The number of new over 15m boats currently on order is at the highest level since the millennium. In the next two years, nearly 20 new bespoke builds are scheduled to join the UK fleet. This number of new boats is expected to rise by around 25% when a number of further orders, now at an advanced stage of discussion, are expected to be confirmed in coming months. David Linkie reports

Above: The 27.7m, pair-seiner Rosebloom is one of nearly 20 new-builds at varying stages of construction or order for owners in Scotland.

The level of current investment in any industry has always been recognised as a strong indicator of its long-term future. Therefore, the fact that some £200m is currently being invested to build state-of-the-art new vessels, that will enable skippers and their crews to catch their annual quotas with enhanced safety, efficiency and financial viability, is a very positive and welcome sign.

Although the benefits associated with purpose-built vessels are well-known, the number of new additions in recent years has usually been counted on the fingers of one hand, as the already high average age of the UK fleet – 33 years – continues to rise.

So what significant factors, if any, have changed in the past 18 months when the first orders for the boats now under construction were placed?

In many respects, the answer is probably ‘not very many’, apart from a favourable Sterling/DK Kroner exchange rate reaching its zenith a few months ago.

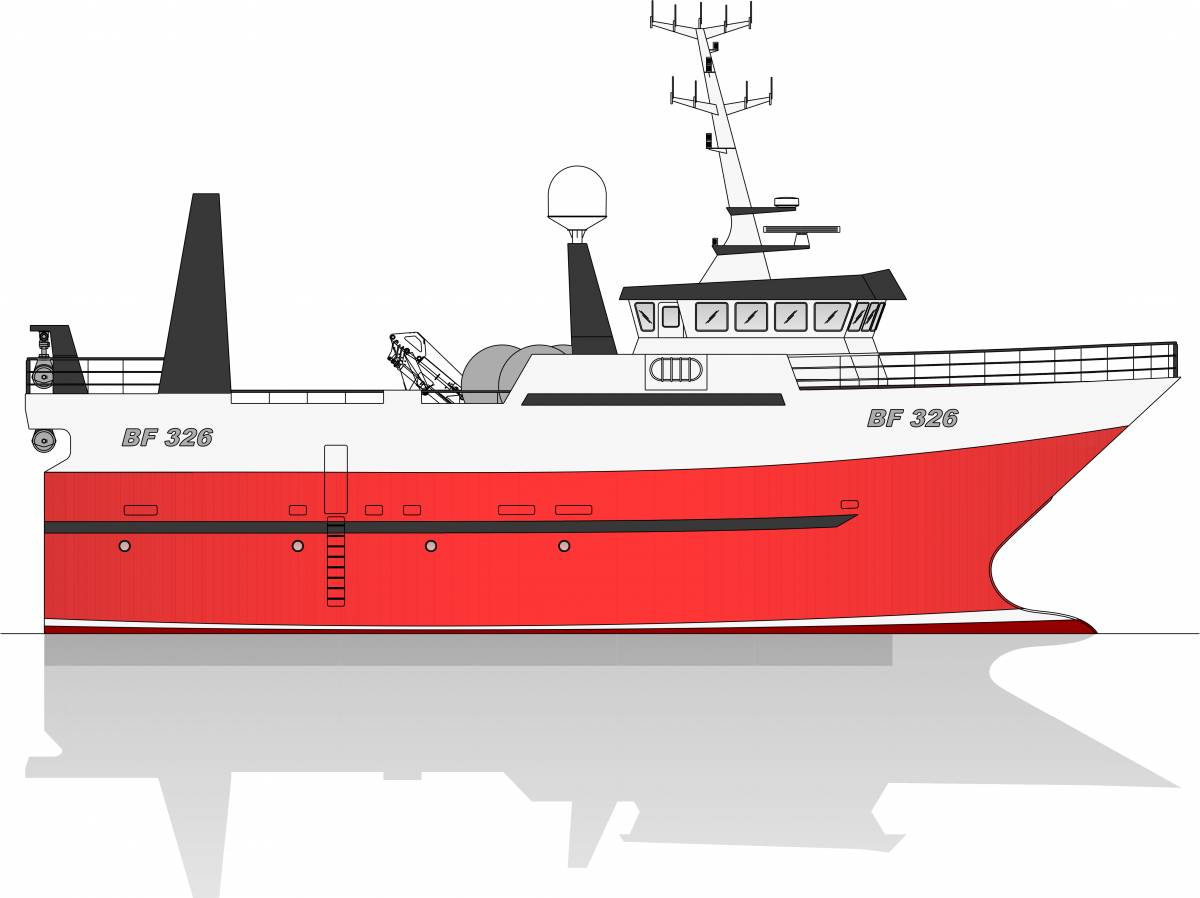

One of the five new pelagic vessels scheduled for delivery to Scottish partnerships in the next 18 months.

For some years now, the level of demersal and pelagic stocks has been steadily increasing as the raft of technical and spatial measures, which fishermen endured considerable short-term pain to implement, quickly proved highly effective, and brought impressive results in a rapid timescale.

During this time, on a daily basis, whitefish and pelagic skippers have consistently reported a steadily increasing abundance of fish on the grounds. There is little doubt that had these encouraging signs been seen up until 20 years ago – when stock levels were the main criteria to be taken into consideration when placing new boat orders – they would have triggered a sustained flow of orders for new builds.

However, the march of time inevitably changed the situation, as a result of which, caution became a necessary criterium. Primarily, this was because of the uncertainty and lack of predictability that prevailed in top-down fisheries management, threatening to strangle what previously had been widely viewed as the lifeblood of the fishing industry going forward – investment in purpose-built new vessels.

A number of highly determined, strongly motivated younger skippers, who were already committed to the long-term future of the industry. These were represented on one side of the coin, the other face of which depicted unknown issues; fishing opportunities, access to quota and the implications of the looming landing obligation, all of which presented unknowns in terms of future business stability in years to come, and economic viability.

This contrasting situation represented a peculiar dilemma.

One of the reasons why the positive side of the coin, directly associated with the increase in stock levels – now beginning to be recognised by scientists – is prevailing today, can probably be traced back to the high oil prices of a few years ago, when the impact of fuel costs on a boat’s bottom-line expenses became a major concern for skippers and their crews.

Acutely aware of the impact this was having on their economic viability, hull form, propulsion efficiency and fuel economy became of increasing interest to skippers, naval architects and boatyards alike.

While new boats have always been associated with reduced expenses, incurring minimal maintenance costs in their initial years of service, the levels of fishing efficiency and savings generated by vessels incorporating new hull and centreline propulsion technology have moved up by several levels.

In doing so, this has added a significant factor to the positive side of the coin.

The successful economic performance delivered by the small number of new builds in recent years, including Benarkle II, Guardian Angell and Boy John, subsequently provided further positives.

