Mooney Boats complete Danish-designed 25.6m twin-rig prawn freezer trawler for Clogherhead.

The custom-designed 25.6m multi-rig prawn freezer trawler Audacious DA 14 berthed at her home port of Clogherhead on 22 December, after being completed ahead of schedule for brothers David and Niall Kirwan by Mooney Boats Ltd at Killybegs, reports David Linkie.

Above: Starboard quarter view of Audacious.

While being fitted-out in just six months at Killybegs, and after arriving at Clogherhead, the trawler’s impressive lines, layout and build quality, together with the level of finish of Audacious, drew many favourable comments from experienced skippers and owners in Ireland.

On completion of the necessary paperwork, Audacious is expected to immediately leave Clogherhead to start fishing later this month.

Having successfully operated three ex-French trawlers, Ambitious DA 62, Courageous DA 18 and Virtuous DA 80, for a combined total of more than 25 years, owners David and Niall Kirwin understandably opted for similar well-proven working arrangements in their new purpose-built trawler.

That these were incorporated into the final design by Ove Kristensen of Vestværftet ApS of Hvide Sande, Denmark, explains the strong Danish influence on the hull lines of the stylish Audacious, which features a continuous round bilge hull form up to the shelterdeck, which extends virtually to the transom, where a bank of six net drums are mounted above the open quarter.

The Audacious project started three years ago when David and Niall Kirwin looked closely into the feasibility and viability of building a new boat, when maintenance costs, fuel efficiencies, crew safety and comfort, product quality and the large reduction in carbon footprint were fully considered.

Favourable outcomes subsequently led to Ove Kristensen being asked to design the new vessel, before contracts were signed in May 2014. The hull was built in six months at Riga Shipyard, before being towed from Latvia to Killybegs in May 2015 for machinery installation and fit-out by Mooney Boats Ltd.

This further strengthened the already well-established association between Vestværftet ApS and Mooney Boats which, just six months previously, had delivered the 23.99m prawn freezer trawler Patrick C DA 77 to skipper Niall Connolly and his father Seamus.

Built to Bureau Veritas specification, as stipulated for new Irish vessels since 2007, Audacious, like Patrick C, features extensive deck machinery and engineroom packages supplied by a number of well-known Irish companies, including EK Marine and Padmos, with whom David and Niall Kirwan had previously well-established working relationships. These ensure that the state-of-the-art new vessel very much reflects the new-build capabilities available in Ireland, which it is hoped Audacious will help augment further in years to come.

David Kirwan said: “We are delighted with the end result. Having previously worked with Lee Mooney, we knew the high standards of workmanship the yard delivers. Together with all other companies involved in the project, they have delivered in every aspect, including completing Audacious ahead of schedule.

“From the outset, whatever small additions or changes we requested when the hull and superstructure was being built in Latvia, or during fit-out, were immediately provided on production of a suitable drawing. The quality of work throughout Audacious is self-evident, and we are fully confident that the vessel will perform consistently well in years to come.

Father Peter Murphy blessing Audacious at Clogherhead, under the shelter of an umbrella held by ex-Harbourmaster Paddy Hodgins as David Kirwan, together with his wife Julie and children Moya, Evie and Elliott, listen intently.

“With the small quotas Irish boats have to work to, and boats being ring-fenced out of certain species, we felt we needed to be in a position to catch our quota in a more efficient and cost-effective manner, hence less fuel, and fewer CO2 emissions. The latter is of particular importance, as evidence of reduced carbon footprint is increasing being requested by our customers.

“The catch comes in over the stern, up the conveyor, on to the sorting bench, through the washer and into the packing area. After being blast-frozen down to minus 30°C and stored at minus 20°C, the next time the product sees daylight is when the prawns are in a retail shop in France, Italy or Spain.”

Lee Mooney, MD Mooney Boats Ltd explained: “The yard took on an extra 10 workers for the contract, bringing our total to 53. If you consider the jobs created with all the subcontractors, there were about 100 people employed on Audacious. Providing jobs locally is an important consideration for the yard in all its undertakings. Everything for Audacious, including engines, deck equipment, electrical systems, electronics, refrigeration and ice machines, fishing gear, water pumps, hydraulics and lifesaving equipment, was sourced within Ireland.

