The Brixham-based scalloper Joanna C BM 265 has recently completed a nine-month near-bare-hull rebuild, to transform her into a state of the art mid-sized beam scalloper capable of fishing week-long trips wherever the opportunity presents itself around the UK, reports Martin Johns

Owner Derek Meredith initially intended to carry out a planned refit of a limited scale this summer, after he was forced to remortgage the boat following the successful defence of a court case brought against him by Devon and Severn IFCA, for which he is still awaiting reimbursement of substantial costs.

Terminal failure of the boat’s Mitsubishi main engine in mid-December 2018 put paid to the idea of a limited refit, and the boat was immediately towed to Dolphin Haven Shipyard at Galmpton on the river Dart to commence engine repairs.

Joanna C skipper Nathan ‘Chilli’ Clark…

However, after being quoted a lead time of seven months for some parts to rebuild the existing engine, it was clear that a rethink was required. Having successfully re-engined his other scalloper, Golden Promise FH 401, with a Volvo Penta D13MH main engine last year (Fishing News, 19 April, 2018), Derek had no hesitation in ordering a similar unit from Plymouth-based Marine Engineering (Looe) Ltd.

As well as replacing the engine, another pressing job was the replacement of the main deck and deck beams. This was carried out by Colin Champion Marine in 8mm chequer plate.

While the deck was removed, the opportunity was taken to replace other items below deck, and very soon, the scale of the refit began to escalate.

Given the success and reliability of Golden Promise, which underwent a similarly large refit around 18 months ago, Derek Meredith decided to press ahead with a comprehensive rebuild of Joanna C using similar equipment wherever possible, one of the main objectives being to make her as safe as possible for her crew to work.

He is full of praise for the unswerving support of NatWest Bank and its Exeter-based relationship manager Jason Bailey, without whose funding the project would never have left first base, and to Sunderland Marine Insurance, which pulled out all the stops to quickly resolve the main engine issue.

Derek Meredith is very conscious that capable and reliable crew are often now very hard to find and, more importantly, to retain, so greatly enhancing crew comfort levels was high on his agenda when planning the refit.

The entire refit was project-managed by Brixham company Steve Gull Marine Engineering.

Apart from the wheelhouse, which itself had been renewed some years earlier, all deck steelwork and fittings were removed in preparation for a completely new deck layout to incorporate many new features, with the focus also being on fuel efficiency and improved catch quality.

The initial stage of the refit involved replacing or altering all the structural steelwork where necessary. This work was largely carried out by Dan Lloyd of DL Welding from Holyhead, with local Brixham company Stride Engineering fabricating the new whaleback.

… and owner Derek Meredith.

Structural work began with the replacement of around 5m of hull plating on either side of the boat, down to the first chine in way of the working areas. The hull plating was renewed in 8mm steel, as well as replacing all D-section rubbing strakes, and the raised aft bulwarks were replaced in 5mm steel and extended partially around the transom.

Joanna C’s original tubular midships beam gantry was removed, widened and refitted atop two 250mm box-section legs incorporated into the rear of her original wheelhouse structure. As well as supporting the beam gantry, the legs now also support the derrick goose-necks and act as conduits for engineroom ventilation.

Aft of the new gantry legs, the wheelhouse was extended by around 1m under the existing roof overhang to accommodate a galley and mess area, as well as an internal position from which to operate the boat’s extensive new winch system. A new stainless steel doorway has been incorporated into the wheelhouse extension on the starboard side.

Having previously had a somewhat confined shower room located in the engineroom, the decision was made to cover in Joanna C’s previously open foredeck with a 4mm steel whaleback extending to the rear of the wheelhouse, and to incorporate a larger wet room, accessed from the wheelhouse, into the rear starboard side of the whaleback.

The underside of the whaleback is now laid out as a gear storage space, with ample lighting and two new stainless steel escape hatches allowing an emergency escape route from the accommodation area below.

The scalloper’s new whaleback profile has been carefully designed to take account of the distinctive forward sheer of her hull and wheelhouse. A separate stainless steel hatch inside the whaleback on the port side gives access to the engineroom via a stainless steel ladder.

An enclosed winch room has been constructed from 75mm box-section steel and 3mm steel plating at the rear of the wheelhouse.

On the aft deck, a substantial 450mm by 250mm box-section goalpost gantry with cantilevered arms is set inboard around 1m from the bulwarks, to allow space for the catch conveyors and to allow the dredge beams to extend aft right to the transom.

Any ‘moving’ steelwork such as doorways, scuppers and hatches has been reconstructed in stainless steel to prevent corrosion issues and save on future refit costs.

Final stages of Joanna C’s big refit underway in Brixham harbour.

All steel used in the structural work on the boat was supplied by Austen Knapman of Paignton and Hubbard Marine of Brixham.

The new Volvo Penta D13MH engine, developing 205kW at 1,500rpm and installed by Breakwater Marine, has been coupled to Joanna C’s existing Twin Disc 4.5:1 gearbox, which was only rebuilt around a year ago.