These benefits gave further confirmation to what skippers already knew; that purpose-built new boats offered better long-term prospects than a boat that was perhaps already 20-30 years old. By this age, they require high levels of maintenance if they are to be kept for another 10-15 years, during which time skippers are continually on the back foot compared to colleagues who opt to go down the route of new-builds.

Benarkle II…

Guardian Angell…

… and Boy John are among the recent purpose-built new boats delivering optimum levels of fishing efficiency and fuel economy.

The new boats now on order are all designed to enable their owners to catch their existing allocation of annual quotas with optimum levels of catch quality, fishing efficiency, operational economy and crew safety, for years to come.

That the 17 new builds summarised in this overview feature are being built to replace vessels with a combined age of 317, serves as a timely reminder of the importance of the new tonnage.

By representing a strong statement of confidence in the future of the fishing industry, and one that is clearly fully endorsed by bank managers, the investment in new boats also provides a strong message of encouragement for young fishermen just starting out on their careers.

That experienced, but still young, skippers see a sustainable future in fishing, that will provide secure career prospects for new entrants, delivers an extremely important message.

On a similar theme, the boats due for replacement during the next 24-36 months will provide other skippers with the opportunity to replace their current boats. In recent years, the level of boat sales in the UK fleet has probably been at an all-time low, largely due to the shortage of orders for new-builds. Already, the imminent arrival of new vessels has begun to stimulate activity in second-hand boat sales. Given that these are also well recognised as being a barometer of a viable industry, this represents further positive news.

The new-builds also send the highly positive message to consumers of fish, throughout Britain and further afield, that the catching sector views current stock levels as being sustainable, and justifies investments of over £200m.

It should also be recognised that the new boats now on order will provide valuable employment, not only at boatyards, but also for the wide range of service companies that will be involved in the manufacture and supply of new machinery and equipment to each vessel.

It is particularly pleasing that the boats now on order include a general mix of fly-shooters, scallopers/single/twin-rig trawlers and pelagic vessels, ownership of which is also spread across a similarly broad geographical base.

Three Rs lead the way

Vestværftet will complete Rosebloom in the next two months, when the pair-seiner will start fishing with her sistership Boy John.

Although different types of vessel, the first three new-builds scheduled for completion in the next few months share one common characteristic, in that their names each begin with the letter R – Rosebloom, Rebecca and Resilient.

Fit-out of the new 27.7m, versatile, whitefish vessel Rosebloom INS 353 at Hvide Sande, Denmark, is now at an advanced stage of completion.

Designed for pair-seining and fly-shooting, the new vessel is being built for Avoch brothers Andrew, Donald, Johnny and Sandy McLeman, together with Denholm Fishselling Ltd. Rosebloom is a sistership to Boy John INS 110, which Vestværftet ApS handed over to its owners 14 months ago, since when the vessel has performed well, pair-seining with the previous Rosebloom.

The new Rosebloom has a registered length of 23.95m, 8.2m beam and a shelterdeck depth of 6.45m.

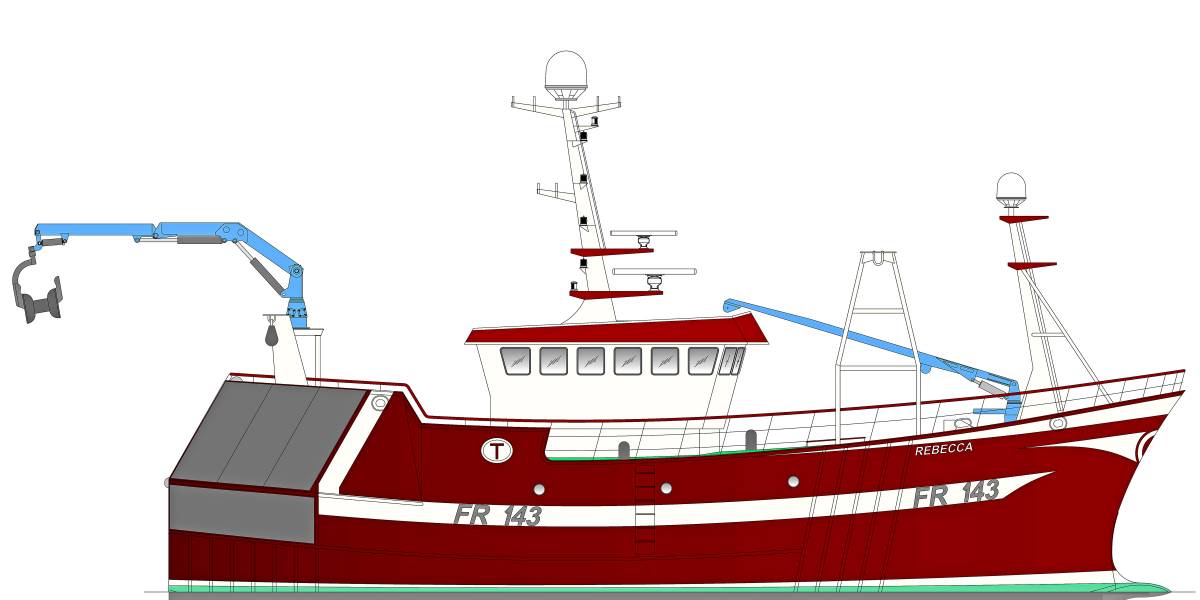

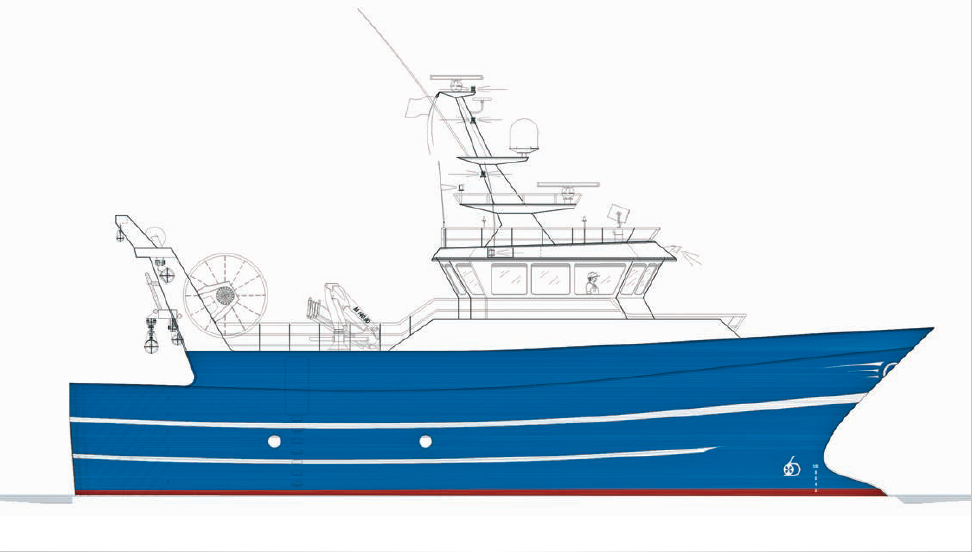

Profile of the new 24m Rebecca that Macduff Shipyards is building for a Fraserburgh family-partnership.

