Less than three months ago, Lossiemouth skipper Scott Milne and the crew of the Peterhead-based seine-netter Tranquility PD 35 were dealt a major blow when their boat was extensively damaged by a potentially life-threatening fire, following an arsonist attack, reports David Linkie

Above: Tranquility leaves a snowy Hvide Sande astern, before fishing her way across the North Sea to Peterhead.

While Peterhead firemen were able to prevent the fire from reaching the engineroom and the fish-handling area forward of the deck casing, the vessel’s accommodation areas and wheelhouse were completely burnt out.

Facing the prospect of a long period of time ashore until the seiner could be refurbished, skipper Scott Milne and the vessel’s owners, Lunar Fishing Ltd of Peterhead, immediately began to look at other possible solutions.

Tranquility’s crew: left to right – Gary Milne, John Buchan (fishroom man), Paul Henderson, James Stewart (engineer), skipper Scott Milne, Marshall Stewart (cook) and Martin Cardno.

Stern view of Tranquility showing working arrangements across the transom.

General view from forward of Tranquility’s automated fish-handling system.

The slim main console in the modern wheelhouse.

This proactive approach was designed to keep Tranquility’s highly experienced crew together, in addition to being able to maintain their well-established pattern of landing top quality catches, including MSC-accredited haddock, from 3-4 day trips, for which local processors have established important long-term demand and orders, in a highly competitive marketplace.

Exploring alternative options led skipper Scott Milne to Denmark, where the 25.56m fly-shooter Anders Nees L-426, owned by a well-known Thyborøn family-based partnership, led by the highly respected skipper Tonny Nees, was potentially available.

In the first week of January, all parties shook hands on the transaction. At this point, Anders Nees was immediately slipped, in preparation for the hull being hydro-blasted and fully repainted in Lunar Fishing’s distinctive shade of blue.

Appropriately, the external refurbishment work, which included cutting and welding new name and home port profiles to the hull, was carried out by Vestværftet ApS at Hvide Sande, where Anders Nees was built in 2012 for skipper Tonny Nees, his father Svend Erik Nees, and engineer Arne Christensen.

The new vessel was a slightly bigger replacement for the previous 23m Anders Nees, delivered by Vestværftet ApS in 2010 and sold to a Norwegian company.

Having already spent considerable time with skipper Scott Milne and his crew at Hvide Sande, Tonny Nees, and Arne Christensen were aboard Tranquility when the seiner fished her way home from Denmark before landing into Peterhead for the first time.

Conducted in some fairly scruffy weather, during which Tranquility handled well, the presence of the boat’s original skipper and engineer was much appreciated by her new skipper and crew.

Although the new Tranquility represents a new style of fly-shooter for the Scottish fleet, her distinctive profile will become increasingly familiar over the next two years, when a number of similar, although slightly longer, new-builds by Vestværftet ApS are scheduled to complete delivery trips across the North Sea from Denmark.

The new Boy Andrew, a 27m seine-net vessel for the Bremner Fishing Company Ltd, will be welcomed home to Caithness in December of this year, while Vestværftet will complete similarly-sized whitefish vessels for Fraserburgh skipper Davie Milne and the Tranquility Fishing Company Ltd of Whalsay, Shetland, in May 2017 and March 2018 respectively.

Currently fitting-out Rosebloom INS 353 for completion in the early spring, when the 28m pair-seiner will team up with her 14-month-old sistership Boy John INS 110, Vestværftet ApS will also deliver a similarly-sized single-rig trawler to Orkney Tommy Tulloch next year.

Insured by Sunderland Marine and landing through Don Fishing Company Ltd, the new Tranquility has principle dimensions of: LOA 25.50m, registered length 23.95m beam 7.70m, shelterdeck moulded depth of 6.20m and a GT of 242t.

Further evidence of Tranquility’s deep hull form is shown by the forward and aft drafts of 3.6m and 4.4m respectively.

All fly-shooting activities are carried out from the full-length shelterdeck, where the codend is taken aboard aft on the starboard side. Whitefish catches are selected and gutted amidship on the main deck.

The hull below the main deck is subdivided into five watertight compartments; forepeak, tank section with deep fuel tanks port and starboard/thruster compartment, insulated fishroom, engineroom, and aft peak, housing fuel, lube and hydraulic oil tanks.