With the Volvo Penta D13 rapidly developing an enviable reputation for its fuel frugality, Derek Meredith is expecting the new engine to return fuel consumption figures of around 700 litres per day, a saving of 300-400 litres per day over the previous engine.

Most of the equipment in the engineroom has been replaced, and it is now a much safer environment for the crew. Two new 750-litre stainless steel tanks for freshwater have been fitted, as well as a 500-litre hydraulic oil tank and a Sure Flow calorifier tank on the forward bulkhead supplying hot water to the galley and wet room. The calorifier has three sources of heat: main engine, generator-derived 240V and quayside 240V.

A 5kVA inverter has been installed along with a new deck wash pump, electric bilge pumps and a 240V emergency pump. A new watch alarm, fire alarm and bilge alarms have been fitted, and 240V power is now available throughout the scalloper, including in the working areas on deck. All rewiring and electrical work was carried out by Brian Murray of BUZ Marine.

A new stainless steel propeller shaft was supplied by local Abbotskerswell company C&O Engineering, and a new four-bladed propeller came from Kort Propulsion.

All of the vessel’s pipework has now been replaced in stainless steel, including three sets of keel cooling pipes to serve the main engine, auxiliary engine and fishroom refrigeration system.

Joanna C’s existing forward wheelhouse was stripped bare in preparation for refitting with an entirely different layout. A three-tiered floor has been installed to take account of her forward sheer, with her skipper’s seat installed to port and a multi-level control and instrument console extending just past the centreline to starboard before sweeping aft.

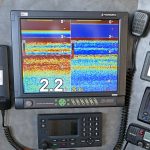

Electronics are a mixture of new and existing, with new units including a Furuno radar, a Hondex HE1500 colour sounder, a Swann eight-camera CCTV system, and four Neovo screens arranged above eye level and recessed into a wraparound eyebrow section incorporated into the wheelhouse roof. The new electronics were supplied by Globe Marine, which also installed a new TV and Sky system and a sat phone in the accommodation area.

The popular Volvo Penta D13MH has been installed in Joanna C.

A set of semi-spiral stairs descend forward on the starboard side of the wheelhouse, where a half-landing allows access into the heads/wet room area under the whaleback, before turning to port and descending further into the forward accommodation area, where four bunks are installed port and starboard in the conventional manner. The sizeable GRP-lined wet room is fitted with a Mira mixer shower, toilet and hand basin.

Stepping down a tier into the centre section of the wheelhouse, a mess table with peripheral bench seating is built into the port side, while a tower unit to starboard houses a built-in microwave oven and conventional oven. A galley and worktop area is installed behind the seating, where a sink unit is situated to port, with a pressure cooker and grilling machine available for further cooking options.

New windows in the wheelhouse extension area were all supplied by Seaglaze Marine Windows Ltd, and comprise a wide central window with smaller opening windows fitted to port and starboard.

The quality of the woodwork throughout the accommodation and wheelhouse would do justice to a luxury yacht, and was completed by legendary Brixham shipwright Bob Cann and his team of carpenters. All areas have been lined with low-maintenance light-coloured laminate with oak edging trim. Upholstery was completed by Simon Pedley from Paignton.

Arguably, the centrepiece of the entire refit is the wheelhouse-controlled ten-winch system, controlling all aspects of hauling operations from a winch console fitted across the rear wheelhouse bulkhead and giving excellent visibility over the working deck area.

Hercules Hydraulics Ltd from nearby Paignton worked closely with Derek Meredith to design and install a custom hydraulic package to suit his requirements. The hauling system and winch locations were designed from the outset to be as efficient and as safe as possible for crew operations, around the needs of seven-a-side scalloping.

The main hauling winches are two Hercules 3.5t top layer pull split winches with integrated hydraulic brakes, manual emergency brake release and a drum capacity of 400 fathoms of 20mm-diameter warp. Initially, 140 fathoms of 18mm-diameter warp are spooled onto the split winch drums, although these will later be changed to 200-fathom 20mm-diameter warps.

The towing warps are led through hooded rollers atop the winch casing before travelling aft above head height to centrally mounted hanging blocks on the gantry crossbeam, then on to another set of blocks on the cantilever arm ends, and finally out to the derrick ends.

Joanna C in towing mode in Torbay.

Derrick topping duties are carried out by two Hercules 2.5t winches installed on either side of the wheelhouse roof just aft of the gantry legs, with the topping warps being continued aft from the derrick ends to form running backstays. Along with all the other stays, warps and rigging, these were supplied by MarineCo from Saltash. Heavy box-section arrester posts are fitted inboard of the catch conveyors to prevent the dredge bars swinging too far inboard.

Two Hercules 2.5t tipping winches, powerful enough to lift all the dredges at once, are installed on either side of the aft gantry crossbeam.

Atop the winch casing are fitted two 1t Rotzler pull-down winches, angled downwards to blocks on the main deck.

Finally, half-tonne landing winches are installed on either gantry leg. These are remotely operated by a small handheld wireless radio-controlled joystick, so the crew can land from any position aboard the boat or on the quayside.