Fishing activities will be focused on two large-capacity 16t power reels, two split drums (2 x 10t) and 2 x 7.5t bagging winches manufactured by Kynde and Toft of Thyborøn. Catches will be bagged centrally over the transom using a 7t codend winch.

Like Boy John, Rosebloom will be powered by a Caterpillar 3508C main engine, Heimdal 9.4:1 reduction gearbox, and a matching Heimdal 2800mm-diameter CP propeller and nozzle.

Two Mitsubishi 6D16 auxiliary engines, driving 116kVA gensets, will also be housed in Rosebloom’s aft engineroom.

A new design of 23.95m twin-rig trawler for the Fraserburgh family-partnership of skippers Adam Tait and his sons Adam Jnr and Jonny Tait, is nearing an advanced stage of completion in Macduff Shipyards’ main fabrication hall.

With 7.40m of beam and a moulded depth of 4.20m, the underwater form of the double chine hull has been designed to provide a maximum smooth flow of water to a large propeller aperture, in order to deliver optimum levels of propulsion efficiency and fuel economy across all modes of operation.

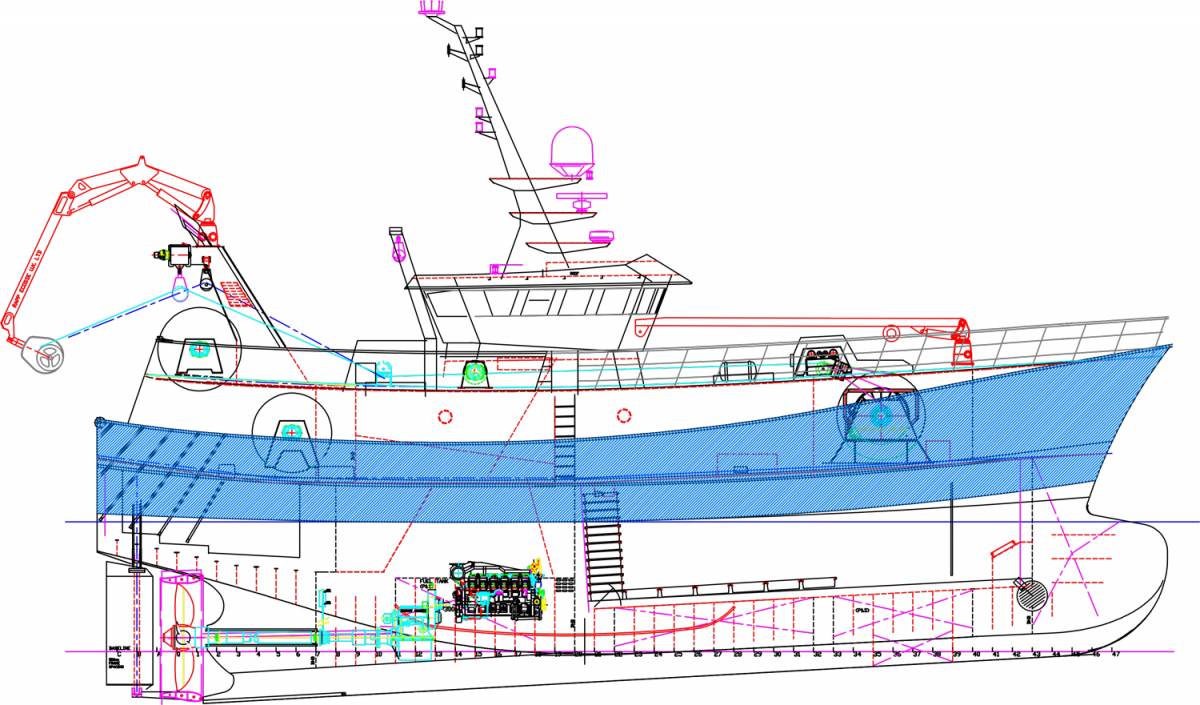

Fit-out work in progress on Rebecca in Macduff Shipyards’ main fabrication hall.

The centreline machinery for the new Rebecca includes a Caterpillar C32 main engine, Masson 9:1 reduction gearbox and a 2500mm-diameter propeller.

Three Cummins auxiliary engines, one hydraulic and two electrical, are also installed in the engineroom.

The main items of deck machinery have been manufactured by the boatyard, with the customary three-drum trawl winch, housed in a dedicated winch compartment forward of the main catch-handling area amidships.

At Whitby, Parkol Marine Engineering is now fitting-out a new class of 27m dual-purpose seiner/trawler, for the Resilient Fishing Company Ltd of Shetland.

Designed by Ian Paton of SC McAllister & Co Ltd, for Whalsay skipper Arthur Polson, together with partners Edward Jamieson, John Montgomery and John Irvine, the whitefish vessel is of round bilge hull form, with a registered length of 23.95m and 7.8m of beam.

Profile drawing of the 27m seiner/trawler being built at Whitby for the Resilient Fishing Company Ltd.

The Mitsubishi S12R-MPTAW main engine will drive a 2700mm-diameter Finnoy VP propeller, through a Finnoy G50 FKV 10.75:1 reduction gearbox.

Two Mitsubishi 6D16T auxiliary engines will also be fitted.

Thyborøn Skibs and Motor A/S (Three Js) of Thyborøn, has designed and manufactured an extensive package of customised deck machinery.

Two power reels, with a core pull rating of 20t and a capacity of 3900m of 40mm-diameter seine rope, are positioned forward on the main deck. When fly-shooting, the power reels will operate through a Scantrol iSYM system, and a Scantrol auto-trawl system when single-rig trawling. The ropes/wires will be spooled onto the power reels by electronically-controlled guiding-on gear, incorporated into framework that will be fitted across the full width of the shelterdeck, aft of the power reels and forward of the vessel’s wheelhouse.

In order to deliver optimum leads when hauling back the seine-net ropes, or towing a single boat trawl, the hanging blocks will be positioned hydraulically by a full-width modular unit, mounted on the main fishing gantry, aft. Two 2 x 8t split net drums will be positioned on the shelterdeck, together with a 14.5t unit for installation on the quarter.

Busy times for Macduff Shipyards

At the same time as Macduff Shipyards is constructing a 25.70m dredger for Aberdeenshire Council in its building hall at Buckie, and fitting-out the 24m Rebecca in its main fabrication hall at Macduff, the hulls of two other trawlers are currently being built under sub-contract at shipyards in Szczecin, Poland.

