Automated catch handling systems

Golden Shore is equipped with dedicated king scallops and queenie catch handling systems that are designed to deliver optimum levels of catch quality while also considerably reducing the crew’s workload.

When fishing king scallops, the contents of the dredges are released into stainless steel reception hoppers fitted along the port and starboard sides. On shooting back the gear, heavy-duty conveyor belts move the catch aft towards crewmen for selection. Filled baskets of scallops are then delivered via a chute down into a vertical storage aluminium hopper positioned towards the stern of the fishroom, from where they are later retrieved for bagging.

After the queenie trawl is hauled onto the elevated 10t net drum, fabricated by the yard with aluminium side flanges, the codend is lifted aboard using the starboard topping Gilson, before the contents are released into a large stainless steel hopper. This is located aft of the lifting gantry in place of the easily removable starboard scallop conveyor which can be quickly unbolted and lifted ashore.

Looking aft along the portside scallop hopper and conveyor.

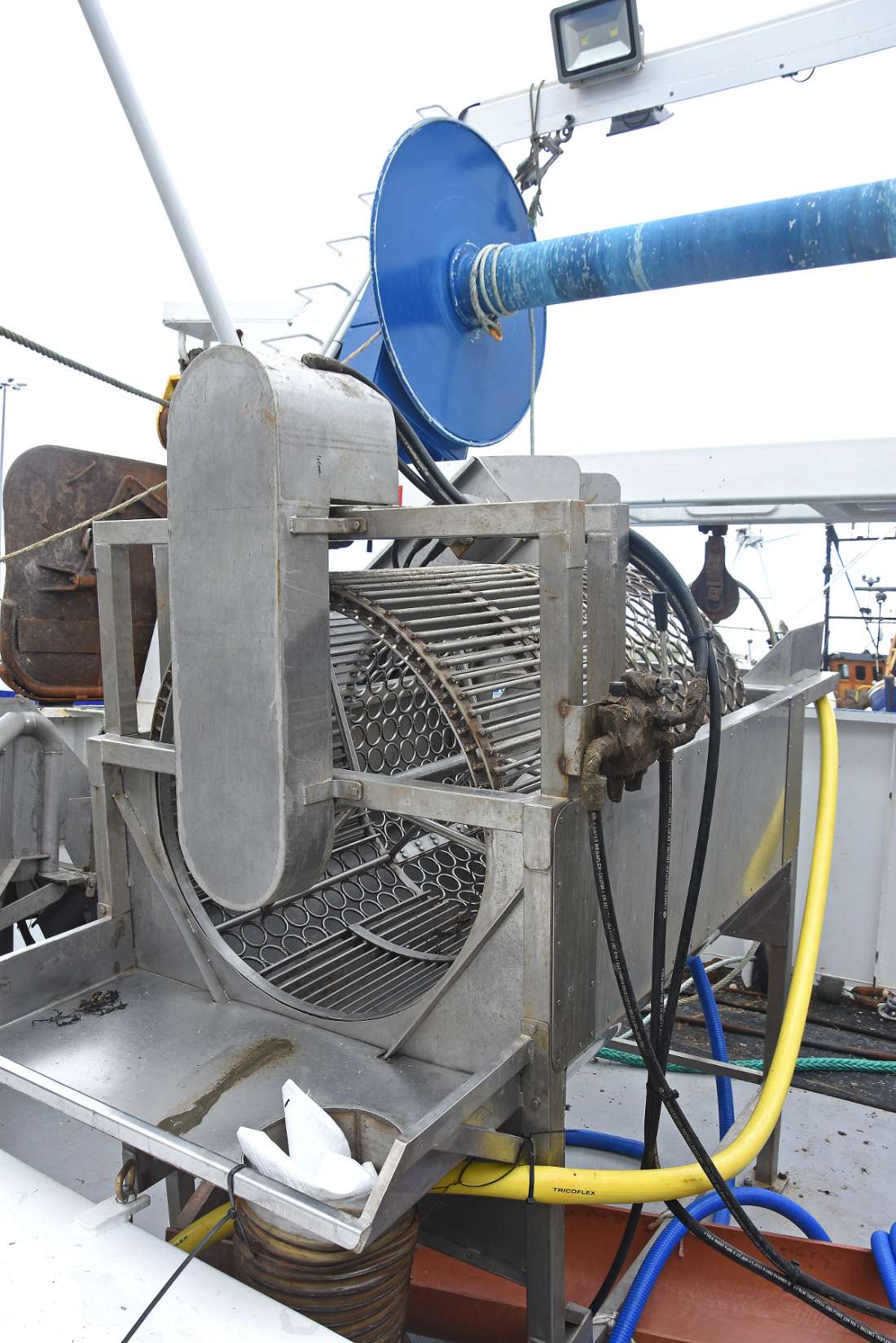

With a capacity for an estimated 50 bags, the after end of the queenie hopper is secured to the main deck via a pivoting mounting system. When the codend is released and taken aft again, the wire from the starboard topping Gilson is clipped on to the foreside of the hopper, enabling it to be gradually lifted up. This in turn allows the contents to flow aft onto an elevated hopper, which effectively picks them up from almost deck level, for delivery into a hydraulically-driven stainless steel queenie riddle located on the vessel’s centreline.

From the riddle, selected queenies are delivered to an aluminium storage hopper in the fishroom, while small queenies are returned to the seabed by a plastic chute leading across the deck towards the aft scupper on the portside.