“Once installation and fit-out started, the emphasis was on the quality of the finish. We are hoping that this build, as well as Patrick C, will lead to more contracts in the future.”

Of round bilge hull form, Audacious has main dimensions of LOA 25.6m, reg length 23.5m, beam 7.5m, depth moulded 4.4m, draft 4.6m and GT 230 tonnes.

Under the virtually full-length steel shelterdeck, a partitioned bulkhead positioned across the vessel’s full beam directly under the trawl gantry, that includes a sliding door, separates the open quarter from the catch-handling areas arranged along the starboard side of the main deck.

Swan Net-Gundry supplied a full package of 18- and 26-fathom quad- and twin-rig prawn trawls to Audacious.

Promoting optimum levels of catch quality, together with working efficiency, was foremost in the owners’ minds from the very beginning of the project.

Prawns are initially moved forward from the reception hopper on the quarter by a catch-conveyor positioned towards the vessel’s centreline, before being transferred to a large rectangular sorting table arranged at 90° to the starboard rail. A dedicated and self-contained prawn packing area, which is also chilled and insulated, is located amidships, abaft the adjoining the blast freezer room, from which boxes of frozen prawns are lowered to the freezer hold.

All machinery for the freezing plants is arranged at main deck level in a forward compressor room, in close proximity to the areas they serve, thereby eliminating the need for any runs of pipes or cables. This compressor room is accessed from the forward chandlery store, located forward across the bow, in which a fire pump and harbour genset are also housed. A steam washer, serving several connection points throughout the vessel to ensure maximum levels of hygiene, is also situated in the forepeak.

A Geneglace ice machine is located in a separate compartment port side forward.

The accommodation casing lines the portside of the hull over the middle 2/3 of the trawler’s length and extends across almost to the vessel’s centreline.

The mid-section of the deckhouse, which also includes a crew protective gear storage area, gives access to the internal passages and companionways, large shower/WC compartment and separate laundry room. A twin-berth skipper’s cabin is located aft, while a well-equipped galley and spacious messdeck is housed in the forward section.