The Kedat Shipyard has almost completed fabrication of a new twin-rig trawler, ordered by skipper Andrew West and partners of Peterhead, for which the main dimensions are LOA 21.50m, beam 7.10m and a depth moulded 4.10m.

The centreline machinery for the new build will include a Caterpillar Reintjes WAF 374 7.476:1 reduction gearbox and a 2000mm-diameter propeller.

A Cummins QSL9 auxiliary engine of 212kW @ 1800rpm will drive the trawler’s main hydraulic system. A Cummins 6BT5 electrical generator auxiliary engine will also be fitted.

Fuel and freshwater capacities will be 24,800 litres and 15,300 litres respectively.

On completion of the hull, the new-build will be launched at Szczecin before being towed to Macduff for machinery installation fitting-out.

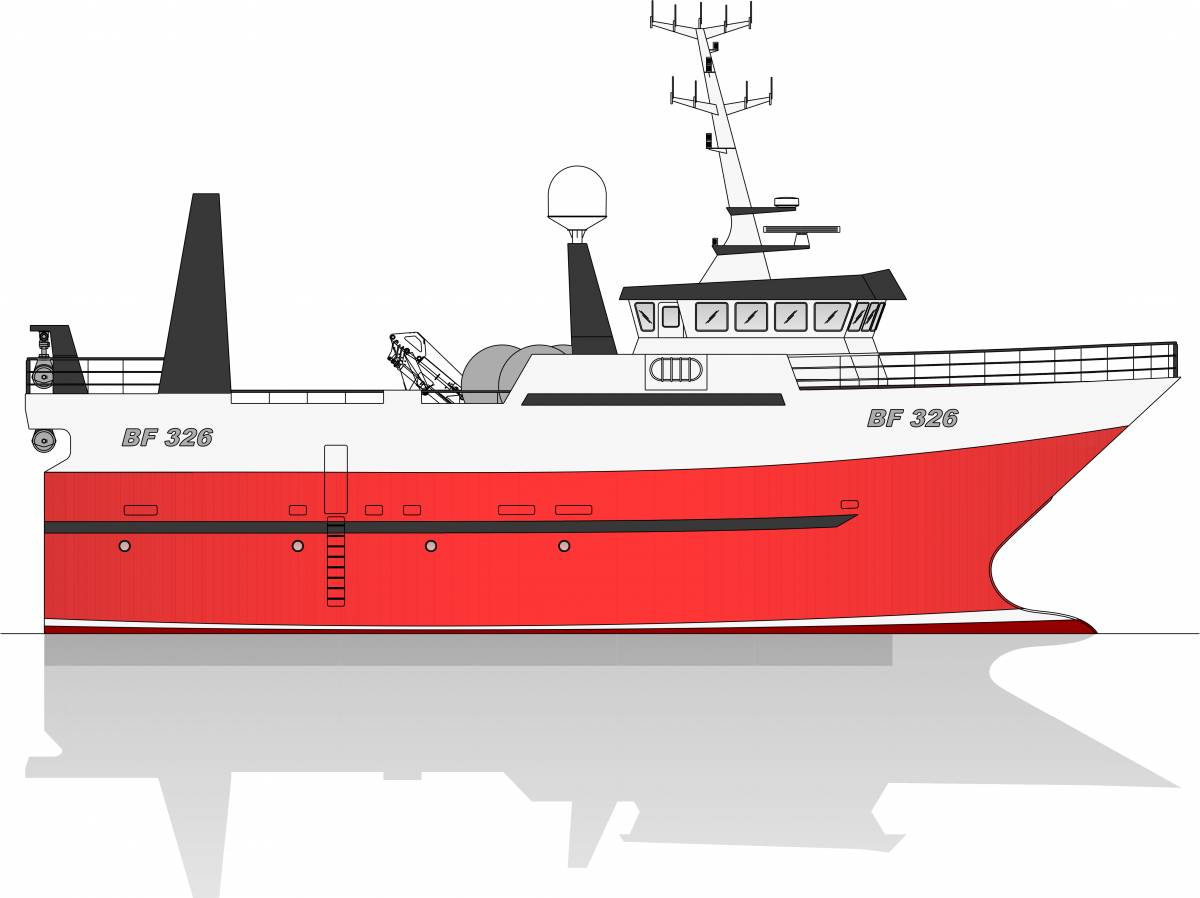

Also in Szczecin, the round bilge hull of a 29.9m stern trawler, for Whitehills skipper Mark Lovie and partners, is at an early stage of fabrication at the Finomar Shipyard.

Fabrication of this 24m twin-rig trawler for Nicol Fishing LLP will commence soon in Macduff Shipyards newbuild hall.

Profile of the 29m stern trawler Macduff Shipyards is building for Whitehills skipper Mark Lovie.

Macduff Shipyards will complete this 21.5m twin-rig trawler, for Peterhead skipper Andrew West and partners, later this year.

With a registered length of 23.95m and a beam of 10.5m, the stern trawler will feature three full-length decks; main – where most of the crew accommodation and the catch-handling system are located; shelter – gear-handling activity, main deck machinery and balance of internal accommodation; boat/forecastle deck – protection for trawl deck and ancillary deck machinery.

A MaK 8M20C main engine will drive a 3100mm-diameter CP propeller through a Mekanord 580HS 6.06:1 reduction gearbox.

Two Caterpillar C9 auxiliary engines, driving 415/3/15 generators, will also be fitted.

Fuel and freshwater capacities will be 93,000 litres and 26,300 litres respectively.

Rapp Marine of Peterhead will supply the vessel’s extensive package of deck machinery, including three split trawl winches (28.6t and 31.1t middle), 3 x split sweep winches (19.4t), 3 x bagging winches (12.5t), 2 x codend winches (10.3t) and 2 x Gilson winches (13.5t).

Macduff Shipyards is currently preparing to start fabrication of the first hull modules for a 23.95m twin-rig trawler for Gardenstown skipper Zander Nicol and partners. Featuring a similar hull form and engineroom package as Rebecca, the new build for Nicol Fishing will begin to take shape in Macduff Shipyards’ fabrication hall as soon as the Fraserburgh trawler is rolled out onto the adjacent slipway for launching.

28.7m whitefish vessel-building in Spain for Peterhead Company

A dual-purpose, twin-rig trawler and flyshooter is currently being built at the Nodosa Shipyard near Pontevedra in Spain, for Osprey Trawlers of Peterhead.

The 28.7m overall length vessel (23.99m registered) will have 10m of beam. Propulsion power will come from an ABC 6DZC main engine, driving a ducted five-bladed propeller through a Reintjes gearbox to give a speed of 10.5 knots and 19.5t bollard pull. Two MAN 320kW auxiliary engines driving 415/3/50 electrical generators will be fitted, together with a Caterpillar 86kW harbour genset.