The main accommodation areas are arranged across the forward section of the main deck. The messdeck is located on the starboard side of a central passageway leading forward from the main deck, with the galley to port, forward of a large shower/toilet compartment. Four twin-berth cabins are positioned across the beam forward of the day galley and messdeck areas.

The large power reels are recessed into the shelterdeck abaft the wheelhouse.

Hydraulically-positioned hanging blocks can be moved across the stern gantry when fly-shooting, to suit prevailing wind and tidal conditions.

Tranquility’s modern galley.

Tranquility’s fishing console.

The four-year-old Danish built Tranquility is scheduled to be joined by a number of similar whitefish vessels from Vestværftet ApS in the next two years.

The modern layout of the wheelhouse, together with the quality of finish, reflects the level of thought and workmanship that the owners and boatyard personnel put into Anders Nees when the vessel was built, as well as the standards to which the vessel has been looked after since her completion.

An array of Furuno navigation and fishfinding equipment, Olex and Sodena plotting systems and Sailor SSB and VHF radios are flush-mounted in the U-shaped, slim-profile main console, which also incorporates a desk area for use when skipper Scott Milne is sending eLogs and general emails ashore.

A large horseshoe seating area is arranged in the aft port corner of the wheelhouse, together with a compact sink and fridge unit.

The fishing console, from which the skipper has full control of all gear handling operations, is positioned across the centreline.

An extensive catch-handling system extends from port of the centreline to the starboard side of Tranquility, between the forward accommodation casing and a large reception hopper at the starboard quarter. Capable of holding around 250 boxes of whitefish, the fish hopper is flanked to port by a general-purpose store and the main engineroom walk-in companionway access on the portside of the main deck.

Thyborøn Skibs and Motor A/S (Three J’s) manufactured Tranquility’s deck machinery. Twin direct-drive power reels, with a diameter of 2.1m and a length of 1.8m, each capable of holding 3300m of 44mm seine rope, are recessed down into the shelterdeck aft of the wheelhouse. Two-speed Poclain hydraulic motors give the power reels hauling speeds of 28rpm and 54rpm and a core pull of 14.5t.

Skipper Scott Milne controls all aspects of shooting and hauling the ropes from the wheelhouse, using a Thyborøn seine-net computer system mounted in a fishing console overlooking the transom. The system provides a constant display of hauling speed, hydraulic pressure, tension, rope length and the differential between port and starboard warps. When the selected differential is exceeded, the reel for the longer rope is automatically slowed down before reverting to the chosen rate. When shooting away the ropes, the main motor is disengaged, allowing the winch reels to freewheel, with a smaller hydraulic motor being fitted for braking purposes.

Tranquility is continuing to work the same combination of Selstad 44mm-diameter leaded seine rope and similar sized wire in the bights towards the net that were previously used by Anders Nees, which in turn mirrored those worked by skipper Scott Milne.

When running the ropes and subsequently heaving back, they are shot through moveable hanging blocks mounted on the underside of the aft-raked stern gantry. These blocks are positioned remotely from the wheelhouse by a hydraulic motor mounted on the portside of the gantry, that drives a large sprocket wheel and a heavy-duty chain.

As the port set of warps are shot, the Dan Leno and the sweeps are attached to the wire using a snatch block mounted on the transom gunwale, in conjunction with a quick-release clip.

Two sets of split net drums (2 x 14t) are positioned towards the transom, directly under the stern gantry. A third single net drum (6t) is positioned further forward on the vessel’s centreline. A clean ground grassrope seine net is expected to be worked from this lighter drum during the summer months, but while Tranquility’s skipper and crew run up to speed with the different working arrangements of their new boat, it is currently being used as a fleeting drum, should the need arise.

Starboard quarter view of Tranquility.