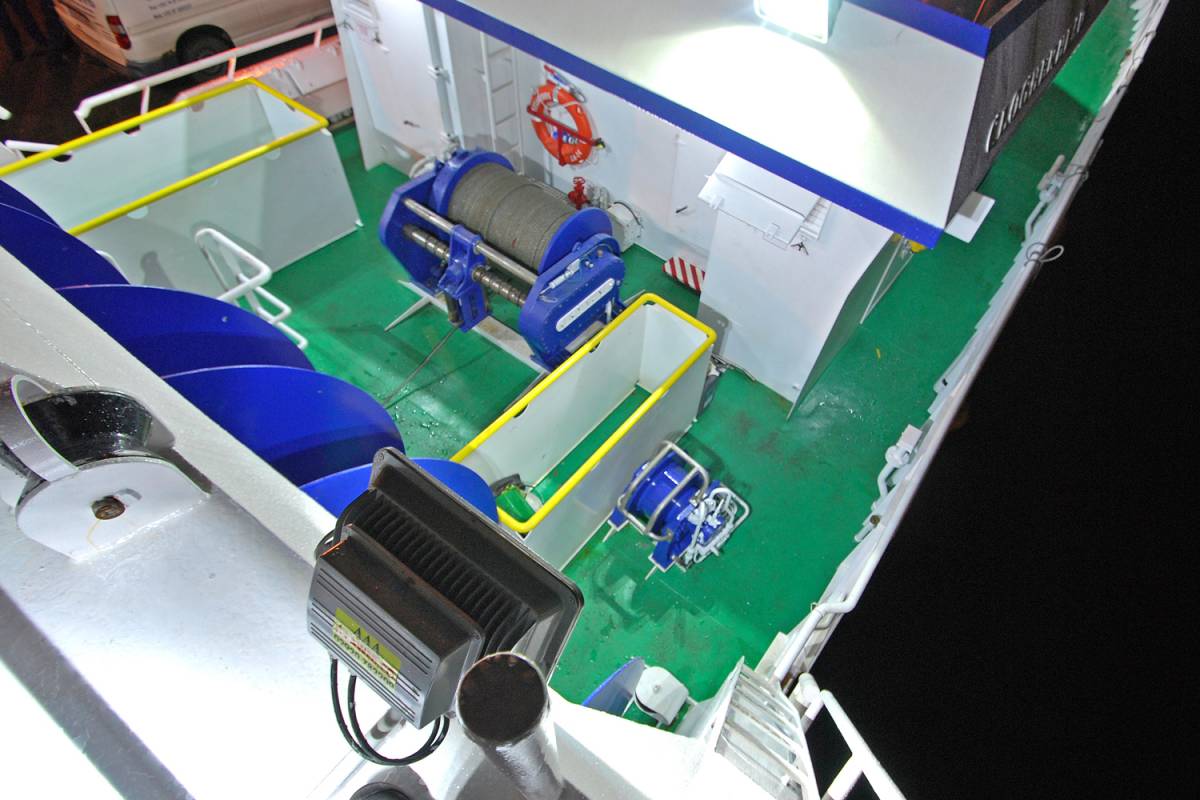

A key item of equipment on the main deck is a 2t auxiliary winch. Mounted just inside the forepeak bulkhead, the auxiliary winch enables the crew to pull torn nets forward along the full length of the main deck for repair.

Looking forward along the centreline of the main deck, along which torn trawls can be pulled the full-length for repair.

One of the two 4-berth cabins arranged forward of the full-width steering gear compartment across the transom on Audacious.

In accordance with David and Niall Kirwan’s requirement for a traditional wooden deck, the main deck features 4in x 2in boards of iroko. The mouthed hardwood planks were bolted to stud-welded bolts on the steel deck before being filled with pitch and then sanded and coated with linseed oil for a traditional finish. The main deck is flush, as is the hatch for taking out the catch, which can only be opened while in the harbour.

Below main deck level, the layout of Audacious from forward consists of forepeak, refrigerated fishroom (40m.), freezer hold (100m.), engineroom and the main sleeping quarters, which comprise two fourth-berth cabins arranged down the aft stair. The accommodation cabins are positioned forward of a separate full-width compartment across the transom that serves as an additional storage area, as well as giving full access to the Scan steering gear.

All internal areas throughout Audacious are finished to a very high standard. Light-coloured oak laminates and matching solid door/drawer fronts, together with stainless steel splashbacks, have been used to enhance the spacious feel created by a well thought-out arrangement that will also deliver durability and ease of maintenance in years to come.

Prawn trawling arrangements on Audacious are centred on three spilt-trawl winches and six net drums positioned towards the stern of the vessel.

EK Marine of Killybegs manufactured the full deck machinery package fitted on Audacious, in addition to designing the trawler’s load-sensing hydraulic system.

The 15t split trawl winches, which are spooled with 1600m of 20mm-diameter compacted German wire, are mounted on either side of the quarter. Positioned at 30° to the sides of the hull, the winches give direct leads to hanging blocks mounted at the end of the overhanging shelterdeck.

The third split-winch, serving the middle wires, is mounted on the shelterdeck abaft the wheelhouse, to give a direct lead to a sheave roller centrally mounted above the secure clump box incorporated into the transom. The middle winch also doubles up as an anchor winch.

Supplied by Swan Net-Gundry, and spread by a set of Thyboron Type 11 trawl doors (72-inch), the twin- and quad-rig prawn trawls are worked from a bank of six net drums mounted across the end of the shelterdeck underneath the trawl gantry.

Audacious is equipped with two full sets of quad-rig prawn trawls and one set of double bag twin-rig prawn trawls, together with three nets. One set of the 18-fathom quad-trawls are rigged on chain for use on clean ground. The second set of multi-rig nets are on 2in and 4in-disc rubber legs. Similar ground gear is used for the 26-fathom double bag twin-rig prawn trawls.

The two outer net drums are single 12.5t units. The inner net drums are 2 x 12.5t units, the centre flange of which can be unbolted and pushed across to one side to accommodate bigger trawls.