To be supplied by Ibercisa, the hydraulic deck machinery package will include two x 2-speed flyshooting power reels, two x 2-speed net drums and a 20t trawl winch.

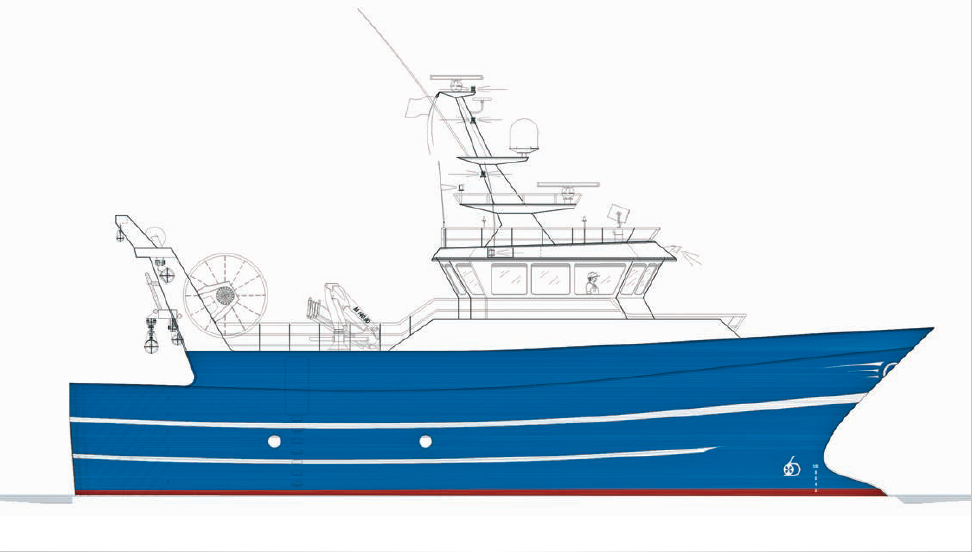

Profile of the 28.7m twin-rigger Nodosa Shipyard will deliver to Osprey Trawlers of Peterhead towards the end of the year.

The vessel’s fishroom is around 120m. and will be fitted with two Geneglace flake ice machines with a 2500kg daily capacity.

Scheduled for completion later this year, the new build will be skippered by Louwe de Boer, who is currently in the wheelhouse of Osprey Trawlers’ twin-rig trawler and flyshooter Good Hope H 357.

The second part of this feature will be coming soon…

The number of new over 15m boats currently on order is at the highest level since the millennium. In the next two years, nearly 20 new bespoke builds are scheduled to join the UK fleet. This number of new boats is expected to rise by around 25% when a number of further orders, now at an advanced stage of discussion, are expected to be confirmed in coming months. David Linkie reports

Above: The 27.7m, pair-seiner Rosebloom is one of nearly 20 new-builds at varying stages of construction or order for owners in Scotland.

The level of current investment in any industry has always been recognised as a strong indicator of its long-term future. Therefore, the fact that some £200m is currently being invested to build state-of-the-art new vessels, that will enable skippers and their crews to catch their annual quotas with enhanced safety, efficiency and financial viability, is a very positive and welcome sign.

Although the benefits associated with purpose-built vessels are well-known, the number of new additions in recent years has usually been counted on the fingers of one hand, as the already high average age of the UK fleet – 33 years – continues to rise.

So what significant factors, if any, have changed in the past 18 months when the first orders for the boats now under construction were placed?

In many respects, the answer is probably ‘not very many’, apart from a favourable Sterling/DK Kroner exchange rate reaching its zenith a few months ago.

One of the five new pelagic vessels scheduled for delivery to Scottish partnerships in the next 18 months.

For some years now, the level of demersal and pelagic stocks has been steadily increasing as the raft of technical and spatial measures, which fishermen endured considerable short-term pain to implement, quickly proved highly effective, and brought impressive results in a rapid timescale.

During this time, on a daily basis, whitefish and pelagic skippers have consistently reported a steadily increasing abundance of fish on the grounds. There is little doubt that had these encouraging signs been seen up until 20 years ago – when stock levels were the main criteria to be taken into consideration when placing new boat orders – they would have triggered a sustained flow of orders for new builds.

However, the march of time inevitably changed the situation, as a result of which, caution became a necessary criterium. Primarily, this was because of the uncertainty and lack of predictability that prevailed in top-down fisheries management, threatening to strangle what previously had been widely viewed as the lifeblood of the fishing industry going forward – investment in purpose-built new vessels.

A number of highly determined, strongly motivated younger skippers, who were already committed to the long-term future of the industry. These were represented on one side of the coin, the other face of which depicted unknown issues; fishing opportunities, access to quota and the implications of the looming landing obligation, all of which presented unknowns in terms of future business stability in years to come, and economic viability.

This contrasting situation represented a peculiar dilemma.

One of the reasons why the positive side of the coin, directly associated with the increase in stock levels – now beginning to be recognised by scientists – is prevailing today, can probably be traced back to the high oil prices of a few years ago, when the impact of fuel costs on a boat’s bottom-line expenses became a major concern for skippers and their crews.

Acutely aware of the impact this was having on their economic viability, hull form, propulsion efficiency and fuel economy became of increasing interest to skippers, naval architects and boatyards alike.

While new boats have always been associated with reduced expenses, incurring minimal maintenance costs in their initial years of service, the levels of fishing efficiency and savings generated by vessels incorporating new hull and centreline propulsion technology have moved up by several levels.

In doing so, this has added a significant factor to the positive side of the coin.

The successful economic performance delivered by the small number of new builds in recent years, including Benarkle II, Guardian Angell and Boy John, subsequently provided further positives.

These benefits gave further confirmation to what skippers already knew; that purpose-built new boats offered better long-term prospects than a boat that was perhaps already 20-30 years old. By this age, they require high levels of maintenance if they are to be kept for another 10-15 years, during which time skippers are continually on the back foot compared to colleagues who opt to go down the route of new-builds.

Benarkle II…

Guardian Angell…

… and Boy John are among the recent purpose-built new boats delivering optimum levels of fishing efficiency and fuel economy.

The new boats now on order are all designed to enable their owners to catch their existing allocation of annual quotas with optimum levels of catch quality, fishing efficiency, operational economy and crew safety, for years to come.

That the 17 new builds summarised in this overview feature are being built to replace vessels with a combined age of 317, serves as a timely reminder of the importance of the new tonnage.

By representing a strong statement of confidence in the future of the fishing industry, and one that is clearly fully endorsed by bank managers, the investment in new boats also provides a strong message of encouragement for young fishermen just starting out on their careers.

That experienced, but still young, skippers see a sustainable future in fishing, that will provide secure career prospects for new entrants, delivers an extremely important message.

