Fern’s location are processed by an Onwa KP32 GPS receiver, and heading is provided by a JRC JLR-21 GPS compass.

Steering and navigation are taken care of by a Navitron NT777 digital autopilot, RD33 heading display and three remote tiller units. A JRC 334 10.4in LCD radar is also fitted.

Communications and safety equipment fitted on Silver Fern includes Sailor 6215 and Icom M323 DSC VHFs, Icom handheld VHF, Emtrak Class A AIS, and an Intellian i2 satellite TV system.

McMinn Marine also installed the vessel’s CCTV system, from which images from eight cameras, providing constant coverage of the engineroom and activity on deck around the main winch, Gilsons and catch conveyors, are displayed on two adjacent screens.

Kallin Shellfish Ltd

King scallops from Silver Fern are among the range of locally sourced seafood processed for retail and wholesale outlets by Kallin Shellfish on the small island of Grimsay, North Uist.

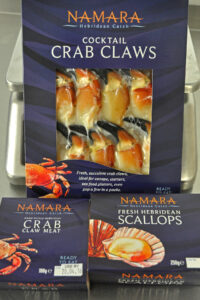

Some of the products that Kallin Shellfish markets through the Namara Hebridean Catch brand.

The family-run company produces a wide range of value-added shellfish products for an array of retail outlets. That these include supermarkets, online sales, restaurants and regular exports to Europe reflects the high reputation Kallin Shellfish has gained in what can only be described as a highly competitive market.

Kallin Shellfish began as a partnership in 2000, when Donald and Hector Stewart, together with Duncan and Donald Macrae, were longstanding fishermen on the local scallop dredgers Aquaria K 232 and Valaura BA 256, selling their catches to a local company that dealt in all types of shellfish, before it went into liquidation. Faced with the prospect of having no market for their prime-quality locally caught scallops, the two sets of brothers purchased the existing premises from the liquidator.

A good working relationship was quickly established with Salmac Sales Ltd of Aberdeen, which was keen to purchase scallops from the newly formed Kallin Shellfish Ltd. As the Grimsay company developed and diversified into other shellfish, the association proved mutually beneficial, and today, Salmac continues to be Kallin Shellfish’s largest customer.

Initially, Kallin Shellfish employed six people with scallop-processing experience, at the same time as Duncan Macrae and Hector Stewart stepped ashore from their boats to try to make the new venture work. Realising the stark truth that failure was not an option, the partners also bought supplies from other scallop boats that fished in the area on a seasonal basis, in addition to processing catches from the two family-owned boats. As a direct result of this determined approach, Kallin Shellfish had a turnover in the first year of operation of around £600,000.

Moving forward to the present day, during which time Kallin Shellfish has invested in modern processing equipment and staff training, as well as working diligently to establish new markets for a wide range of value-added seafood products to help the company develop, 30 local people are now employed, and Kallin Shellfish has an annual turnover of some £3.5m.

Kallin Shellfish staff shucking scallops.

During a period of sustained gradual expansion, Kallin Shellfish has also diversified into processing other shellfish, including live creel-caught langoustines, brown crab and lobsters.

On arrival, cases of tubed langoustines are immediately placed in one of a series of large storage tanks, in which the refrigerated seawater is kept at an optimum level of around 5ºC.

Langoustines that are destined for export are subsequently removed from the storage tanks for further selection and packaging into polystyrene tube cases, before being delivered by road to France and various other locations in Europe.

Brown crab are cooked in-house before an experienced workforce produces a variety of hand-picked retail products, including vacuum-packed sleeves of the always popular crab claws.

In addition to a retail shop on the premises and a popular online facility, Kallin Shellfish supplies a long list of island businesses as well as many retail outlets throughout Scotland, including the Scottish Co-op, which now stocks a full range of seafood products packaged under the Namara Hebridean Catch brand.