Everyone connected with Brixham is approaching the traditional Trawler Race this weekend on the crest of a wave, as all sectors of the local industry at the UK’s leading port continue to benefit from the welcome combination of healthy stocks and high levels of consumer demand for top-quality seafood.

Above: The Brixham scalloper Constant Friend returns to harbour at the end of another trip. (Photo: Martin Johns)

2016 saw Brixham return an all-time record catch value of £30.7m, an increase of 31% compared to the previous year’s total of 23.4m. Consistently good prices on Brixham market, particularly for cuttlefish (Brixham’s ‘black gold’) was the main reason for such a dramaticrise, during a year in which the total catch tonnage rose by 7% (883t) to reach 13,262t.

Brixham inshore skipper Trevor Parnell prepares his catch of morning mackerel for sale at the auction. It was 60kg, good sized fish and, due to the present scarcity of mackerel, made up to £5/kg.

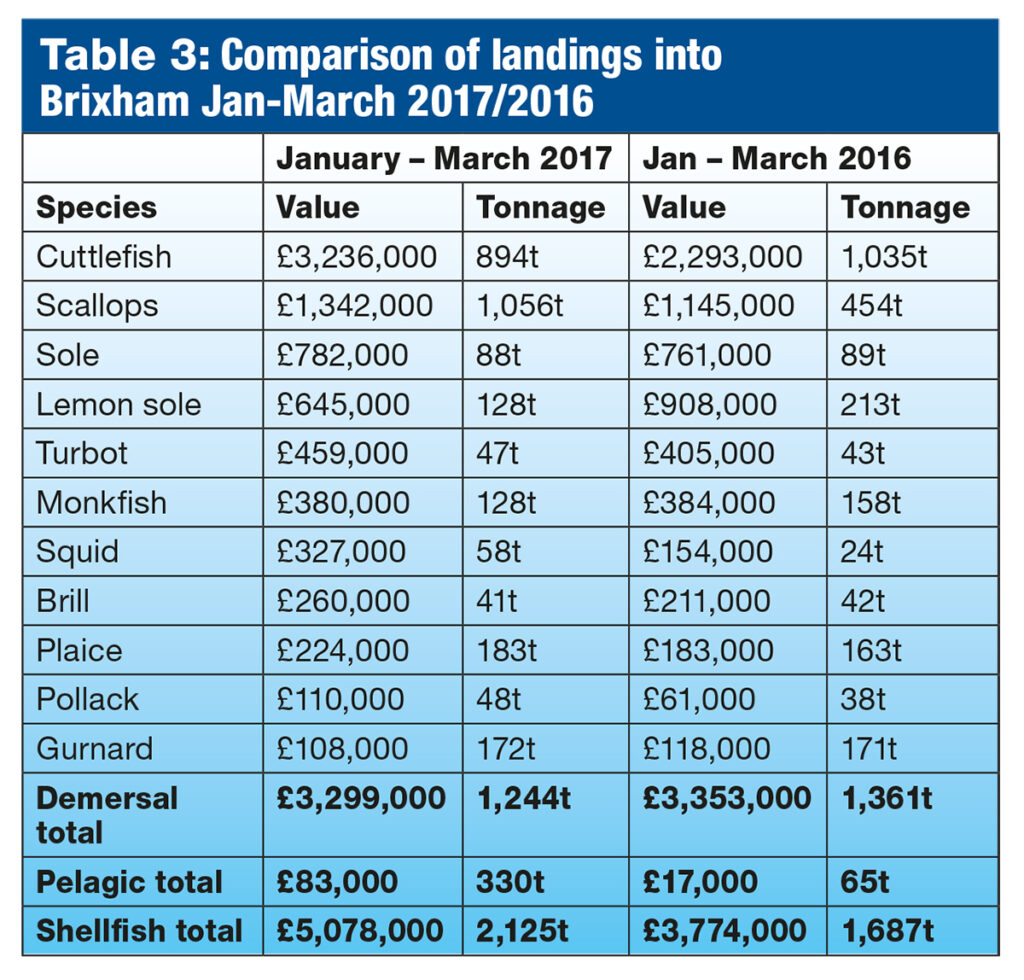

This strongly upward trend has been continued in the first quarter of this year, in which a catch value of £8.5m is 20% higher compared to £7.1m for the first three months of 2016. A 39% rise in the value of cuttlefish catches to £3.2m, achieved despite a 16% (141t) fall in quantity, was again the main reason for the further rise in the value of landings at Brixham. (See Table 3).