On a similar theme, the boats due for replacement during the next 24-36 months will provide other skippers with the opportunity to replace their current boats. In recent years, the level of boat sales in the UK fleet has probably been at an all-time low, largely due to the shortage of orders for new-builds. Already, the imminent arrival of new vessels has begun to stimulate activity in second-hand boat sales. Given that these are also well recognised as being a barometer of a viable industry, this represents further positive news.

The new-builds also send the highly positive message to consumers of fish, throughout Britain and further afield, that the catching sector views current stock levels as being sustainable, and justifies investments of over £200m.

It should also be recognised that the new boats now on order will provide valuable employment, not only at boatyards, but also for the wide range of service companies that will be involved in the manufacture and supply of new machinery and equipment to each vessel.

It is particularly pleasing that the boats now on order include a general mix of fly-shooters, scallopers/single/twin-rig trawlers and pelagic vessels, ownership of which is also spread across a similarly broad geographical base.

Three Rs lead the way

Vestværftet will complete Rosebloom in the next two months, when the pair-seiner will start fishing with her sistership Boy John.

Although different types of vessel, the first three new-builds scheduled for completion in the next few months share one common characteristic, in that their names each begin with the letter R – Rosebloom, Rebecca and Resilient.

Fit-out of the new 27.7m, versatile, whitefish vessel Rosebloom INS 353 at Hvide Sande, Denmark, is now at an advanced stage of completion.

Designed for pair-seining and fly-shooting, the new vessel is being built for Avoch brothers Andrew, Donald, Johnny and Sandy McLeman, together with Denholm Fishselling Ltd. Rosebloom is a sistership to Boy John INS 110, which Vestværftet ApS handed over to its owners 14 months ago, since when the vessel has performed well, pair-seining with the previous Rosebloom.

The new Rosebloom has a registered length of 23.95m, 8.2m beam and a shelterdeck depth of 6.45m.

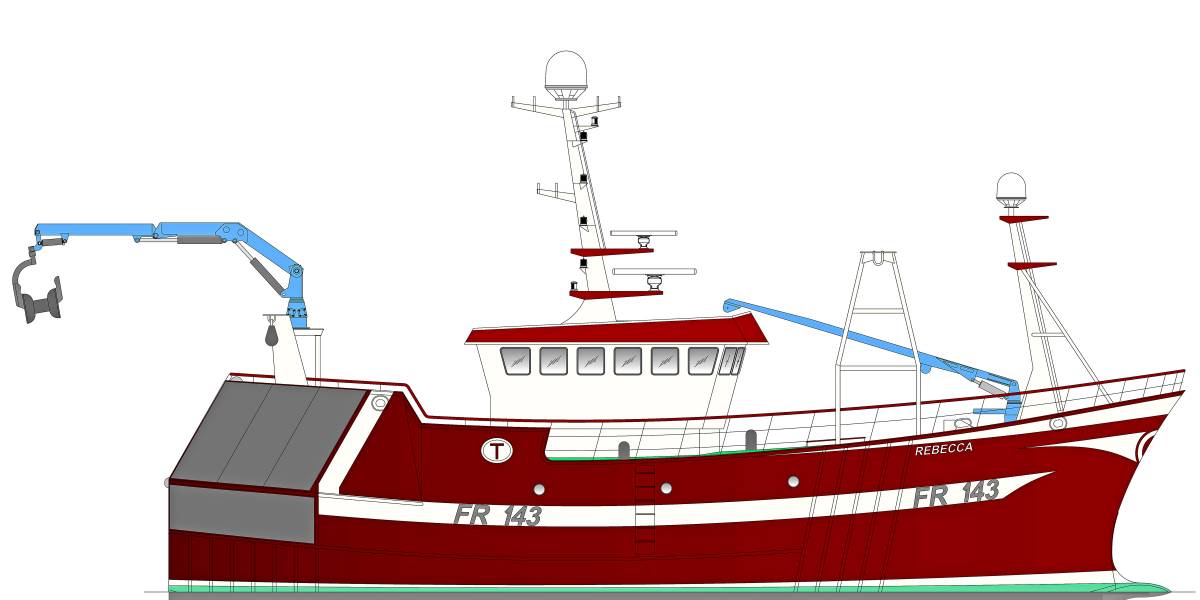

Profile of the new 24m Rebecca that Macduff Shipyards is building for a Fraserburgh family-partnership.

Fishing activities will be focused on two large-capacity 16t power reels, two split drums (2 x 10t) and 2 x 7.5t bagging winches manufactured by Kynde and Toft of Thyborøn. Catches will be bagged centrally over the transom using a 7t codend winch.

Like Boy John, Rosebloom will be powered by a Caterpillar 3508C main engine, Heimdal 9.4:1 reduction gearbox, and a matching Heimdal 2800mm-diameter CP propeller and nozzle.

Two Mitsubishi 6D16 auxiliary engines, driving 116kVA gensets, will also be housed in Rosebloom’s aft engineroom.

A new design of 23.95m twin-rig trawler for the Fraserburgh family-partnership of skippers Adam Tait and his sons Adam Jnr and Jonny Tait, is nearing an advanced stage of completion in Macduff Shipyards’ main fabrication hall.

With 7.40m of beam and a moulded depth of 4.20m, the underwater form of the double chine hull has been designed to provide a maximum smooth flow of water to a large propeller aperture, in order to deliver optimum levels of propulsion efficiency and fuel economy across all modes of operation.

Fit-out work in progress on Rebecca in Macduff Shipyards’ main fabrication hall.

The centreline machinery for the new Rebecca includes a Caterpillar C32 main engine, Masson 9:1 reduction gearbox and a 2500mm-diameter propeller.

Three Cummins auxiliary engines, one hydraulic and two electrical, are also installed in the engineroom.

The main items of deck machinery have been manufactured by the boatyard, with the customary three-drum trawl winch, housed in a dedicated winch compartment forward of the main catch-handling area amidships.