Catches are taken aboard towards the starboard side of the transom, using a 12.5t Gilson winch positioned on the shelterdeck forward of the trawl gantry.

Hardwearing 30mm nylon sheathing panels and strips are secured to outer hull areas in line with where the trawl doors and middle clump are worked, to minimise abrasion, wear and paint discolouration.

The engineroom on Audacious is particularly spacious and well laid out, illustrating the detailed thinking David and Niall Kirwin put into the layout, in close collaboration with Ove Kristensen and the Mooney Boats team, in order to ensure efficient maintenance in the future.

In order to provide the maximum amount of clear space in the engineroom, the main electrical switch boards, along with the hydraulic valves, are installed in a dedicated compartment on the starboard side of the main deck aft of the prawn-sorting table. With only five hydraulic pipes leaving the engineroom, this arrangement facilitated a very simple and efficient installation.

Padmos of Killybegs supplied the four Mitsubishi engines.

The Mitsubishi S6R2-T2MPTK-3 Tier II-compliant main engine develops 395kW @ 1350rpm and is coupled to a Reintjes WAF 474L 7.476:1 reduction gearbox to turn a 2500mm-diameter fixed pitch propeller in a high efficiency nozzle. This combination results in a maximum propeller speed of 180rpm, and one of around 140rpm when typically towing with the main engine running at 1050rpm.

On fishing trials in the Irish Sea from Clogherhead, Audacious towed the prawn gear across the tide at 3 -3.2 knots when the main engine was running at 950rpm and using a highly economical 52 litres of fuel per hour.

A Stamford 81 kVA shaft generator is belt-driven off the front end of the main engine. This optimises the vessel’s electrical needs when steaming, and reduces fuel consumption by eliminating the need to run any of the auxiliary engines.

A Mitsubishi S6B3-T2MPTAW-15 auxiliary engine (335kW @ 1500rpm) mounted on a steel frame atop the starboard tank powers the deck machinery hydraulics through a Technodrive gearbox that drives three Parker PV240 load-sensing hydraulic pumps. The Technodrive gearbox is fitted with an air flex coupling between engine and gearbox, which allows the crew to operate the clutch from the wheelhouse trawl console. A secondary Stamford 140kVA alternator is driven off the for’ard end of this auxiliary engine.

A back-up hydraulic gear retrieval system is provided by a 45kW 50Hz electric motor, driving a Parker PV 063 load-sensing pump.

The main electrical power auxiliary engine on Audacious is a Mitsubishi 6D16-T (128kW @ 1500rpm) driving a Stamford 140 kVA. Also fitted with a wheelhouse start/stop panel, this engine can be used as a backup to the boat’s load power when required.

Cooling for the main and auxiliary engines is through box coolers positioned at the fore end of the engineroom. Three Cleghorn Warning bronze self-priming AM 50 pumps, performing bilge, deck wash pump and emergency firefighting duties, are mounted on a dedicated platform located alongside the main sea valve chest. A fourth AM50 unit, used as the fire pump, is housed in the forepeak on the maindeck. Two Cleghorn Waring AM 40 pumps are also fitted to serve the refrigeration and hydraulic cooling systems.

A waste oil tank is located below the engineroom floor, with all drip trays and sumps from the main and two auxiliary engines piped to this tank, which is emptied using a 1.” Jabsco pump and a discharge valve on the main deck. Engineroom cooling is provided by a three-phase, two-speed stainless steel fan.

A 30kVA Whisper harbour genset based on an air-cooled Mitsubishi S4S is fitted in the forepeak and is used to power the vessel while in harbour. This generator is also used to run the emergency fire pump on the vessel and emergency power supply.

A hydraulically-powered Hundested bow thruster of 120kW is fitted to give maximum vessel manoeuvrability in restricted areas.

Fuel capacity is 30,000 litres, equally distributed between two engineroom wing tanks and a bottom tanks under the concrete floor of the freezer hold. 18,000 litres of freshwater are carried in the bulbous bow and a double bottom tank under the fishroom.

