Share a day in the life of Cefas fisheries technician, Rose Finneran

“I love what I do,” Centre for Environment, Fishers and Aquaculture Science (Cefas) fisheries technical Rose Finneran told Fishing News. “Everyone says that I’m the Cefas poster girl – at every single outreach event, if anyone wants to know anything about Cefas or the job, I’ll be there. That’s because I never knew this career was an option growing up.”

Rose is based at Cefas’ headquarters in Lowestoft – but a career in science nearly didn’t happen at all for the 23-year-old.

“I wanted to be a journalist. I really excelled at English, and took English A-level in college. But whilst there, I saw on the bulletin board that Cefas had a masterclass event at the Lowestoft site. My mum raised me to be in touch with the environment and give back to the world – so I went to see what they did there.”

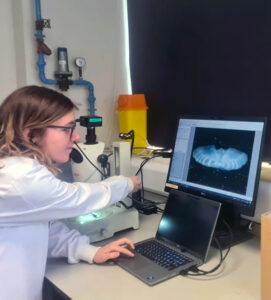

Rose reading the otolith from a plaice. She and her team process around 60,000 otoliths a year, providing crucial information about the health of the oceans and the sustainability of stocks. Of the otolith on the screen, Rose said: “We’ve got some lovely rings there, so we can see that’s quite an old plaice.”

As part of the masterclass, Cefas’ otolith processing team was holding a demonstration – it was then Rose ‘fell in love’ with science. “I was gobsmacked. It was amazing. There were people scalping fish and taking otoliths out, and they were like: ‘Come and try it.’ I knew then that I was going to do everything in my power to get a career at Cefas.

“However, at this stage I had no science-related qualifications. So I waited – and then, miraculously, an apprenticeship at Cefas came up.”

Following a successful interview, Rose joined Cefas as a metals apprentice, analysing heavy metal bioaccumulation in fish and sediments, before moving on to the otolith processing team – a group of five core laboratory members, an otolith scientist, the national age determination co-ordinator and a team leader.

Processing otoliths doesn’t just help determine the age of a fish; it can also be crucial in understanding the health of oceans, as well as the sustainability of stocks.

“Processing otoliths enables us look at stock levels in the ocean, so we know what stocks are like in certain geographical areas, what the age of that stock is, and its health.”

A remarkable amount of information can be derived. “We’re not just processing otoliths and reading them, we’re also looking into otolith chemistry. We’re looking at laser ablation, which is where we can look at the chemicals inside the otolith. We can study migration patterns, the habitat in which the fish lived, diet, water temperature, the presence of pollutants – just from what’s basically a calcium carbonate deposit beside a fish’s brain.”

Rose’s day begins at 7am. “We’re all early birds in our lab.” The tasks for the day ahead vary, and can involve mounting, cutting, polishing and reading otoliths.

Firstly, at the start of the week, we’ll do our calibration checks. We’ve got to make sure that our balance is functioning correctly, and our fridge is the correct temperature.

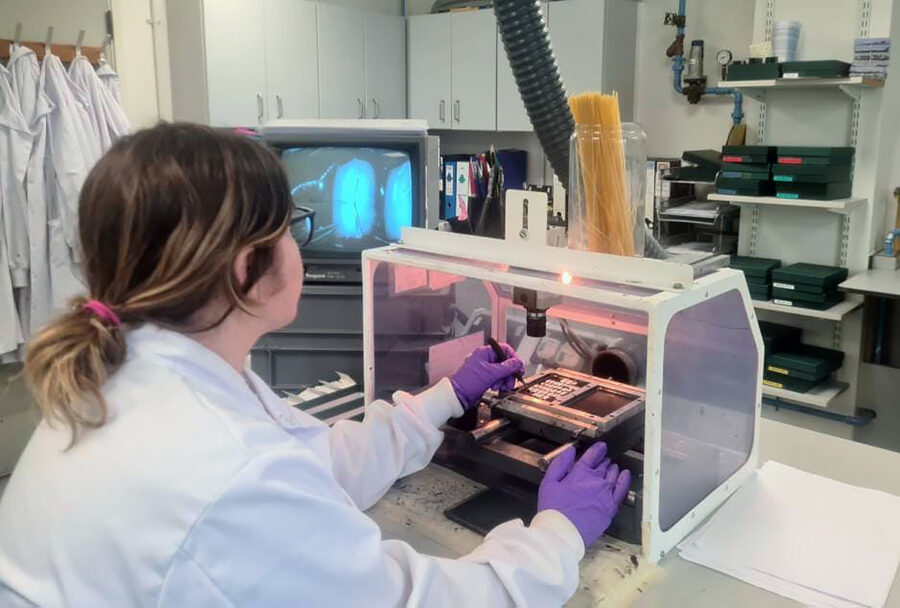

Rose using the Accutom-5, a machine designed to cut otoliths from smaller and more fragile species. The chemical make-up of otoliths differs for each species, with environment also a factor. “Where water temperature doesn’t differ much, we don’t see beautiful ring variations.”

“For the days when I’m mounting otoliths, we have a whiteboard which tells us all the species that we have in, what month they were caught and how many there are.”

Different equipment is employed for the cutting of otoliths, depending on the species involved. For small and more fragile fish, like sole, the Accutom-5 machine is used – with Rose’s job being to ensure the accuracy and quality of any cutting.

“Sole otoliths are quite small. They’re mounted in square moulds, and I have to make sure that the scoreline on the mould, which represents the line where I mounted them – the nucleus line – is in the exact position for the blade to cut precisely.”

Sole otoliths are also sometimes dyed, to help bring out the appearance of the rings. “We use a red dye, and the proteins in sole come out more vibrant when they’re dyed. We dye them for about 45 minutes in a red solution, and then dry them with a hairdryer – very technical, I know!

“The protein takes to the dye very well, so you get really beautiful rings that are more pronounced.”

Rose’s role also allows her to experience other areas of work Cefas is involved in, including an upcoming trip to Belize with the organisation’s marine litter group.

“At Cefas we’re really blessed in that I’m not limited to my core position as fisheries technician. I’ve been able to work one day a week with our plastics laboratory, and I also work in our outreach team. We have schools come in, we attend festivals, and I also took part in Women in Science Day.”

With the career she never knew existed now well underway, Rose’s happiness is evident. “I’m always thankful and count my blessings because I didn’t know this career was ever going to be available for me.

“Cefas has always been really kind to me, so I want to tell the world how great Cefas is, and how great a career in the marine industry and fisheries science is.

“I always want to fly the flag. Some may say that’s pretty sad – but I love my career.”

This story was taken from the latest issue of Fishing News. For more up-to-date and in-depth reports on the UK and Irish commercial fishing sector, subscribe to Fishing News here or buy the latest single issue for just £3.30 here.

Sign up to Fishing News’ FREE e-newsletter here.