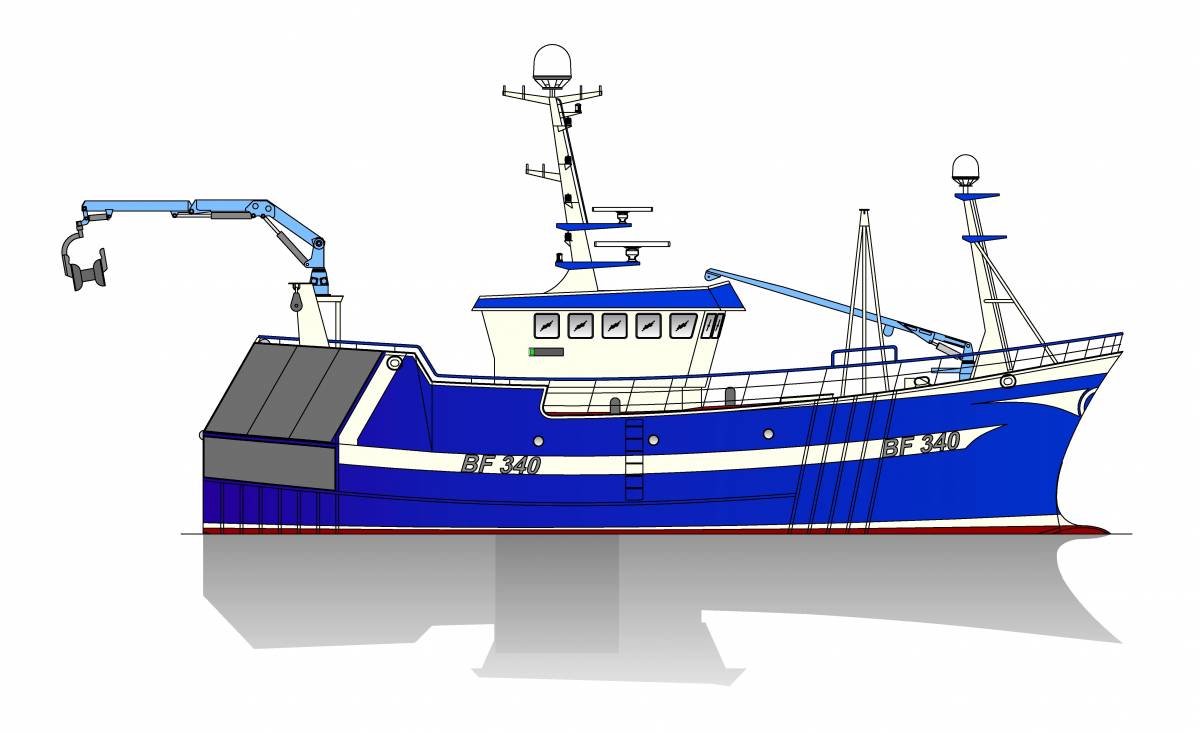

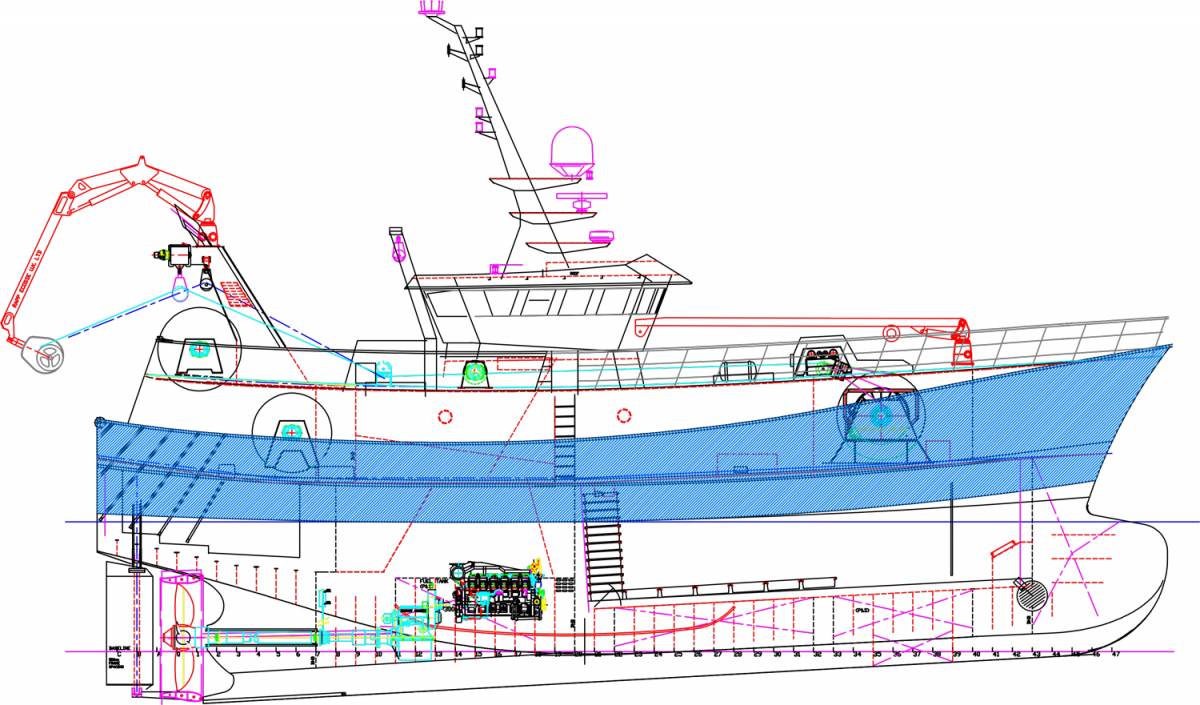

At Whitby, Parkol Marine Engineering is now fitting-out a new class of 27m dual-purpose seiner/trawler, for the Resilient Fishing Company Ltd of Shetland.

Designed by Ian Paton of SC McAllister & Co Ltd, for Whalsay skipper Arthur Polson, together with partners Edward Jamieson, John Montgomery and John Irvine, the whitefish vessel is of round bilge hull form, with a registered length of 23.95m and 7.8m of beam.

Profile drawing of the 27m seiner/trawler being built at Whitby for the Resilient Fishing Company Ltd.

The Mitsubishi S12R-MPTAW main engine will drive a 2700mm-diameter Finnoy VP propeller, through a Finnoy G50 FKV 10.75:1 reduction gearbox.

Two Mitsubishi 6D16T auxiliary engines will also be fitted.

Thyborøn Skibs and Motor A/S (Three Js) of Thyborøn, has designed and manufactured an extensive package of customised deck machinery.

Two power reels, with a core pull rating of 20t and a capacity of 3900m of 40mm-diameter seine rope, are positioned forward on the main deck. When fly-shooting, the power reels will operate through a Scantrol iSYM system, and a Scantrol auto-trawl system when single-rig trawling. The ropes/wires will be spooled onto the power reels by electronically-controlled guiding-on gear, incorporated into framework that will be fitted across the full width of the shelterdeck, aft of the power reels and forward of the vessel’s wheelhouse.

In order to deliver optimum leads when hauling back the seine-net ropes, or towing a single boat trawl, the hanging blocks will be positioned hydraulically by a full-width modular unit, mounted on the main fishing gantry, aft. Two 2 x 8t split net drums will be positioned on the shelterdeck, together with a 14.5t unit for installation on the quarter.

Busy times for Macduff Shipyards

At the same time as Macduff Shipyards is constructing a 25.70m dredger for Aberdeenshire Council in its building hall at Buckie, and fitting-out the 24m Rebecca in its main fabrication hall at Macduff, the hulls of two other trawlers are currently being built under sub-contract at shipyards in Szczecin, Poland.