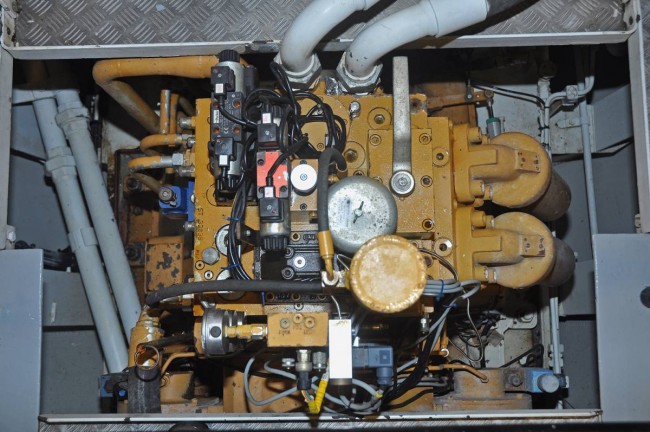

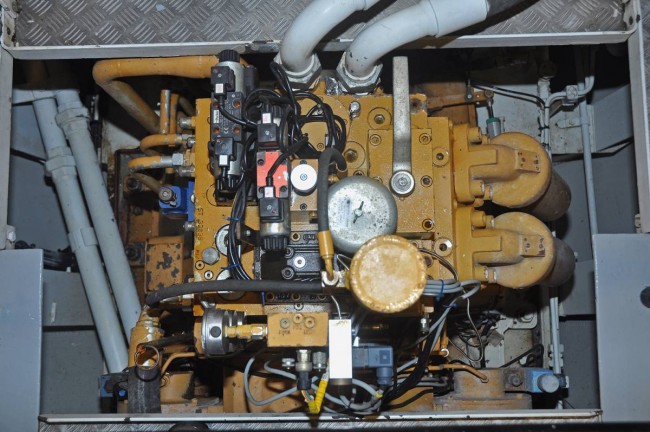

The Mekanord 450HS 6.06:1 reduction gearbox.

Three net drums are positioned on the shelterdeck abaft the power reels.

The power reels are 2.1m long and hold 3300m of 44mm-diameter Selstad leaded seine rope and wire.

Tranquility is currently using two high standing seine-nets, one rigged on 12-inch discs and the second on 14-inch discs, supplied to skipper Tonny Nees by Thyborøn Trawl Nets.

Whitefish catches are lifted aboard using a 6t Gilson winch, mounted on the starboard side of the stern gantry directly above the codend hatch.

Tranquility is powered by a Caterpillar 3508C Tier II-compliant main engine that develops 578kW @ 1200rpm and is coupled to a Mekanord 450HS 6.06:1 reduction gearbox, to turn a Korsør CP21 2200mm-diameter, 4-bladed CP propeller mounted in a matching high-efficiency nozzle.

The main hydraulic system is driven by two gearbox-mounted PTOs.

Electrical power is provided by two Volvo Penta D5A T auxiliary engines (77kW @1500rpm), powering 78kVA Stamford 415/3/50 generators.

Steering gear is from Scan-Steering and is an MT-1600 system with two electric-hydraulic pumps and the boat also has a 160hp Hundested SFT4 side thruster.

Housed in a combination of four main deep tanks (two forward and two aft), together with a daily service and double bottom tank under the fishroom floor, Tranquility can start a trip carrying 31,000 litres of fuel. 22,000 litres of freshwater, equally divided between domestic and ice-making purposes, are also carried.

Malicious fire

Started on the seine net, wound on the drum on the main deck, the accelerant-fuelled fire quickly engulfed Tranquility’s cruiser stern, when the excessive heat caused a galley window looking onto the quarter to implode.

This immediately gave the flames direct access to the accommodation area on the main deck, where, fanned by strong winds, unfortunately blowing directly onto the stern of Tranquility, the fire rapidly spread into the wheelhouse (Fishing News, 3 December 2015).

At the height of the fire, the temperature of the steel plating above the waterline of Tranquility’s cruiser stern reach 425°C, before the cooling effect of water hosed into the steering gear compartment began to prove effective in lowering the temperature associated with the fire in the accommodation cabin.

Peterhead firefighters tackle the fire on Tranquility at 23.00hrs on Thursday 19 November.

Immediately after the fire, police arrested and charged a 35-year-old foreign national, who after a brief appearance in the local Magistrates’ Court, was charged with wilful fire-raising, before being retained in custody.

Skipper Scott Milne and his crew regularly slept onboard Tranquility after landing into Peterhead fishmarket in the middle of the night, before driving nearly 100 miles home to Lossiemouth for the weekend. Understandably, they were very shocked that the fire could have been deliberately started by someone who could not be certain that there were no crew sleeping aboard.