Pat Maguire of Galway supplied, installed and commissioned the extensive array of electronic equipment, information from which is displayed on flat screens flush-mounted in the main forward console.

Details of the trawler’s location are processed by Furuno GP32 GPS and Koden KGP 920 wheel-marked receivers, and heading is provided by a Furuno SC50 satellite compass. Positioning data received is interfaced to three Sodena plotting systems supporting a combination of tidal data, CMAP charts, AIS and ARPA tracking.

Both the Koden MDC 2910 and 2041 radars are interfaced to a Koden KAT 100 Class A AIS transceiver and, with ARPA, provide tracking both within the radars themselves as well as the plotting systems.

Steering and navigation is taken care of by a Simrad AP70 digital autopilot.

Bottom-sounding and fish detection duties onboard Audacious are handled by two Furuno FCV295 dual-frequency (50/200kHz/28/75kHz) colour sounders.

Communications and safety equipment includes Sailor 6310 MF/HF GMDSS and Furuno FS-1562-15 radio telephones, Sailor 6222 DSC and Icom ICM423 VHFs, 2 x Icom handheld GMDSS VHFs and a Furuno NX 300 Navtex.

Audacious builds on Courageous start

David and Niall Kirwan bought their first boat Courageous from Lossiemouth skipper Alec Flett in 1998.

David and Niall Kirwan first went into partnership in 1998, when they bought the former Peterhead-based pair-seiner Courageous II INS 146 from Lossiemouth whitefish skipper Alex Flett.

Before leaving Scotland, Courageous II was modified at Macduff for twin-rig trawling, before fishing prawns off the east and west coasts of Ireland.

Courageous II was built in 1973 as Opportune BCK 105 for Buckie skipper George Murray, when the open-decked seine-netter was the third of the highly successful Campbeltown 80s to be built at Campbeltown Shipyard. Later fitted with a gutting shelter, Opportune was renamed Steadfast II KY 241 on being bought by Alex Gardner of Ansthruther in 1982. Five years later Steadfast II was renamed Courageous II INS 146 by skipper Alex Flett. In 1989 Courageous II’s cruiser stern was converted into a transom stern, at the same time as a three-quarter length shelterdeck was fitted by Richards of Lowestoft, then converted for twin-rig trawling.

In 2005 the brothers went to Boulogne to purchase their second boat, the 22.4m French trawler Vox de L’Etaplosis II BL-644529, which was subsequently renamed Ambitious DA 62. Declan Clinton, who is now skippering Audacious, joined David and Niall Kirwan’s partnership, as skipper of Ambitious, which is currently being re-engined with a new Mitsubishi prolusion unit prior to being sold.

Two years later, the 23.4m Le Grand Louis AD-584767 was renamed Virtuous DA 80 after being bought by David and Niall Kirwan. The following year, Virtuous was joined by her sistership Marie Josephe AD-584850, which was renamed Courageous DA 18 following the decommissioning of the original Courageous. Virtuous is now skippered by Mark Francis, while Robert Byrne is in the wheelhouse of Courageous.

All the prawns from the three boats are sold directly by David Kirwan to well-established customers in Europe. This personal level of service, which also includes an in-house transport system, ensures that David Kirwan is in constant contact with his clients at all times and is therefore able to offer a bespoke service in line with their exact requirements.

GEA Refrigeration systems

The separate self-contained blast freezing compartment, freezer and refrigerated storage holds on Audacious are fitted with customised chilling systems, supplied and installed by GEA Refrigeration Ltd of Co Cavan.

The blast freezer equipment consists of a purpose-built GEA 15kW evaporator served by three 3-phase 400-volt, 50Hz fans incorporating copper coils, epoxy-coated fins and stainless steel casings. Served by a Bitzer seawater cooled condensing unit and Bitzer Ecoline compressor, this blast freezing system is designed to deliver a temperature of -28°C.

This high level of specification enables up to 700kg of prawns to be blast-frozen from +15°C to -25°C in approximately five hours, before being transferred to the freezer hold.