The hydraulic system also powers Joanna C’s existing catch conveyors, which have been extended to suit seven-a-side gear and have been refurbished by John Reid & Son Scallop Gear and fitted with new conveyor belts by Saltash-based Vulcanising South West.

The winches are powered by a very efficient and reliable load-sensing system, including a main load-sensing pump driven directly off the fore end of the main engine, and a full load-sensing valve set-up with integrated fine filtration and system cooling.

The entire system is controlled via a custom-built control panel, with all functions joystick-operated from the wheelhouse. The joystick panel comprises all winch joystick controls, emergency brake release controls, and e-stop and hydraulic system monitoring alarms. Britannia Engineering worked in conjunction with Hercules Hydraulics on the installation, and carried out the system wiring.

Aft of the winch casing, a new taller stainless steel fishroom hatch leads to a newly insulated fishroom, which has been fitted with a refrigeration system by locally based SPX Refrigeration to further extend the scalloper’s trip capability.

A new winch enclosure was constructed aft of the wheelhouse. It is seen here prior to final painting.

Driven by an auxiliary engine-powered Bock F2 compressor with an electric clutch and keel cooling, the system comprises 160m of stainless steel pipework installed on the forward bulkhead and deckhead, with stainless channel and plastic pipe clips ensuring that the entire system is non-corrosive. A digital thermostat is fitted in the wheelhouse, so that the skipper and crew can monitor the fishroom temperature during the trip. SPX proprietor Paul Creed fully expects the new refrigeration system to achieve a minimum fishroom temperature of 0°C.

Once the bulk of the rebuild work was completed, Joanna C was shot-blasted inside and out, before being zinc-sprayed and painted with two-pack Jotun and Hempel marine paints by Devon-based Rocket Blasting Ltd. The vessel then steamed to C Toms and Son of Polruan, where she was lifted ashore using the company’s 220t-capacity boat hoist, to allow replacement of some bottom plates and the fitting of a new transducer.

On completion of this work, the scalloper returned to Brixham for finishing, commissioning of the hydraulic system, and the refitting of the fishing gear.

Initially working locally with a crew of three – skipper Nathan “Chilli” Clark and crewmen Carl Barber and Adrian Dunne – Joanna C has made an impressive start, with very few teething troubles, using six-a-side scallop gear constructed by Reid Scallop Gear.

Both owner and crew are impressed with the new safer working layout, which ensures all deck operations are clearly visible from the winch operator’s position, with the relocation of the derricks further forward ensuring that the crew no longer have to work around lowered derricks. The scalloper will later switch to seven-a-side gear, and is currently taking part in the annual scallop fishery in the Baie de Seine.

The rebuild project has been a triumph in demonstrating what Brixham has to offer in terms of fishing infrastructure. Many of the contractors involved are based in Brixham or within a few miles of the town, with virtually all of the rest being Devon-based. Derek Meredith now has what is, to all intents and purposes, a new boat featuring state of the art technology, all for a fraction of the cost of a new build of comparable size.

Far from being a ‘one trick pony’, Joanna C is also equipped for beaming, using new 4m stone mat beam trawls made by Brixham Trawl Makers Ltd, or 6m beam gear when targeting cuttlefish. There is also provision built into the new hydraulic system for the addition of split net drums aft, if the boat ever needs to be turned over to trawling.

Joanna C BM 265

Joanna C is one of a sizeable fleet of highly efficient under-15m steel scallopers with varying degrees of automation operating from the South Devon port.

She was built in 1980 by Robertson McNaught of Neyland in Wales for Brixham skipper Bruce Cooke, the fourth Brixham-registered boat he owned to bear the same name.

Final stages of Joanna C’s big refit underway in Brixham harbour.

Originally conceived as a multipurpose boat capable of trawling, scalloping, beaming and midwater trawling for sprats, Joanna C was one of the first Brixham boats to be fitted with the familiar local deck layout featuring a four-legged midships beam gantry and traditional aft gallows. At the time, she was regarded as one of the best-looking steel trawlers in her class, with excellent sea-keeping qualities, and always drew admiring gazes from other fishermen.

She spent several years in Brixham, during which time she hit the headlines after catching a wartime mine in her dredges, which then exploded, severely damaging her fishing gear and that of her partner boat, Livine BM 221, which was towing close by.

Joanna C moved a little way up the Devon coast to Exmouth in 1984 under the command of John Green, before changing hands again within Exmouth in 1987. During her time in Exmouth, she was again in the headlines when a submarine snagged her trawl and towed her astern at quite a rate before the crew had a chance to run the warps off the winch and free the boat. Miraculously, no crew were injured in either incident.

Further moves along the south coast followed, and she later belonged to owners at Teignmouth, St Mawes and Brixham respectively, before being purchased by Leach Fishing of Shoreham in 2007, who substantially refitted the boat. Work included replacing most of her wheelhouse and shortening her by around a metre to under 14m to comply with local fishing byelaws, as well as replacing all of her deck ironwork and winches. The boat was purchased by Derek Meredith in 2013, and has concentrated on scallop dredging, based mainly at Brixham, ever since.