Having seen the challenging and difficult situation that firemen from the Peterhead station found themselves faced with when tackling the inferno on Tranquility, the crew were understandably keen for their sincere thanks to be expressed in this feature.

The crew were also unanimous that the proceeds from the traditional first box, £250, should go to Peterhead Fire Station, in recognition of the valiant efforts firemen made on that difficult night less than three months ago.

Quality-orientated automated fish-handling system

Tranquility features a highly-automated whitefish handling system, designed and fabricated by the well-known Danish company KM Services, that will ensure optimum levels of catch quality in years to come while minimising the amount of manual effort required by the crew.

As a similar system, incorporating segmented revolving drums into which selections of whitefish were made, was installed when the previous Tranquility was built, the crew are already very familiar with this feature of their new boat.

A short elevated conveyor picks fish up almost from deck level at the forward corner of the starboard reception hopper, moving diagonally forward beyond the centreline of the vessel before they are transferred onto a long waist-height conveyor arranged across the middle two-thirds of Tranquility’s beam amidships. From here, the crew select and gut the catch while standing on raised gratings with their backs against a stanchion rail.

An elevated conveyor takes whitefish from the catch hopper, diagonally across the main deck to the selecting/gutting conveyor.

Chutes direct sections of whitefish from the circular washer…

… directly to aligned hoppers on the aft side of the fishroom for weighing and labelling.

After gutting, fish are placed into a long revolving stainless steel drum rotating on a horizontal axis in a watertight trough arranged parallel to, and forward of, the main fish conveyor. With a length of more than 2m and a diameter of 1000mm, the drum is divided into 18 sections, six transversely and three radially. After an adjustable period of time (longer for larger fish), during which fish in the receiving section are sprayed with water, the drum is automatically rotated through 120°. As a result, the fish are then fully immersed in water at the bottom of the trough and washed thoroughly, for a pre-selected length of time, after which the drum rotates through a further 120°. This second movement lifts fish clear of the washer, and they slide across drainage shelves before being automatically transferred by one of six stainless steel chutes down to the fishroom, via dedicated coamings in the main deck.

The fish-handling area is kept clear of water by Hidrostal pumps fitted in deck sumps.

In order to keep the initial automated selections made into the revolving bins, six vertical hoppers are placed against the aft bulkhead of the fishroom, from which fish are weighed using a set of Marelec electronic scales, before a label displaying all relevant information, including species, grade size, time, and date, is printed off and put on the corresponding box. This information is also transferred automatically to a PC in the wheelhouse, where it is accumulated to provide a running total of Tranquility’s trip.

Served by a dedicated flush deck-hatch and a separate easy-access companionway located aft on the starboard side, the fishroom on Tranquility, which extends over more than half the boat’s registered length, can accommodate some 1,200 stacker boxes, supplied by Box Pool Solutions Ltd, stacked up to 12-high.

In addition, 9t of flake ice made by a 4.5t Buus ice machine can be stored in full-height lockers on the port side, directly under a dedicated refrigeration plant room on the main deck.

Nordkøl ApS of Hanstholm supplied the ice machine, in addition to fitting the 22mm-diameter stainless steel refrigeration pipes mounted on the deckhead.

When landing, an electrical winch is used to pull stacks of boxes aft towards the portside, from where they are lifted ashore through a large hatch by a Thistlelift 8t/m stiff boom landing crane served by a 1.5t winch.

Tranquility was first automated seine-netter

Built by Miller (Methil) Ltd in 2000, the previous Tranquility was the first fly-shooter in the Scottish fleet equipped with power reels for automated seine netting.

Now in the early stages of being refurbished for new owners by Macduff Shipyards, the previous Tranquility was the first automated fly-shooting seine-netter in the Scottish fleet.

23.95m LOA and with a beam of 7.5m, Tranquility INS 35 was built for Lossiemouth skipper Alistair Milne by Miller (Methil) Ltd in 2000, to plans drawn up by Macduff Ship Design Ltd.

Powered by a Caterpillar 3508 main engine of 592kW, Tranquility was the first vessel equipped with a pair of 15t power reels manufactured and commissioned by Smith Maritime of Peterhead.

