Seafish recently refreshed its longstanding working relationship with the Sintef Flume Tank in Hirtshals in northern Denmark by running a two-day basic fishing gear training course there for 14 non-fishers.

Consumers increasingly expect responsibly sourced seafood, which means there is a need for more sustainable wild-capture fishing practices. A crucial element is the use of selective gear to reduce bycatch, and this is increasingly important to both the UK fishing fleet and the wider seafood supply chain.

The group attending the course consisted of senior policy-makers from across the UK devolved nations, and representatives from several fish processors and high street retailers. The course was delivered by Seafish fishing gear innovational manager David Warwick and ex-Seafish gear technologist Mike Montgomerie, with support from the staff at the flume tank. As the facility is designed for the demonstration of, and research on, towed gears, these comprised most of the gears presented, along with some gill-nets.

The course started with an introduction to trawl gear with a large hopper trawl, outlining the main parts of a trawl rig from the warps through to the codend, together with an explanation of the purpose of each part of the gear and how it works.

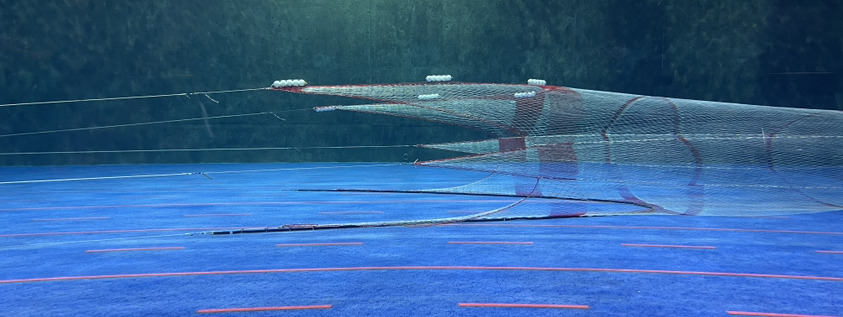

The high-lift three-bridle trawl being demonstrated in the flume tank.

A hopper trawl fitted with a separator panel.

Over 30 different nets were then shown in the tank, starting with beam trawls, explaining how a beam trawl works and why it is suitable for its target species.

The group discussions focused on the selectivity and environmental credentials of a beam trawl in relation to other gears, as well as looking at what advances have been made in the South West beam trawl fleet in recent years – in particular, Project 50%, a collaborative project between Cefas scientists and UK beam trawlers, testing roller-ball footropes and, more recently, trials of the hydrodynamically shaped Sumwing beam trawl.

A small flatfish trawl was demonstrated, with the net attached close behind the trawl doors and gradually moving through a range of trawls, using sweeps to herd fish into the net; these are used around the UK to target fish and Nephrops that live close to the seabed.

As several of these trawls were fitted with different selective gears, this led to in-depth discussions as to the selective properties of each, and how practical they are for the fishermen to use and for the legislators to regulate.

A standard prawn trawl alongside a coverless prawn trawl in the tank.

The next group of gears demonstrated in the tank were some higher-standing whitefish demersal trawls such as balloon trawls, side-panel trawls and three-bridle trawls. This included some adjustments to the trawl to demonstrate how fishermen can alter the ground contact and headline height of a trawl. It also highlighted how important it is for fishermen to ensure all the sweeps and bridles are the correct length, and that the gear is rigged correctly in order for it to work efficiently.

Then it was on to a couple of pelagic trawls, not only showing how the gear works but also clarifying a few myths about the actual size of some of the larger pelagic trawls.