Queenies are delivered onto an elevated conveyor by gradually raising the fore end of the trawl reception hopper…

While in some ways this queenie catch handling system is similar to the one the owners used on their previous boat Lynn Marie, the one main difference is that queenies descend freely onto the conveyor, rather than being lifted out of the hopper by the conveyor. This change is expected to considerably extend the life of the rubber conveyor belts, by reducing the amount of weight and abrasion on them.

The stainless steel side conveyors and the queenie riddle system were custom-designed and manufactured by Joe Lynch of Greencastle, Co Donegal.

… before entering a hydraulically-driven stainless steel riddle…

Approximately 400 x 40kg bags of king/queen scallops can be arranged in Golden Shore’s large fishroom, which is 5.5m long and 2.5m high.

… from which selected shells descend via a chute to a hopper in the fishroom for bagging.

The fishroom sides and deck head were sprayed with insulation to a minimum thickness of 150mm and lined with ¾-inch marine plywood. On completion of this work, all exterior surfaces were fibre-glassed and gel coated. Two2t ice lockers are positioned aft on either side of the hatch leading to the steering gear compartment. Stainless steel refrigeration pipes are fitted to the underside of the deckhead. The fishroom refrigeration system is served by Blitzer compressor and a K073HB condenser units supplied by Cool Temp, which commissioned the system after it was installed by the yard.

Aluminium tread plate lift up panels arranged along the centreline give direct access to the shaft and bilge.

Kilkeel company supply wheelhouse electronics

Golden Shore’s electronic wheelhouse equipment was supplied, installed and commissioned by SIRM UK of Kilkeel (previously Selex ES). Centrally positioned on top of the steel deckhouse and whaleback, the aluminium wheelhouse provides a commanding all-round view.

Accessed from the starboard side, the customised interior features an extremely high quality of craftsmanship. The skipper’s NorSap 1500 seat is offset towards the portside, where it is flanked by wing and central consoles, ensuring that all controls for the electronic equipment are within easy reach.

Golden Shore’s wheelhouse electronics equipment was supplied and installed by SIRM UK of Kilkeel.

Five 17in AG Neovo TFT screens are flush-mounted in the full-width forward console to provide skipper Chambers with a constant display of information on the seabed configuration relative to the scalloper’s location.

The importance of accurate vessel positioning relative to the selected, and usually small-scale, scallop grounds fished, is shown by the presence of an Olex 3D dual-screen seabed mapping and Trax Fishpro 6 plotting systems.

Details of the vessel’s location are processed by a Furuno GP32 GPS receiver and heading provided a JRC JLR-21 GPS compass. Bottom sounding is handled by a Hondex HE-7300 singlefrequency (50kHz) colour sounder.

The JRC JMA-5212 10kw radar is fitted with ARPA and AIS interfaces to provide tracking both through the radar display as well as the plotter. Steering and navigation is taken care of by a Navitron NT921 digital autopilot. A joystick control is positioned on the central island console, where the EC300 Power Commander electronic engine controls are also fitted.

Communications equipment installed on Golden Shore Icom IC-M323 DSC and Sailor 6210 VHFs, Sailor Fleet One sat-phone and Intellian I4P SAT TV.

Determination and experience overcome adversity

Golden Shore replaces the owners’ previous boat; the 17m wooden-hulled Lynn Marie N 264, which left Kilkeel last month for Peel after being bought by Billy Caley.

Recently sold to the Isle of Man, Lynn Marie…

Skipper Geoffrey Chambers bought Lynn Marie from Buckie in 2009, when the boat was rigged for scallop dredging in a large-scale conversion, to replace his previous command, the 17m Alexander Noble-built Prospector N 1 (ex BA 25, TT 24), which was sold to Jersey. Eighteen months later, Lynn Marie was badly damaged while on her way to scallop grounds south east of the Isle of Man when the scalloper was hit by the 155m container ship Philipp, which was on passage from Liverpool to Greenock in the Clyde and steaming at 16 knots. (Fishing News, 15 April 2011).

The severity of the impact resulted in the bow of Lynn Marie being knocked clean out by the weight and momentum of the 8971 GT container ship.

… replaced Geoffrey Chambers’ previous boat Prospector in 2009. (Photograph courtesy of Darren Purves).

After being safety escorted back to Port St Mary in a major rescue operation, Lynn Marie later berthed in Macduff harbour. On removal of all the damaged hull sections, a highly experienced team of four shipwrights from Macduff Shipyards fashioned and fitted a new oak apron, stem post, forward frame and 15 new hull planks, together with nine new deck stanchions, three steel deck beams, full forward decking, topside planking and gunwale rails in less than three months.

Lynn Marie BCK 86 was built by Herd & Mackenzie in 1973, for a local partnership headed by William Wilson, and fished from Buckie for 37 years while owned by the same family before being sold to Kilkeel.

Biblical connection to 153

Golden Shore’s PLN of N 153 was the number of Geoffrey Chamber’s great uncle’s first boat John Chambers N 153, which he was pleased to be allocated when he applied for it for the new family boat.

The significance of the number 153 centres around the New Testament reference to the miraculous draught or catch of fishes (John 21:1 – 11), when Peter, together with some other disciples, had fished all night for nothing in the Sea of Galilee.

In the morning, a man on the shore (they did not know it was Jesus) shouted to them to cast their net to starboard, as a result of which 153 great fish were dragged to the shore.