Tranquility was the third vessel of the same name to be skippered by Alistair Milne, who bought his first boat, Minerva FR 147, from Jimmy Thomson of Fraserburgh in 1989. The 79ft wooden-hulled Minerva had been built by Richard Irvin in 1974 for Philip Morgan of Peterhead as Daisy PD 123. Alistair Milne’s second Tranquility was the 86ft steel-hulled seiner Dondarr INS 104, built at the John Lewis yard Aberdeen in 1975, as Harvest Hope II PD 148.

Lunar Fishing bought the third Tranquility a few years ago, since when Alistair Milne, and subsequently his son Scott, continued to fish the boat, usually working 3-4 day trips after sailing the back ’o Sunday; a well-established routine that the new Tranquility is now beginning to follow.

Work starts to remove the fire damage, after the seine-netter was towed to Macduff for total refurbishment.

Read more from Fishing News here.

Less than three months ago, Lossiemouth skipper Scott Milne and the crew of the Peterhead-based seine-netter Tranquility PD 35 were dealt a major blow when their boat was extensively damaged by a potentially life-threatening fire, following an arsonist attack, reports David Linkie

Above: Tranquility leaves a snowy Hvide Sande astern, before fishing her way across the North Sea to Peterhead.

While Peterhead firemen were able to prevent the fire from reaching the engineroom and the fish-handling area forward of the deck casing, the vessel’s accommodation areas and wheelhouse were completely burnt out.

Facing the prospect of a long period of time ashore until the seiner could be refurbished, skipper Scott Milne and the vessel’s owners, Lunar Fishing Ltd of Peterhead, immediately began to look at other possible solutions.

Tranquility’s crew: left to right – Gary Milne, John Buchan (fishroom man), Paul Henderson, James Stewart (engineer), skipper Scott Milne, Marshall Stewart (cook) and Martin Cardno.

Stern view of Tranquility showing working arrangements across the transom.

General view from forward of Tranquility’s automated fish-handling system.

The slim main console in the modern wheelhouse.

This proactive approach was designed to keep Tranquility’s highly experienced crew together, in addition to being able to maintain their well-established pattern of landing top quality catches, including MSC-accredited haddock, from 3-4 day trips, for which local processors have established important long-term demand and orders, in a highly competitive marketplace.

Exploring alternative options led skipper Scott Milne to Denmark, where the 25.56m fly-shooter Anders Nees L-426, owned by a well-known Thyborøn family-based partnership, led by the highly respected skipper Tonny Nees, was potentially available.

In the first week of January, all parties shook hands on the transaction. At this point, Anders Nees was immediately slipped, in preparation for the hull being hydro-blasted and fully repainted in Lunar Fishing’s distinctive shade of blue.

Appropriately, the external refurbishment work, which included cutting and welding new name and home port profiles to the hull, was carried out by Vestværftet ApS at Hvide Sande, where Anders Nees was built in 2012 for skipper Tonny Nees, his father Svend Erik Nees, and engineer Arne Christensen.

The new vessel was a slightly bigger replacement for the previous 23m Anders Nees, delivered by Vestværftet ApS in 2010 and sold to a Norwegian company.

Having already spent considerable time with skipper Scott Milne and his crew at Hvide Sande, Tonny Nees, and Arne Christensen were aboard Tranquility when the seiner fished her way home from Denmark before landing into Peterhead for the first time.

Conducted in some fairly scruffy weather, during which Tranquility handled well, the presence of the boat’s original skipper and engineer was much appreciated by her new skipper and crew.

Although the new Tranquility represents a new style of fly-shooter for the Scottish fleet, her distinctive profile will become increasingly familiar over the next two years, when a number of similar, although slightly longer, new-builds by Vestværftet ApS are scheduled to complete delivery trips across the North Sea from Denmark.

The new Boy Andrew, a 27m seine-net vessel for the Bremner Fishing Company Ltd, will be welcomed home to Caithness in December of this year, while Vestværftet will complete similarly-sized whitefish vessels for Fraserburgh skipper Davie Milne and the Tranquility Fishing Company Ltd of Whalsay, Shetland, in May 2017 and March 2018 respectively.