The freezer hold is served by a second custom-designed GEA evaporator. Of similar construction as the blast freezer unit, the 7kW freezer hold system is also operated by a Bitzer sea-water cooled condensing unit and Bitzer Ecoline compressor, to maintain a storage temperature of -20°C for the duration of a trip.

Bitzer machinery, in addition to a Danfoss water pressure regulating valve, is also employed to provide a temperature of -1°C in the forward refrigerated fishroom, which is fitted with 18mm-diameter stainless steel piping on the deckhead.

The refrigeration systems are also fitted with a Dixell temperature monitoring and logging system, so the crew can track the performance at all times.

A Geneglace F30M flake-ice machine, producing 1t per 24 hours, is also fitted. Supplied by Capital Refrigeration and installed by Mooney Boats, the Geneglace machine is housed in a dedicated compartment forward on the portside of the main deck and is supplied from a 14,000-litre bulbous bow tank.

Working arrangements

A stainless steel hoist is used to deliver cartons of frozen prawns from the blast freezer down to the freezer hold.

Catches are taken in over the stern of Audacious to an aluminium hopper positioned towards the starboard side. After the codends are emptied, the aft side of the reception hopper is tilted forward using the Gilson winch, before being securely supported by deck-mounted legs while it is emptied. From the reception hopper, prawns run forward to an elevated conveyor belt before being carried forward, to starboard of the vessel’s centreline, to the sorting table for selection.

In order to save deck space at this location, two stainless steel prawn washers are mounted on a sliding arm under the sorting table, enabling them to be pulled out for use as required. The catch-handling system was fabricated by DCI Stainless, in conjunction with Mooney Boats.

Washed prawns are subsequently taken forward into the packing room, where they are put into the refrigerated dip tank before been finger-packed into their cartons. Filled cartons of prawns are then moved forward again into the adjoining blast freezer room where they are placed on racks.

After the product is frozen, it is then lowered to the cold store below main deck using a stainless steel lift fabricated by Mooney Boats.

There is a minimum depth of 300mm closed-cell foam insulation on all areas of the freezer and refrigerated fishrooms, together with the blast freezer room, on Audacious.

Once insulated, the areas were lined by the yard using pre-fibre-glassed marine plywood fastened onto treated timber grounds with stainless steel screws. On completion of this work G Smyth Boats of Kilkeel was engaged to complete the fibreglass, and gelcoat all exposed surfaces.

EK Marine Ltd

EK Marine supplied the full deck machinery package fitted on Audacious, including the six 12.5t net drums positioned under the trawl gantry aft on the shelterdeck.

EK Marine Ltd was awarded the contract to design, manufacture, install and commission the deck equipment and load-sensing hydraulic control system for Audacious.

Having used EK Marine Ltd for the past 10 years, to install and maintain the deck machinery on Ambitious, Courageous and Virtuous, the Killybegs company was David and Niall Kirwan’s first choice for the complete Audacious hydraulic package.

This includes:

- 3 x EKM 15t split trawl winches with level wind and a drum capacity of 750 fathoms of 20mm wire

- 2 x EKM split net drums 2 x 12.5t

- 2 x EKM single split net drums 12.5t

- 1 x EKM 5 Gilson winch with drum capacity of 100m of 20mm wire

- 1 x EKM 500kg electric hoisting winch

- 1 x EKM 2t dragging winch

- 1 x EKM 8m fixed-boom landing crane capable of 360° slewing, equipped with 1t two-speed winch and deck-mounted local controls

- Load-sensing hydraulic system including wheelhouse control system with two-speed directional controls for the winches and net drums, plus the bow thruster, and incorporating an EKM wire-length monitoring computer.

The contract to manufacture and install the Audacious package came in quick succession to Eunan Kennedy’s team at Killybegs supplying comparable full systems to Patrick C DA 77, Carmarose, SO 555, Colmcille G 185 and Westward Isle G 186, as EK Marine Ltd consolidates its position as the leading deck equipment manufacturer for Irish fleet new-builds, at the same time as working towards further expanding its customer base.