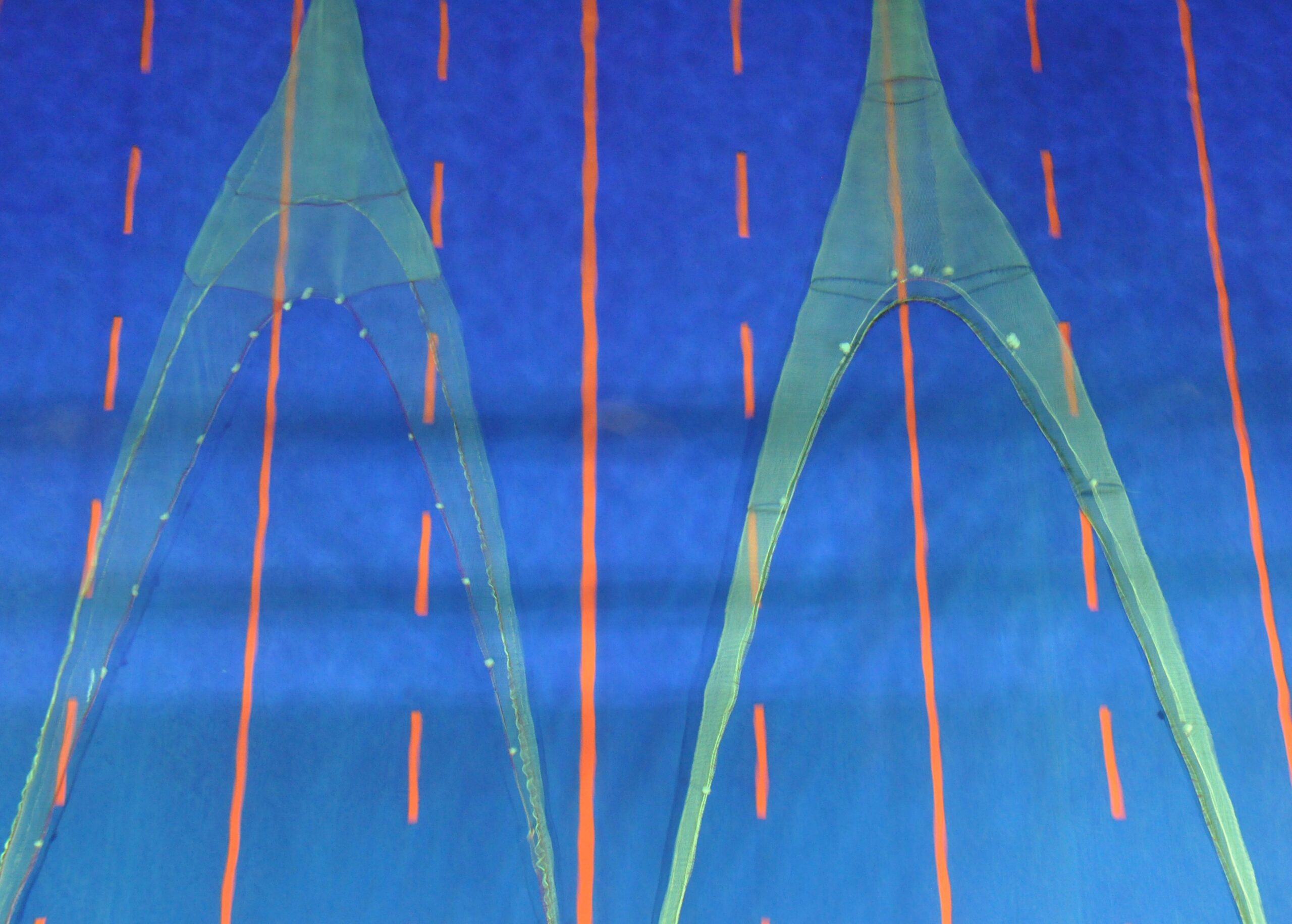

Next in the tank were two bottom gill-nets. It was interesting for the group to see the nets hanging vertically, like a curtain, in the water, rather than just in a tub on the harbourside. Here the monofilament twine is almost invisible, and it is easy to see how fish of a certain size can swim into the nets and get caught in the meshes, while the smaller fish can swim right through without getting caught.

When the waterflow was started to simulate a tidal current at sea, it could be seen how in any tide at all, the nets will lay over and be very close to the seabed.

Models of twin-rig sole nets from South East England, and twin-rig Nephrops trawls similar to those used in North East Scotland, were next in the tank to demonstrate the intricate rigging of both, and enable discussion of the merits of twin- and multi-rig gear when compared to single trawls. This was further demonstrated by changing the twin-rig Nephrops gear to a quad-rig set-up with four smaller nets.

Much of the work on the second day of the course covered many of the selective gears that have been tested in UK fisheries over the last 25 years – gears such as square mesh panels, coverless trawls, large diamond mesh panels, extra square mesh panels, separator panels, rigid grids, inclined netting grids, and different codend configurations such as square mesh and four panels.