Currently fitting-out Rosebloom INS 353 for completion in the early spring, when the 28m pair-seiner will team up with her 14-month-old sistership Boy John INS 110, Vestværftet ApS will also deliver a similarly-sized single-rig trawler to Orkney Tommy Tulloch next year.

Insured by Sunderland Marine and landing through Don Fishing Company Ltd, the new Tranquility has principle dimensions of: LOA 25.50m, registered length 23.95m beam 7.70m, shelterdeck moulded depth of 6.20m and a GT of 242t.

Further evidence of Tranquility’s deep hull form is shown by the forward and aft drafts of 3.6m and 4.4m respectively.

All fly-shooting activities are carried out from the full-length shelterdeck, where the codend is taken aboard aft on the starboard side. Whitefish catches are selected and gutted amidship on the main deck.

The hull below the main deck is subdivided into five watertight compartments; forepeak, tank section with deep fuel tanks port and starboard/thruster compartment, insulated fishroom, engineroom, and aft peak, housing fuel, lube and hydraulic oil tanks.

The main accommodation areas are arranged across the forward section of the main deck. The messdeck is located on the starboard side of a central passageway leading forward from the main deck, with the galley to port, forward of a large shower/toilet compartment. Four twin-berth cabins are positioned across the beam forward of the day galley and messdeck areas.

The large power reels are recessed into the shelterdeck abaft the wheelhouse.

Hydraulically-positioned hanging blocks can be moved across the stern gantry when fly-shooting, to suit prevailing wind and tidal conditions.

Tranquility’s modern galley.

Tranquility’s fishing console.

The four-year-old Danish built Tranquility is scheduled to be joined by a number of similar whitefish vessels from Vestværftet ApS in the next two years.

The modern layout of the wheelhouse, together with the quality of finish, reflects the level of thought and workmanship that the owners and boatyard personnel put into Anders Nees when the vessel was built, as well as the standards to which the vessel has been looked after since her completion.

An array of Furuno navigation and fishfinding equipment, Olex and Sodena plotting systems and Sailor SSB and VHF radios are flush-mounted in the U-shaped, slim-profile main console, which also incorporates a desk area for use when skipper Scott Milne is sending eLogs and general emails ashore.

A large horseshoe seating area is arranged in the aft port corner of the wheelhouse, together with a compact sink and fridge unit.

The fishing console, from which the skipper has full control of all gear handling operations, is positioned across the centreline.

An extensive catch-handling system extends from port of the centreline to the starboard side of Tranquility, between the forward accommodation casing and a large reception hopper at the starboard quarter. Capable of holding around 250 boxes of whitefish, the fish hopper is flanked to port by a general-purpose store and the main engineroom walk-in companionway access on the portside of the main deck.

Thyborøn Skibs and Motor A/S (Three J’s) manufactured Tranquility’s deck machinery. Twin direct-drive power reels, with a diameter of 2.1m and a length of 1.8m, each capable of holding 3300m of 44mm seine rope, are recessed down into the shelterdeck aft of the wheelhouse. Two-speed Poclain hydraulic motors give the power reels hauling speeds of 28rpm and 54rpm and a core pull of 14.5t.

Skipper Scott Milne controls all aspects of shooting and hauling the ropes from the wheelhouse, using a Thyborøn seine-net computer system mounted in a fishing console overlooking the transom. The system provides a constant display of hauling speed, hydraulic pressure, tension, rope length and the differential between port and starboard warps. When the selected differential is exceeded, the reel for the longer rope is automatically slowed down before reverting to the chosen rate. When shooting away the ropes, the main motor is disengaged, allowing the winch reels to freewheel, with a smaller hydraulic motor being fitted for braking purposes.

Tranquility is continuing to work the same combination of Selstad 44mm-diameter leaded seine rope and similar sized wire in the bights towards the net that were previously used by Anders Nees, which in turn mirrored those worked by skipper Scott Milne.

When running the ropes and subsequently heaving back, they are shot through moveable hanging blocks mounted on the underside of the aft-raked stern gantry. These blocks are positioned remotely from the wheelhouse by a hydraulic motor mounted on the portside of the gantry, that drives a large sprocket wheel and a heavy-duty chain.