The Kedat Shipyard has almost completed fabrication of a new twin-rig trawler, ordered by skipper Andrew West and partners of Peterhead, for which the main dimensions are LOA 21.50m, beam 7.10m and a depth moulded 4.10m.

The centreline machinery for the new build will include a Caterpillar Reintjes WAF 374 7.476:1 reduction gearbox and a 2000mm-diameter propeller.

A Cummins QSL9 auxiliary engine of 212kW @ 1800rpm will drive the trawler’s main hydraulic system. A Cummins 6BT5 electrical generator auxiliary engine will also be fitted.

Fuel and freshwater capacities will be 24,800 litres and 15,300 litres respectively.

On completion of the hull, the new-build will be launched at Szczecin before being towed to Macduff for machinery installation fitting-out.

Also in Szczecin, the round bilge hull of a 29.9m stern trawler, for Whitehills skipper Mark Lovie and partners, is at an early stage of fabrication at the Finomar Shipyard.

Fabrication of this 24m twin-rig trawler for Nicol Fishing LLP will commence soon in Macduff Shipyards newbuild hall.

Profile of the 29m stern trawler Macduff Shipyards is building for Whitehills skipper Mark Lovie.

Macduff Shipyards will complete this 21.5m twin-rig trawler, for Peterhead skipper Andrew West and partners, later this year.

With a registered length of 23.95m and a beam of 10.5m, the stern trawler will feature three full-length decks; main – where most of the crew accommodation and the catch-handling system are located; shelter – gear-handling activity, main deck machinery and balance of internal accommodation; boat/forecastle deck – protection for trawl deck and ancillary deck machinery.

A MaK 8M20C main engine will drive a 3100mm-diameter CP propeller through a Mekanord 580HS 6.06:1 reduction gearbox.

Two Caterpillar C9 auxiliary engines, driving 415/3/15 generators, will also be fitted.

Fuel and freshwater capacities will be 93,000 litres and 26,300 litres respectively.

Rapp Marine of Peterhead will supply the vessel’s extensive package of deck machinery, including three split trawl winches (28.6t and 31.1t middle), 3 x split sweep winches (19.4t), 3 x bagging winches (12.5t), 2 x codend winches (10.3t) and 2 x Gilson winches (13.5t).

Macduff Shipyards is currently preparing to start fabrication of the first hull modules for a 23.95m twin-rig trawler for Gardenstown skipper Zander Nicol and partners. Featuring a similar hull form and engineroom package as Rebecca, the new build for Nicol Fishing will begin to take shape in Macduff Shipyards’ fabrication hall as soon as the Fraserburgh trawler is rolled out onto the adjacent slipway for launching.

28.7m whitefish vessel-building in Spain for Peterhead Company

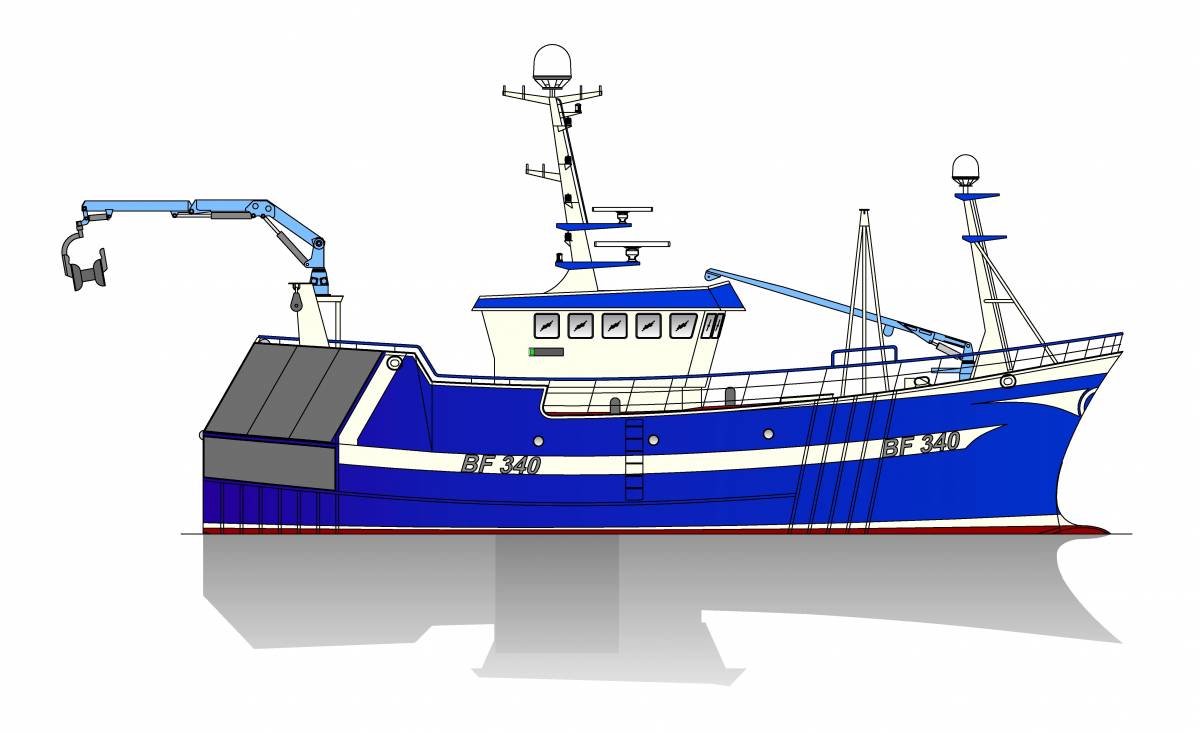

A dual-purpose, twin-rig trawler and flyshooter is currently being built at the Nodosa Shipyard near Pontevedra in Spain, for Osprey Trawlers of Peterhead.

The 28.7m overall length vessel (23.99m registered) will have 10m of beam. Propulsion power will come from an ABC 6DZC main engine, driving a ducted five-bladed propeller through a Reintjes gearbox to give a speed of 10.5 knots and 19.5t bollard pull. Two MAN 320kW auxiliary engines driving 415/3/50 electrical generators will be fitted, together with a Caterpillar 86kW harbour genset.

To be supplied by Ibercisa, the hydraulic deck machinery package will include two x 2-speed flyshooting power reels, two x 2-speed net drums and a 20t trawl winch.

Profile of the 28.7m twin-rigger Nodosa Shipyard will deliver to Osprey Trawlers of Peterhead towards the end of the year.

The vessel’s fishroom is around 120m. and will be fitted with two Geneglace flake ice machines with a 2500kg daily capacity.

Scheduled for completion later this year, the new build will be skippered by Louwe de Boer, who is currently in the wheelhouse of Osprey Trawlers’ twin-rig trawler and flyshooter Good Hope H 357.

The second part of this feature will be coming soon…