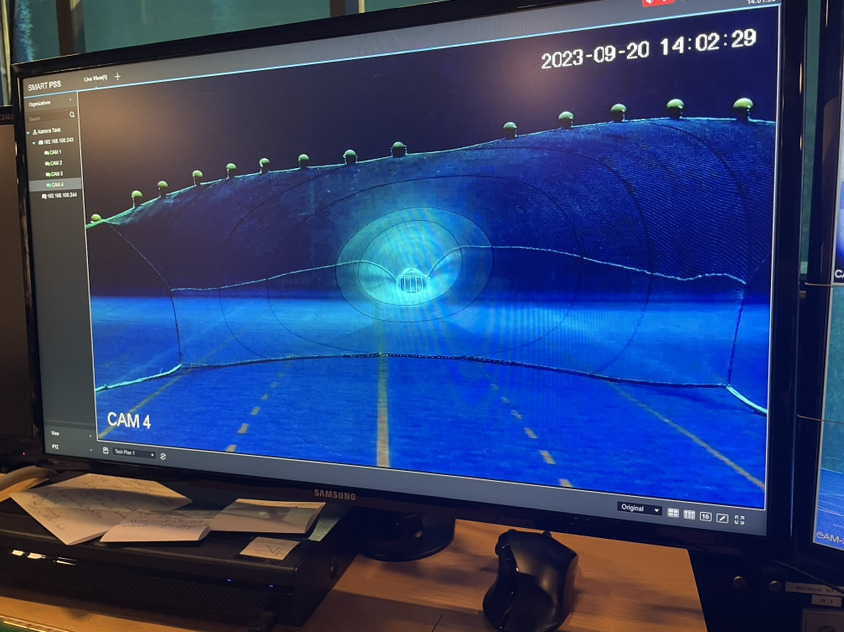

A camera view into the mouth of a large trawl with a cetacean excluder grid fitted.

These all created much discussion, with the group asking questions like: “Is it in use by industry?” “If not, why not?” “How would this help the vessel’s environmental and sustainability credentials?” and “Would this help to retain fish quality?”

Many of these discussions on selectivity, catch quality and innovation continued over dinner in the evening. These discussions were indicative of the ongoing supply chain engagement, which is vital in continuing to advance sustainability in the UK fishing sector.

This course involved a highly engaged group of UK supply chain stakeholders, and there were many complimentary comments from the participants, such as: “Thanks again for everything that you organised. It was a superb course/trip – thoroughly enjoyable.”

Another said: “It was so lovely to meet you and the Seafish team. You all made the trip so enjoyable. Thank you so much for inviting me on the course and for all of the organisation and planning involved. It was fantastic and extremely beneficial. I am so happy I attended. I’m looking forward to what’s next for the group.”

The course attendees included policy-makers and representatives of processors and retailers.

Seafish has been using the Hirtshals flume tank for delivering training courses to both fishermen and non-fishers since the Hull Flume Tank closed in 2014. It is currently exploring possible sources from which to secure funding to resume running its very successful trawl gear technology courses for UK fishermen. In the past, trawl fishermen from all around UK have benefited from attending these courses.

New operator for flume tank

During the time that Seafish has been using the Hirtshals flume tank, it has been run by Sintef of Norway, which has operated the facility since 2000. Recently, Sintef signed an agreement with the North Sea Science Park, which has now taken over as the operator of the Hirtshals flume tank through a new subsidiary, Flume Tank North Sea A/S.

The purpose of the new subsidiary is ‘to operate and develop the flume tank on a commercial basis, offering tests, development, education and demonstrations of fishery technology, equipment for aquaculture and other subsea technology for use in marine environments’. The company may also participate in research and development projects.

A group photo at the Hirtshals flume tank taken when Norwegian company Egersund Net was testing gear there. Left to right: managing director Mette Hyldegaard Roussis, Alina Pellegrinelli, Monica Dybing of Egersund Net, Oivind Fedoy of Egersund Net, Dennis Poulsen and Morten Holm Jensen. Missing from the photo are the two former managers of the flume tank, Kurt Hansen and Jens Peter Kofoed, who are now consultants to the new operation.

The current and very competent staff have all been offered transfers to Flume Tank North Sea A/S. The new managing director is Mette Hyldgaard Roussis, previously project manager at the North Sea Science Park, who can be contacted via: mhr@ nordsoemail.dk or on: + 45 4032 3096.

“We are looking forward to co-operating with the customers and users of the flume tank. We are very pleased that we have secured highly specialised know-how and jobs in Hirtshals. We will continue the activities in the flume tank, fulfil all tasks agreed with customers, and initiate an ongoing dialogue with customers, hoping that they will also provide input when we will shape the future strategy for the flume tank,” said Mette Hyldgaard Roussis.

“We are off to a fine start – bookings look promising, and new contacts are coming in.”

This story was taken from the latest issue of Fishing News. For more up-to-date and in-depth reports on the UK and Irish commercial fishing sector, subscribe to Fishing News here or buy the latest single issue for just £3.30 here.

Sign up to Fishing News’ FREE e-newsletter here.