As the port set of warps are shot, the Dan Leno and the sweeps are attached to the wire using a snatch block mounted on the transom gunwale, in conjunction with a quick-release clip.

Two sets of split net drums (2 x 14t) are positioned towards the transom, directly under the stern gantry. A third single net drum (6t) is positioned further forward on the vessel’s centreline. A clean ground grassrope seine net is expected to be worked from this lighter drum during the summer months, but while Tranquility’s skipper and crew run up to speed with the different working arrangements of their new boat, it is currently being used as a fleeting drum, should the need arise.

Starboard quarter view of Tranquility.

The Mekanord 450HS 6.06:1 reduction gearbox.

Three net drums are positioned on the shelterdeck abaft the power reels.

The power reels are 2.1m long and hold 3300m of 44mm-diameter Selstad leaded seine rope and wire.

Tranquility is currently using two high standing seine-nets, one rigged on 12-inch discs and the second on 14-inch discs, supplied to skipper Tonny Nees by Thyborøn Trawl Nets.

Whitefish catches are lifted aboard using a 6t Gilson winch, mounted on the starboard side of the stern gantry directly above the codend hatch.

Tranquility is powered by a Caterpillar 3508C Tier II-compliant main engine that develops 578kW @ 1200rpm and is coupled to a Mekanord 450HS 6.06:1 reduction gearbox, to turn a Korsør CP21 2200mm-diameter, 4-bladed CP propeller mounted in a matching high-efficiency nozzle.

The main hydraulic system is driven by two gearbox-mounted PTOs.

Electrical power is provided by two Volvo Penta D5A T auxiliary engines (77kW @1500rpm), powering 78kVA Stamford 415/3/50 generators.

Steering gear is from Scan-Steering and is an MT-1600 system with two electric-hydraulic pumps and the boat also has a 160hp Hundested SFT4 side thruster.

Housed in a combination of four main deep tanks (two forward and two aft), together with a daily service and double bottom tank under the fishroom floor, Tranquility can start a trip carrying 31,000 litres of fuel. 22,000 litres of freshwater, equally divided between domestic and ice-making purposes, are also carried.

Malicious fire

Started on the seine net, wound on the drum on the main deck, the accelerant-fuelled fire quickly engulfed Tranquility’s cruiser stern, when the excessive heat caused a galley window looking onto the quarter to implode.

This immediately gave the flames direct access to the accommodation area on the main deck, where, fanned by strong winds, unfortunately blowing directly onto the stern of Tranquility, the fire rapidly spread into the wheelhouse (Fishing News, 3 December 2015).

At the height of the fire, the temperature of the steel plating above the waterline of Tranquility’s cruiser stern reach 425°C, before the cooling effect of water hosed into the steering gear compartment began to prove effective in lowering the temperature associated with the fire in the accommodation cabin.

Peterhead firefighters tackle the fire on Tranquility at 23.00hrs on Thursday 19 November.

Immediately after the fire, police arrested and charged a 35-year-old foreign national, who after a brief appearance in the local Magistrates’ Court, was charged with wilful fire-raising, before being retained in custody.

Skipper Scott Milne and his crew regularly slept onboard Tranquility after landing into Peterhead fishmarket in the middle of the night, before driving nearly 100 miles home to Lossiemouth for the weekend. Understandably, they were very shocked that the fire could have been deliberately started by someone who could not be certain that there were no crew sleeping aboard.

Having seen the challenging and difficult situation that firemen from the Peterhead station found themselves faced with when tackling the inferno on Tranquility, the crew were understandably keen for their sincere thanks to be expressed in this feature.

The crew were also unanimous that the proceeds from the traditional first box, £250, should go to Peterhead Fire Station, in recognition of the valiant efforts firemen made on that difficult night less than three months ago.

Quality-orientated automated fish-handling system

Tranquility features a highly-automated whitefish handling system, designed and fabricated by the well-known Danish company KM Services, that will ensure optimum levels of catch quality in years to come while minimising the amount of manual effort required by the crew.

As a similar system, incorporating segmented revolving drums into which selections of whitefish were made, was installed when the previous Tranquility was built, the crew are already very familiar with this feature of their new boat.