The mixed fleet of beam trawlers, scallopers and day haulers that land a wide diversity of top-quality prime fish into a modern purpose-built fishmarket, ensure consistent level of supplies that are eagerly sourced by discerning buyers and end consumers alike.

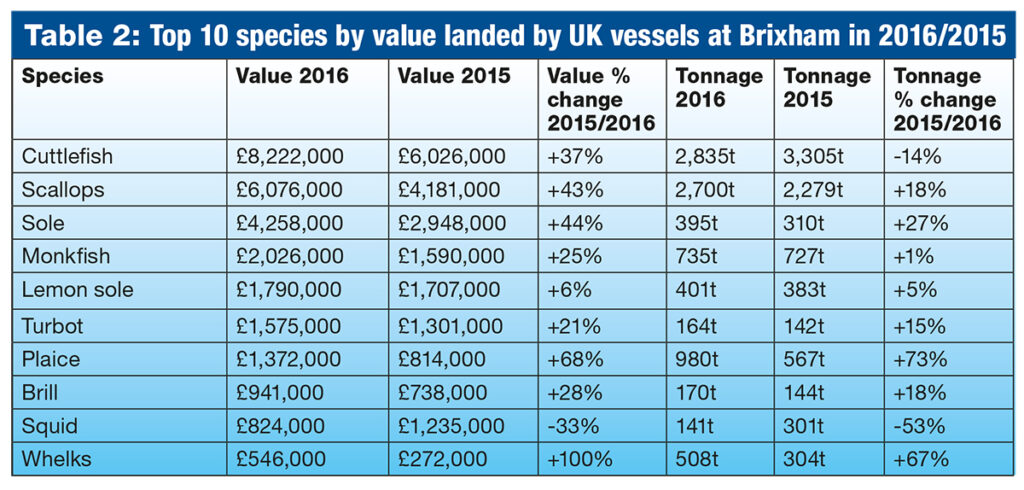

One of Brixham’s key strengths is the broad range of catches landed into the market, as shown by the fact that that seven species – cuttlefish, scallops, sole, monkfish, lemon sole, turbot and squid – each contributed over £1m in terms of annual catch value.

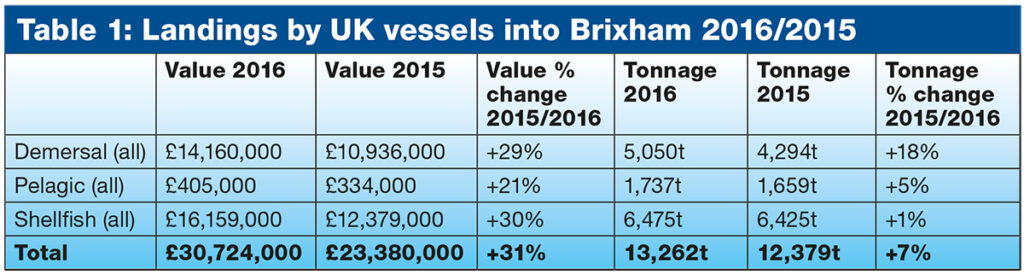

It is particularly pleasing to see that with respective catch value increases of 29%, 21% and 31%, the demersal, pelagic and shellfish sectors each made a strong contribution to the 2016 record. (See Table 1).

Equally encouraging is the fact that nine of the 10 top species landed at Brixham last year returned increased catch values.

At £8.2m, cuttlefish is the single most important species caught by the Brixham fleet, followed by scallops (£6.1m) and sole (£4.3m). (See Table 2).

The visiting Jersey trawler L’Ecume J 158 berthed in Brixham.

Brixham skipper Dave Driver’s trawler Girl Debra heads in to land at Brixham.

The extremely encouraging level of performance being achieved at Brixham is testimony to the huge amount of effort and forward thinking all those associated with the catching, marketing and processing sectors have put in for the past decade and more. That this included a number of particularly challenging and difficult years, illustrates how far Brixham has come, due entirely to the commitment and determination of all involved.

While further challenges almost inevitably lie ahead, including post-Brexit fisheries management and landing obligation requirements, they can be left astern for a few days as fishermen and their families celebrate Brixham Trawler Race weekend on a well-deserved high. Phil Lockley reports.