Audacious DA 14

DETAILS

Owners: David and Niall Kirwan, Clogherhead, Co Louth, Ireland

Designer: Ove Kristensen, Vestværftet ApS, Hvide Sande, Denmark Boatyard: Mooney Boats Ltd, Killybegs, Ireland

DIMENSIONS and CAPACITIES

Length overall: 25.6m; Length reg: 23.5m; Beam: 7.5m; Depth moulded: 4.4m (maindeck); Draft: 4.6m; Tonnage: 230tonnes gross; Fuel: 30,000 litres; Fresh water: 18,000 litres; Lube oil: 450 litres; Hydraulic oil: 2,100 litres; Fishroom: 40m.; Blast freezer:15m.; Freezer hold: 100m.

ENGINEROOM

Main engine: Mitsubishi S6RT2MPTK-3 of 395kW @ 1350rpm driving through a Reintjes WAF 474L 7.476:1 reduction gearbox to a 2500mm-diameter four-bladed propeller/high efficiency nozzle. Speed: 10 knots Auxiliary engines: Mitsubishi S6B3-T2MPTAW-15 of 335kW @ 1500rpm driving deck machinery hydraulics through a remotely-clutched Technodrive gearbox and a 140kVA Stamford 415/3/50 alternator; Mitsubishi 6D16-T of 128kW @ 1500rpm driving a 140kVA Stamford 415/3/50 alternator; Mitsubishi S4S 30kVA Whisper harbour genset Bow thruster: Hundested hydraulically-driven 120kW Fuel and oil filters: CC Jensen Bilge, deck wash, fire fighting, refrigeration and hydraulic cooling pumps: 4 x Cleghorn Waring AM50 and 2 x Cleghorn Waring AM 40 electrically-driven

DECK MACHINERY

Supplier: EK Marine Ltd, Killybegs

3 x EKM split trawl winches 15t; 2 x EKM split net drums 2 x 12.5t; 2 x EKM single net drums 12.5t; EKM gilson winch 12.5t; EKM 8-1-390C landing/deck crane; 2t auxiliary trawl handling winch

CATCH HANDLING and STORAGE

Catch handling system: DCI Stainless, Drogheda, Co Louth and Mooney Boats Ltd, Killybegs; Fishroom chilling/freezing: GEA Refrigeration Ltd, Co Cavan; Ice Machine: Geneglace F30M Capital Refrigeration, Ireland

ELECTRONICS

Supplier: Maguire Marine Electronics Ltd, Co Galway

Fish detection: 2 x Furuno FCV 295 dual-frequency (50/200kHz and 28/75kHz colour echosounders; Scanmar net monitoring system

Navigation: Koden MDC 2910 and Koden MDC 2041 radars; Furuno GP-32 GPS and Koden KGP 920 wheel-marked receivers; 3 x Sodena plotters; Simard AP70 autopilot; Koden KAT 100 AIS; Furuno SC 50 satellite compass

Communications: Sailor 6310 150W GMDSS HF SSB and Furuno FS-1562-15 radio telephones; Sailor 6222 DSC and Icom ICM423 VHFs; 2 x Icom handheld GMDSS VHFs; Furuno NX 300 Navtext, McMurdo G5 EPRIB; McMurdo SART; Intellian Satellite system; 4-camera CCTV system with 4-way switcher

FISHING GEAR

Supplier: Swan Net-Gundry, Killybegs, Co Donegal – Nets: 5 x 18-fathom clean ground quad-rig prawn trawls; 5 x 18-fathom 2in-4in rubber-leg quad-rig prawn trawls; 3 x 26-fathom double bag 2in-4in rubber-leg twin-rig prawn trawls; Doors: Thyboron Type 11 72-inch; Wire: 2 x 1600m of 20mm-diameter compacted German wire

ACCOMMODATION

1 x 2-berth skipper’s and 2 x 4-berth cabins

GENERAL

Engine controls: Kobelt Electronic 3 station; Insurance: D & D Insurances Ltd, Dublin

Lifesaving appliances: Marine Suppliers, Howth; Mooney Boats Ltd and Swan Net-Gundry, Killybegs; Paint: Jotun; Steering: Scan 1000; Wheelhouse seats: Gramma Kingman

Read more from Fishing News here.