A short elevated conveyor picks fish up almost from deck level at the forward corner of the starboard reception hopper, moving diagonally forward beyond the centreline of the vessel before they are transferred onto a long waist-height conveyor arranged across the middle two-thirds of Tranquility’s beam amidships. From here, the crew select and gut the catch while standing on raised gratings with their backs against a stanchion rail.

An elevated conveyor takes whitefish from the catch hopper, diagonally across the main deck to the selecting/gutting conveyor.

Chutes direct sections of whitefish from the circular washer…

… directly to aligned hoppers on the aft side of the fishroom for weighing and labelling.

After gutting, fish are placed into a long revolving stainless steel drum rotating on a horizontal axis in a watertight trough arranged parallel to, and forward of, the main fish conveyor. With a length of more than 2m and a diameter of 1000mm, the drum is divided into 18 sections, six transversely and three radially. After an adjustable period of time (longer for larger fish), during which fish in the receiving section are sprayed with water, the drum is automatically rotated through 120°. As a result, the fish are then fully immersed in water at the bottom of the trough and washed thoroughly, for a pre-selected length of time, after which the drum rotates through a further 120°. This second movement lifts fish clear of the washer, and they slide across drainage shelves before being automatically transferred by one of six stainless steel chutes down to the fishroom, via dedicated coamings in the main deck.

The fish-handling area is kept clear of water by Hidrostal pumps fitted in deck sumps.

In order to keep the initial automated selections made into the revolving bins, six vertical hoppers are placed against the aft bulkhead of the fishroom, from which fish are weighed using a set of Marelec electronic scales, before a label displaying all relevant information, including species, grade size, time, and date, is printed off and put on the corresponding box. This information is also transferred automatically to a PC in the wheelhouse, where it is accumulated to provide a running total of Tranquility’s trip.

Served by a dedicated flush deck-hatch and a separate easy-access companionway located aft on the starboard side, the fishroom on Tranquility, which extends over more than half the boat’s registered length, can accommodate some 1,200 stacker boxes, supplied by Box Pool Solutions Ltd, stacked up to 12-high.

In addition, 9t of flake ice made by a 4.5t Buus ice machine can be stored in full-height lockers on the port side, directly under a dedicated refrigeration plant room on the main deck.

Nordkøl ApS of Hanstholm supplied the ice machine, in addition to fitting the 22mm-diameter stainless steel refrigeration pipes mounted on the deckhead.

When landing, an electrical winch is used to pull stacks of boxes aft towards the portside, from where they are lifted ashore through a large hatch by a Thistlelift 8t/m stiff boom landing crane served by a 1.5t winch.

Tranquility was first automated seine-netter

Built by Miller (Methil) Ltd in 2000, the previous Tranquility was the first fly-shooter in the Scottish fleet equipped with power reels for automated seine netting.

Now in the early stages of being refurbished for new owners by Macduff Shipyards, the previous Tranquility was the first automated fly-shooting seine-netter in the Scottish fleet.

23.95m LOA and with a beam of 7.5m, Tranquility INS 35 was built for Lossiemouth skipper Alistair Milne by Miller (Methil) Ltd in 2000, to plans drawn up by Macduff Ship Design Ltd.

Powered by a Caterpillar 3508 main engine of 592kW, Tranquility was the first vessel equipped with a pair of 15t power reels manufactured and commissioned by Smith Maritime of Peterhead.

Tranquility was the third vessel of the same name to be skippered by Alistair Milne, who bought his first boat, Minerva FR 147, from Jimmy Thomson of Fraserburgh in 1989. The 79ft wooden-hulled Minerva had been built by Richard Irvin in 1974 for Philip Morgan of Peterhead as Daisy PD 123. Alistair Milne’s second Tranquility was the 86ft steel-hulled seiner Dondarr INS 104, built at the John Lewis yard Aberdeen in 1975, as Harvest Hope II PD 148.

Lunar Fishing bought the third Tranquility a few years ago, since when Alistair Milne, and subsequently his son Scott, continued to fish the boat, usually working 3-4 day trips after sailing the back ’o Sunday; a well-established routine that the new Tranquility is now beginning to follow.

Work starts to remove the fire damage, after the seine-netter was towed to Macduff for total refurbishment.

Read more from Fishing News here.